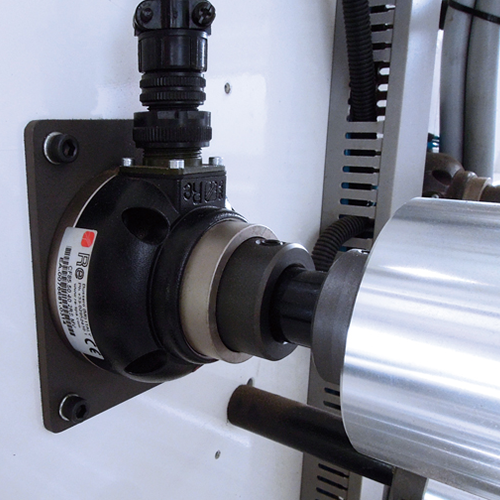

Auto Tension Sensor

Categories : Flexo Printing Parts

The Edge Position Control (Multi degree) is from Italy, Europe, which can automatically detect web tension and send the parameters to control unit.

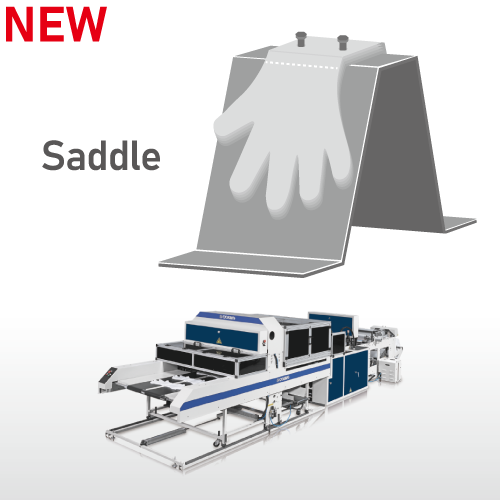

Fully Automatic High Speed Disposable Plastic Gloves Making Machine / SSD-800-HGL(Saddle)

Categories : Bag Making Machine by Applications

-Computer control over the entire process -Jumbo film roll to final pruduct ( 2 line output ) , one process flow -Automatically stop when running out of film / film feeding blocks or jam -Automatically tear off the waste edge film -Melting cut-off ( no cutting knife ) system save time and manpower on adjusting knife -Capable to produce 3 types in same machine

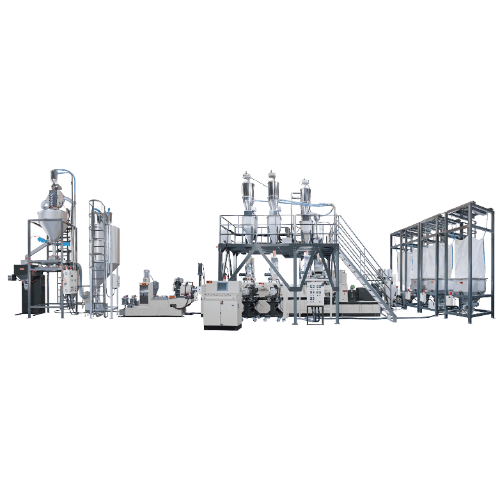

Co-rotating Twin Screw Automatic Metering / Weighing / Conveying Pelletizing Compounding Line | CK-HT

Categories : Twin Screw Extruders

CYKF is committed to the R&D and manufacturing of the automatic extrusion systems, and constantly strives for perfection. The CK-HT series Co-rotating Twin Screw Automatic Metering Weighing and Conveying Pelletizing Compounding Extrusion Line successfully overcomes the problem of customer limited site space and configures the optimal traffic line for customers. The high-efficiency system shows the advantages of safety, convenience, efficiency and quality, reflecting the greatest value of CYKF.

Turret Rewind Slitting Machine FSL-TR1300

Categories : Slitters and Rewinders

HCI's newly launched FSL-TR1300 turret rewind slitting machine is designed for automatic slitting and rewinding operations, with automatic splicing and roll changing, stand-by paper core auto positioning, finished roll pusher and unloading device to increase productivity and reduce the operation down time. The HMI operating system equipped with a color touch screen provides easy-to-learn operations and memory of operating parameters, which makes the product quality stable.

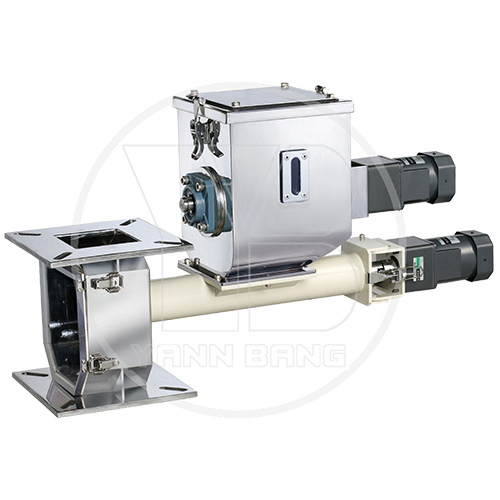

Master-batch Feeder for Powder (MFP)

Categories : Feeders

Easy operation: Enter the weight of the resins, screw back time, dosing capacity per turn and additional rate of the masterbatch, it will calculate proper R.P.M. rate automatically. The function is available to store up to 10 sets of R.P.M. Setting memory. Flexible extension: Each feeder controls and operates individually. It is easy to add extra a feeder or change the type of screw later. A dosing and mixing system of various resins is available for your early inquiry. Precise calculation: With the special process, the internal part of the unit has no dead corners and makes the dosing process more accurate.

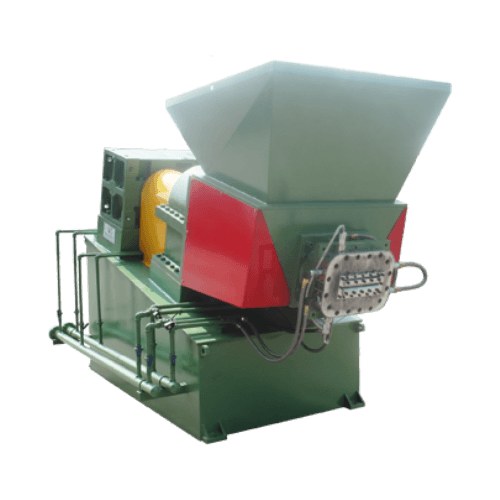

Taper Screw Batch Pre-former

Categories : Dryers and Dehumidifiers For Plastic Materials

FUNCTION: This uniquely designed Taper Twin Screw Extruder has a large volume open top hopper, which will accept a whole batch from your mixer without performing. The twin screws continuously and automatically bite and feed the compound, which then is extruded through a die. This simple but effective feeder, allows you to eliminate many labor intensive material handing processes, between your mixer and existing conventional extruders or other equipments.. BENEFITS: Large volume hopper capacity Exceptional cooling and temperature control Full and easy access for cleaning Simple, automatic and continuous operation Easy maintenance Cost effective and affordable

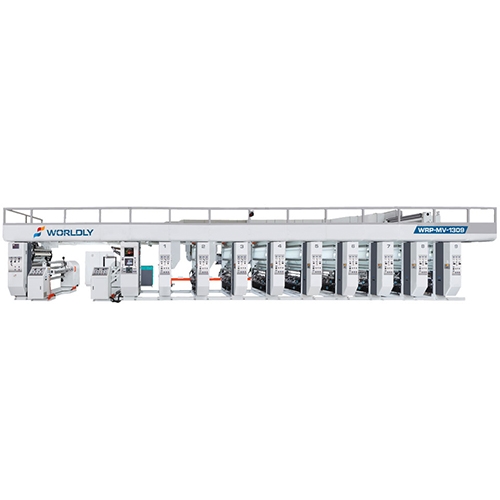

High Productivity Rotogravure Printing Machine(WRP-MV Series)

Categories : Rotogravure Printing Machines

Worldly company has good experience and technology development in new rotogravure machine over the years. The printing press equipment with powerful combination of central control system, and ease for operation. Simply and easily function and control parameter display on the human-machine interface touch screen, synchronized with PLC control system, also automatic alarm system provide the most efficient printing management for operators and leads to reduced default rates and less waste. Otherwise the exhaust recycle system can recycle the air up to 75% energy,The design leads to high productivity, lowers production costs, and provides a competitive advantage.

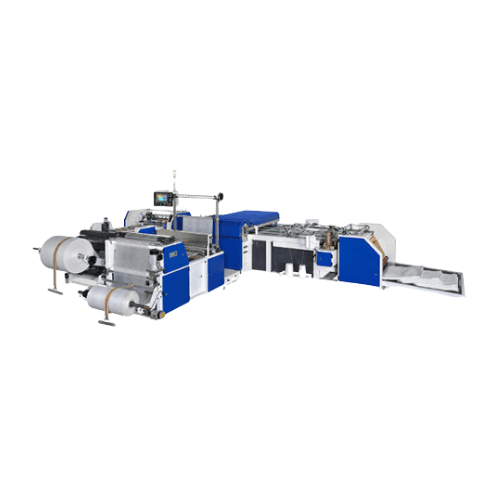

PE Film Liner Inserting Cutting-Sewing Line for Woven Bag CIS-2016

Categories : Cutting Machines

Fully Automatic In-Line Process for Liner Inserting-Cutting-Sewing. Applied for both functions: 1. Liner can be fully sewn with PP Woven Bag. 2. Liner also can be not sewn / loose inside PP Woven Bag. Without inserting liner, the machine can process for normal Cutting-Sewing function. Saving Manpower Hugely. With Excellence Quality & Stable Performance.

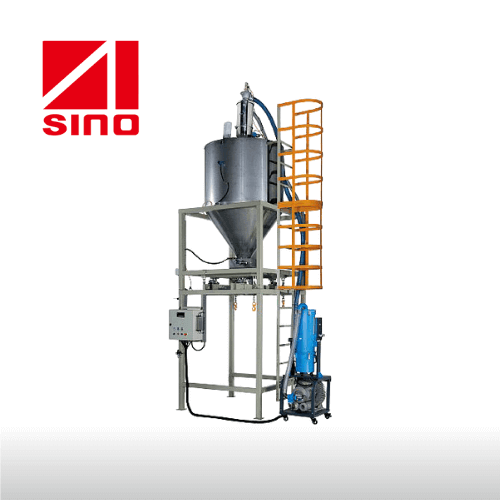

Storage Tank with Blowing-PSP

The PSP series storage tank with optional blower is Sino-Alloy’s solution for the temporary storage of the rubber or plastic pellets before packaging. The PSP series storage tank is made of stainless steel and can be customized to the customer’s specifications. The optional blower/dryer can help ensure there is no buildup of residual moisture. An optional vacuum loader can transport the rubber or plastic pellets from the PSN separator directly to the PSP storage tank. Also available with a packaging function includes air control valves to regulate the output quantity and an automatic weight scale.

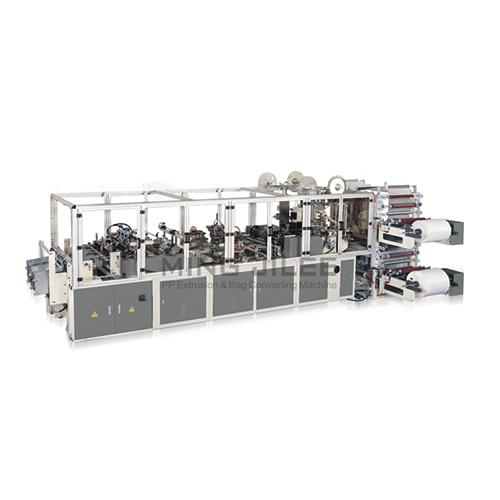

Twin Line Sheet Protector Machine ( Blown Film)

Categories : Bag Making Machine by Applications

MGA-17A-700DSP This machine is designed especially for all kinds of data bag (sheet protector) from the plastic feed material (CPP or IPP) to the finished product. The twin line machine can be operated in two ways: one or the other line machine can be operated independently or they can both be operated simultaneously. Manufacturing of the bag is fully automatic: the triangle folding device of the machine can run on either single layer film or double layer film; the Electronic Edge Position Controller maintains a uniform position for the feed material; the auto tension control maintains the stability of the feed material during the manufacturing process. Each functional aspect of the machine is essential to the stability of the manufacturing process, not only save labor costs, but also raise productivity. This machine is equipped with various precision and durable punching molds with a very low breakdown rate, connecting to the servo motor and digital computing unit for length control to allow a very precise punching position. This machine is equipped with a heat sealing device and twin blade cutting device (with a stationary lower blade and a guillotine-action upper blade) which ensure the size of the bags are uniform. The sealing line is neat and elegant and the waste ratio is reduced to a minimum. In order to reduce the impact pressure on the heat sealing device and to ensure a consis- tently smooth seal, the surface of the feed tray consists of a soft, silicon-based material. This machine is equipped with high quality, high performance parts to incorporate all kinds of control and monitor systems. During operation, anything unusual will automatically stop the machine in alarm to avoid waste material and protect the machine. glove making machine gloves making machine bag making machine plastic glove making machine plastic gloves making machine

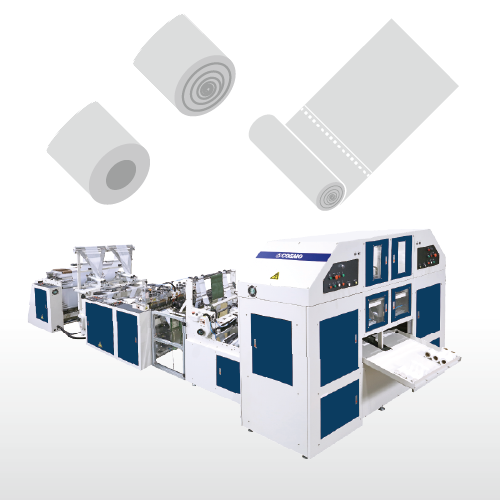

Fully Automatic High Speed Single Line with Core (V, C, N, M Fold) Garbage Bag on Roll & Table Sheet on Roll Making Machine / SMNRCR-1000

Categories : Plastic Bag Making Machines

Computer control over the entire process From film roll to final pruduct, one process flow Automatic film feeding, cordination free from tension adjustment Automatically stop when running out of film / color scanning error / film feeding blocks or jam Easy switch - able core to coreless function

Servo Motor Driven Perforating Bag Making Machine with Automatic Rewinding Module - Four Fold

Categories : Plastic Bag Making Machines

1. Servo Motor Driven, Efficient mechanical structure From film to final bag, one process flow. 2. Unique designed Multi-Functional Folding Device can fold "M" Shape bags. 3. Adjustable Multi-Functional Folding Device can folding any size of bag with out changing the rack. 4. This can produce Coreless Rolls. 5. User-friendly Control Panel, easy to understand easy to operate. 6. Digital control for production length adjusting, precise and less wastage. 7. Simple design, assemble precisely, durable, and easy for maintaining. 8. Easy operating, Pleasant cutting and sealing, with high firmness and no scratch. 9. Real time printing tracing control for accurate registration, when printing error occurred machine will stop automatically. 10. High production efficiency to save man power and time.