Ultrasonic Plastic Welder KWD2620-N

Categories : Automatic Welding Machine

Automatic frequency self-checking at startup. Automatic tuning (frequency control). Resonance frequency compensation during the welding cycle. Full-Bridge IGBT module drives the transducer. PWM (Pulse Width Modulation) amplitude control, linear adjustment from 50%~100%. PWM (Pulse Width Modulation) startup vibration (8 selective ramp start-up settings). Protection against ultrasonic frequency deviation, high voltage and over current. External control box display ultrasonic frequency and welding energy. Frequency compensation as horn’s working temperature increase. Abnormal welding alarm. RS485 communication interface. 3 welding modes:Time mode/ Trigger pressure mode/ Energy mode (target & interval setting). Monitor and transmit each welding parameters and status (requires remove the control box and connect to the computer).

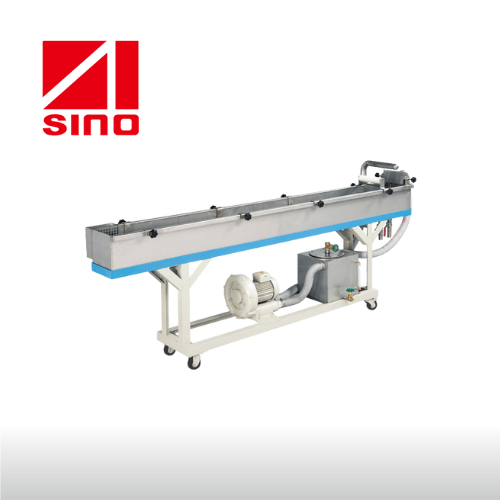

Water Cooling Bath-PSK

The PSK series cooling bath was developed by Sino-Alloy Machinery as an important and essential accessory for the strand pelletizing process. The extruded plastic strand is passed through the cooling bath then dried by an air blade and low pressure vacuum before entering the strand pelletizer to be cut to size. It has a simple design which can be customized with chillers or heaters depending on the production needs.

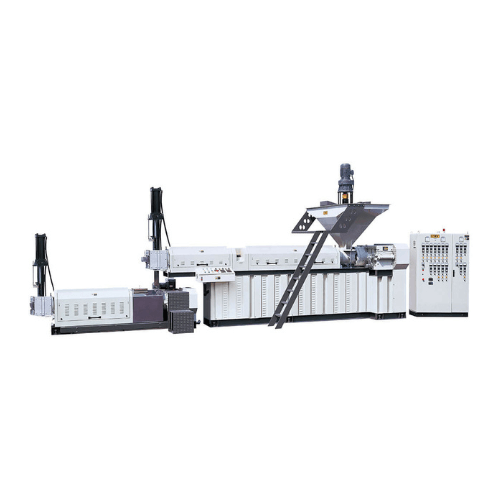

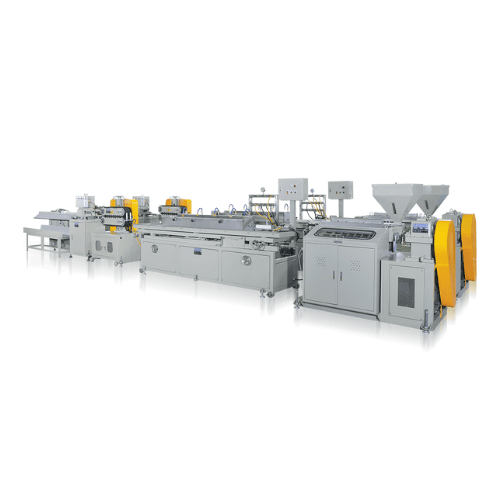

Double Section Recycling Pelletizing Extrusion Line | CK-HSD

Categories : Plastic Pelletizer Machines

CK-HSD series Double Section Plastic Recycling Pelletizing Line is ideal for recycling dirty plastic flakes. Possible materials : PP, PE, ABS, PS, POM, PC, PA, PMMA, PBT, PET, etc.

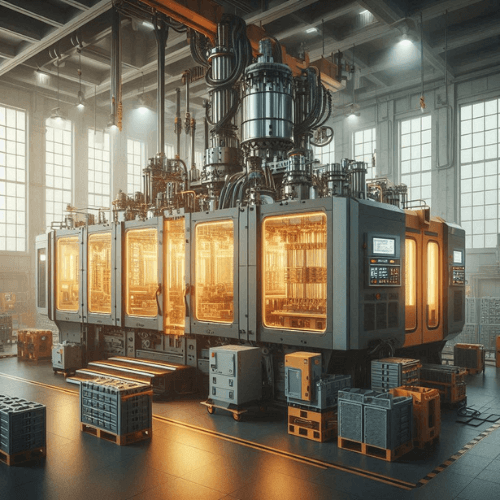

85-150 ton injection molding machine product

Categories : Injection Molded Products

This 85-150 ton injection molding machine is designed for high-precision plastic product manufacturing, including automotive components, electronic parts, appliance housings, medical devices, and consumer goods. Equipped with a high-efficiency servo-driven system, it ensures stable injection pressure and precise control, delivering superior molding quality. With a high-rigidity clamping structure and an optimized hydraulic system, this machine offers durability and operational efficiency. It supports various plastic materials (PP, PE, ABS, PC, PA, etc.) and can be customized with multi-stage injection units and robotic interfaces for full automation, reducing labor costs and increasing productivity. Ideal for OEM manufacturers, plastic molding factories, and precision molding industries, this model meets modern production demands with efficiency and precision.

WPC PROFILE EXTRUSION LINE - PE/PP/PS/TPE/PVC

Categories : Extrusion Lines For Pipes and Profiles

The WPC profile extrusion line is a set of machines used in the production of WPC boards. Differences between WPC profile extrusion and general profile extrusion WPC profile extrusion machine is different from general profile extrusion machine, It has to maximize mixing while minimizing damage to the biomass furnish because the WPC material involves two different types of materials: wood and plastic. It is more accurate processing temperature, melt flow index, etc. are required. The same is that general profile extrusion is a process by which various plastic materials are used to develop quality plastic products that have a feature of continuous (ex: plastic board) but do not include sheet or film products. How does WPC profile extrusion line work? The process of WPC profile extrusion begins with the mixing of wood powder and plastic in the mixer. The ratio of wood powder to plastic varies depending on the desired strength and durability of the final product. Once the mixture is blended, it is fed into the conical twin-screw extruder. The extruder has two screws that rotate in opposite directions, pushing the mixture through a barrel and melting it. The molten mixture is then pushed through a die that determines the shape and size of the extruded profile. The extruded profile is then passed through the vacuum calibration table, which cools it and sets its shape. The haul-off machine pulls the profile through the calibration table, maintaining its shape and ensuring its dimensions are correct. The cutting machine cuts the profile to the desired length, and the stacker stacks the finished product. Advantages of WPC profile extrusion line Efficient and consistent production of high-quality WPC profile products. The extrusion process ensures that the final product has a uniform shape and size, with consistent mechanical properties. Highly automated, reducing the risk of human error and increasing efficiency. Cheng-Yu Plastic Machine is a professional WPC profile extrusion line manufacturer As demand for sustainable, eco-friendly products continues to grow, the wood-plastic composite (WPC) market is booming. We develop WPC profile extrusion lines for profile manufacturers who need a reliable, efficient, and high-quality production process. It is a versatile and flexible solution for profile manufacturers in various industries.

Sieving Machine

Categories : Separators

Sieving device for PET recycling separates solid wastes such as sands, metal, small stones, labels in PET bottle recycling production. Bottle sieving is useful to reduce equipment running abrasion, production loss to enhance production performance with water-saving. PET flakes sieving improves the final PET flakes quality and stabilizes the quality of flakes. 3 types of sieving machines which are dry trommel, disk screener, and dust remover are available for different materials. They have the same function to remove impurities such as sands, metals, small stones, labels in different washing sections. The disk screener is more compact than the dry trommel, it's good to be placed after de-baling and pre-washing to separate impurities. It can evenly spread PET bottles on the next process like belt conveyor and filter residual water. Dry trommel can remove caps and sands separately through multiple meshes filtrations. Dust remover has two specifications for the choice. One is named Zig-zag separator, the other is label aspiration separator. These two machines can separate small plastic labels and films by taking advantage of the gravity and machine structure.

Zig-zag Separator

Zig-zag separator can effectively separate the dust in the flakes, small plastic labels or film by taking advantage of the gravity and the special internal structure design. The label aspirator separates the label and fine impurities from the flakes by the negative pressure which generated by blower, and can be used by multiple assembly.