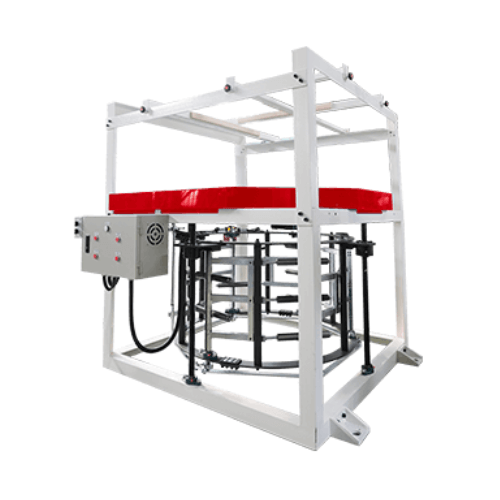

Bubble Cage by Motor Control

Categories : Blown Film Extruder Parts

Blown Film Extrusion Machine is a process that extrudes the molten polymer through Blown Film Die Head to process the plastic film. If the bubble tube is unstable when it first comes out from the Die Head, it needs a support to maintain its stability to prevent it from transforming. Therefore, Bubble Cage by Motor Control play important characters here to stabilize and reinforce the blown film bubble tube while blowing. As the cooling system runs well around the circumference of the bubble tube, the Bubble Cage by Motor Control maintains the stability of the bubble tube over Die Head and Air Ring. It prevents the bubble tube from losing stability and offers higher quality of film which shows the importance of Bubble Cage by Motor Control. HSIN LONG

Ultrasonic Plastic Welder KWD1235

Categories : Automatic Welding Machine

KING ULTRASONIC Ultrasonic Plastic Welder

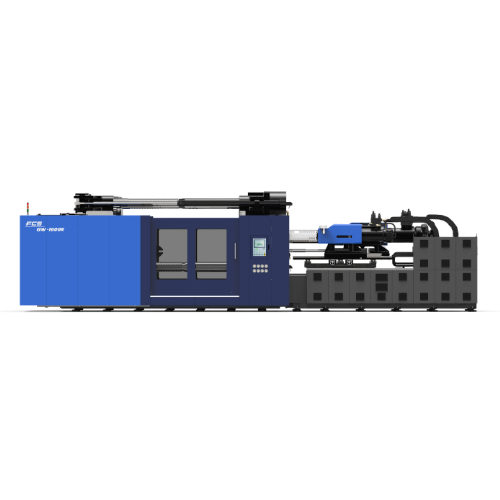

Two-Platen Multi-Component Injection Molding Machine (GW-R Series)

Categories : Injection Molding Machines by Platen

It is a newly launched large-scale two-plate multi-component injection molding machine, widely adopted in the automotive, home appliance, and furniture industries for manufacturing large two-color and multi-color products. It is particularly suitable for large household appliance casings, integrated headlamp cover, run-through connect taillamp covers, car windows, and automotive plasticized sheet. The clamping force ranges from 1,000 to 3,300 tons.

Vibration Welding Machine HWV-15HLS

Vibration welding uses frictional heat to join the interface of two thermoplastic parts under mechanical pressure, the upper clipper clips the thermoplastic to do a high frequency reciprocating according the setting amplitude, it will have frictional heat generated to fully melt the interface, then stop moving and continued to put pressure and cooled to weld two thermoplastic parts

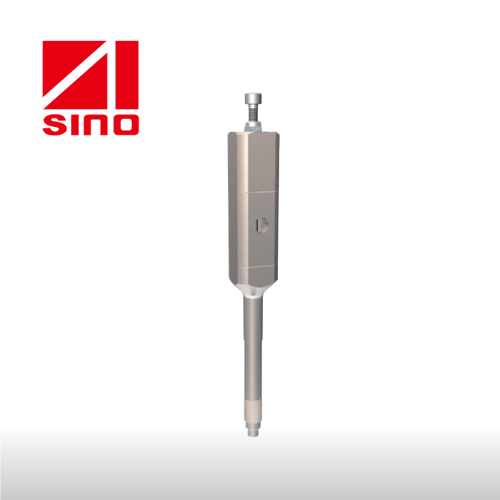

High Pressure Liquid Injector-PSX

The PSX high-pressure liquid injector was developed by Sino-Alloy Machinery as an important accessory to their extruder line. The PSX high-pressure liquid injector is made up of a storage tank, proprietary precision plunger pump, and one-way valve type fluid injector. It can generate pressures as high as 50 kg/cm. This feeder can be connected to any feeding port of the extruder. The PSX high-pressure liquid injector is also capable of injecting high pressure gases or super-fluid liquids. Not only is it suitable for the injection of liquid and gaseous additives in rubber or plastics materials, but also for may plastic and rubber reactive processes or the injection of liquid ingredients in food and pharmaceutical. The PSX high-pressure liquid injector can also be supplied with heating and insulation devices, loss-in-weight metering devices, or flow controllers for precise measurements of the input quantity.

Two in One Twin-Screw Pre-forming Machine

Categories : Twin Screw Extruders

Pre-forming for Rubber, Plastic & Chemical Industries his new model TAPER TWIN-SCREW SHEETS PREFORMING MACHINE usage for the rubber compound mixing after DISPERSION KNEADER conveying to the hopper of this machine to go extruding .The barrel is moveable for easy clean.This machine not only simply to operate but also upgrading the work efficiency, and may go with the mixer to do the integrated production to cater for the keen market competition

Ultrasonic Plastic Welder KWD1230

Categories : Automatic Welding Machine

KING ULTRASONIC Ultrasonic Plastic Welder KWD1230

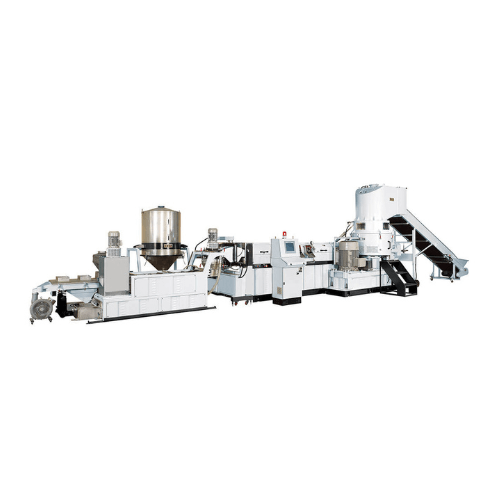

Side Shredding Type Recycling Pelletizing Extrusion Line | CK-SC

Categories : Plastic Pelletizer Machines

CK-SC series Side Shredding Type Plastic Recycling Pelletizing Line is ideal for recycling clean or washed plastic film, fiber, carpet, fabric, jumbo bag, etc. Possible materials : PP, HDPE, LDPE, PET, PC film, Nylon fiber, PP carpet, Jumbo bag, EPE, EPP, EPS, etc.

Sieving Machine

Categories : Separators

Sieving device for PET recycling separates solid wastes such as sands, metal, small stones, labels in PET bottle recycling production. Bottle sieving is useful to reduce equipment running abrasion, production loss to enhance production performance with water-saving. PET flakes sieving improves the final PET flakes quality and stabilizes the quality of flakes. 3 types of sieving machines which are dry trommel, disk screener, and dust remover are available for different materials. They have the same function to remove impurities such as sands, metals, small stones, labels in different washing sections. The disk screener is more compact than the dry trommel, it's good to be placed after de-baling and pre-washing to separate impurities. It can evenly spread PET bottles on the next process like belt conveyor and filter residual water. Dry trommel can remove caps and sands separately through multiple meshes filtrations. Dust remover has two specifications for the choice. One is named Zig-zag separator, the other is label aspiration separator. These two machines can separate small plastic labels and films by taking advantage of the gravity and machine structure.