Bi-metallic Screws and Barrels

Categories : Screws and Barrels

Over Welding of nickel based alloy on top of the thread surface (screw) and internal diameter (barrel). +Evenly hardened surface with 2mm thickness. +Hardness will not decrease under normal temperature. +The hardened surface is 2 or 3 times more wear-resistant than regular surface. bimetallic

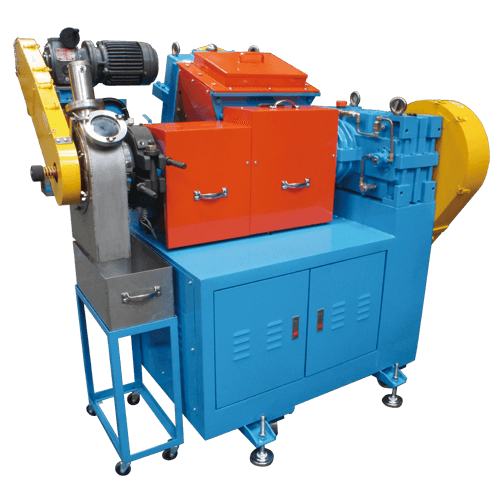

LAB EXTRUDER-Pelletizer (PR-50)

Categories : Plastic Pelletizer Machines

One of our main products, this can be attached to numerous different machinery lines, including pelletizing lines, master batch machines and compounding machines. Our machinery can process many different kinds of pellets including: (EVA, HDPE, PVC, PE, CaCo3 Sulfur etc) The PR-series is a combination of twin-screw feeder and extruder, which is able to process a round mass of raw materials produced by a banbury mixer. This twin-screw design feeds raw materials so stably that it’d decrease the risk of material supply shortage, and further, it’d increase both the yield rate and product quality. Besides, it would create a stable production line by reducing your labor cost and time with this unique design.

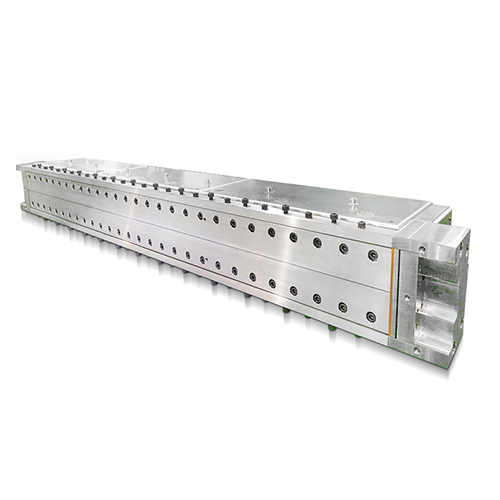

Extrusion Dies MELTBLOWN DIES

Categories : Extrusion Dies / Dies Heads

SUITABLE AVAILABLE FOR POLYMERS INCLUDING PET And PP High processing precision. Internal heating with heating rod, external heating with heating board, temperature control by heating oil cycle to ensure products of good uniformity. Meltblown filter in continuous and automated production to cut production losses more than 35%, cu costs, reliable product quality. Cut production materials consumption sharply. Featuring high yield, low power consumption, low loss, easy operation. Integrated meltblown Extrusion Die. Integrated meltblown Extrusion Die featuring precision aperture, good consistency and without maintenance wear out. Improved meltblown fiber quality and uniformity, improved product quality. Improved Extrusion Die life cycle and life span. Reduced Extrusion Die change operating time, cut maintenance cost and power consumption. Installation capacity down 30 ~ 40 KW. Cut production costs sharply.

Heavy Duty Double Toggle Injection Molding Machine

Categories : Horizontal Injection Molding Machines

The new design has ensured maximum space between tie bars, as well as a large daylight area. The fixed and moving platens are designed in such a way that the yensure complete accuracy and precision. The injection carriage uses a balanced double hydraulic cylinder to provide a secure hold between the mould and the nozzle to eliminate nozzle leakage. Linear guide ways reduce mechanical friction, decrease machine wear and increases accuracy over back pressure providing better control of the injection sequence. Bosch proportional valves are equipped with LVDT positional feedback and pressure transducer. The speed of the proportional valves is more precise resulting in more accurate control.

HIGH PRECISION HYDRAULIC CUTTING PRESS CSS-607

Categories : Foaming Machinery

The Structure Of Press Body Is Made By Special Steel Shaped Materials That Features Pressure-Resistant Function To Maintain A Permanent Plane, With Its Integrated Shaping Of Punch And Slide To Fully Shows A High Resistance Of Wear And Tear, Excellent Strength And Stable Pressing That Would Help Prolong The Service Life Of The Mold. The Cutting Tool Can Be Used With Laser Cutter For Either Pressing Or Die Pressing, Thus Making Product No Burrs And Enabling Clear Angles. The Blowing Device Can Be Worked Further With Mechanical Action, One Punch And One Blowing Subsequently To Absorb Automatically The Well-Cut Finished-Goods That Makes An Easy Access And Safe To Take Feeds, Along With An Installation Of The Almighty Grooved Base Plate, The Mold Locking Is Convenient And Rapid. With A Device Of Fixed-Point Type Pedal Switch, It Shows Up A Mature Technologic Design For Industrial Use. With Its Semi-Automatic Knife Mold Design, It Enables Operators An Easy And Safe Operation.

PRECISION HYDRAULIC AUTOMATIC DIE-CUTTING MACHINE/4COLUMU TYPE CSS-603

Categories : Cutting Machines

Advanced & durable hydraulic circuit and steady electronic control system circuits adopted in the hydraulic system enable to achieve high operating performance. 4 steel posts design instead of guide-ways for punching movement and equipping linear guide-way for the front & rear feeders. The unit performs precisely, stably, quietly, nimble and powerful. lt'sconvenient even for the use at the upstairs of a factory. Cutting depth can be precisely set up to a tolerance of 0.008 mm. Through the use of the longwearing special designed steel plate to replace conventional cutting board, can prolong lift of cutter and obtain better cutting quality and efficiency Processed item may be full or half cut-off. ltems with adhesive may be used as well Products are free from rough edges. The machine is equipped with a protecting device to ensure safety of people and the machine. Automatic cooling system and full-auto cutting device are available for additionally purchase and fitting. Designed in high-precision construction, this machine can be used to perform full-cut and half-cut fabrication tasks. Up/down punching travel uses four high-rigidity guide poles, with linear rail designed for the feeding mechanism. Two-step pressure control to achieve flexible and lower noise operation. It is suitable for multi-level factory buildings. Automatic cutter adjusting mechanism can perform automatic adjustment according to the desired setting, providing 0.01mm accuracy (0.001mm optional). High-precision german steel plate is used to achieve higher durability and wear free operation. This machine uses advanced and durable hydraulic system and electronic control circuits. The machine is equipped with protection device to ensure the safety of the operator and the machine. (with CE optional)

High Speed Injection Molding Machine (TSV Series)

Categories : Hydraulic Clamping Injection Molding Machines

• The double hydraulic cylinder provides secure hold on pressurefor the injection carriage eliminating nozzle leakage. • The toggles are lubricated with the graphite bronze bushes to ensure lower friction wear, assure greater accuracy and greatlyextended life of the clamp unit. • Fast clamping system equipped with regeneration circuit increase speed by 60% to shorten cycle time and save energy. • Bosch proportional valves are equipped with LVDT positional feedback and pressure transducer. The speed of the proportion-al valves is more precise resulting in more accurate control.

Auto Batch Vacuum Foaming System SA-1BVF

Categories : Vacuum Forming Machines

The SA-1BVF can be used with an existing auto batch foaming machine or with SUNKIST's own SA-1B, SA-1BS, SA-1BM and SA-1HA. After the mixture is loaded into mold box, the mold box is moved into this chamber via a carriage. After the mold box us placed inside the curing chamber, the door of the chamber automatically closes and shut tightly. An operator can then adjust the pressure inside the chamber with the control panel. The quality and physical properties of the foam that is formed will be affected when the pressure is changed, ie. the volume of the foam size will increase, foam tensile strength will also increase dramatically, and the hardness of the foam will change. This machine is environmental friendly, reduce the amount of chemicals used and reduce the fire risk.

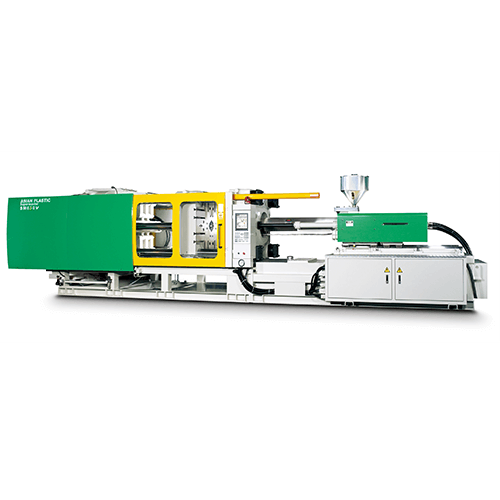

Double Toggle Injection Molding Machine (SMV Series)

Categories : Horizontal Injection Molding Machines

• Double cylinder design reduces injection unit distance. • Ion nitrided essential components-barrel,screw etc. ensure lasting life. • Easy-adjustable and reliable Multi steps injection pressure and speedcontrol. • Steel bushes have a hardness of HV800 for wear resistances. • Auto-lubrication system is provided to assure the constant lubrication of the toggle mechanism • Multi-stroke hydraulic ejector ensures positive ejection of the product and enables unmanned production with or without the use of a robotic arm. • Differential hydraulic circuit shortens cycle time and saves energy. • Low pressure mold protection system was used to avoid mold damage or excessive wear.

Disc Coupling

Categories : Gears

(1) NO-LUBRICATION REQUIRED: No lubricants are needed and no noises or wear and tear produced because there is no sliding or friction. (2) MAINTENANCE-FREE: ”LEAVE IT FOR GOOD AFTER INSTALLATION” It lasts forever as long as is used correctly. (3) LIGHT WEIGHT W/HIGH TORQUE: By operations, it is available in a wide range; it can be made of aluminum alloy to reduce the weight. (4) LARGE OFF-CENTER ALLOWED: With large range of off-centering, it can be used flexibly in all kinds of transmission systems. (5) SUITS HIGH-TEMPERATURE APPLICATIONS: All-metal-pars construct makes it suitable for high temperatures. (6) BACKLASH-FREE: WITH GOOD TORSIONAL RIGIDITY Perfect for axial rotation that requires accuracy and machines with phase-control. (7) CAN BE USED IN EVEN HIGHER SPEEDS: It is highly balanced due to being backlash-free and light weight. (8) EASY TO INSTALL: Comprising small number of pasts and being compact, it can be installed/uninstalled quickly. (9) ROBUST STRUCTURE AND HIGH SAFETY COEFFICIENT: With load stress kept at low standard, it works with very high safety coefficient. (10) AUTOMATIC PROTECTIVE DEVICE: In case of damage, an automatic protective device rotates via pads.

Hydraulic Clamping Injection Molding Machine DHT Series

Categories : Hydraulic Clamping Injection Molding Machines

Direct hydraulic clamping injection molding machines are designed without toggle mechanisms that enable to avoid the toggle wear. This model can increase the position accuracy and is good for high technology and high precision plastic products.