AT - 6, 8

Categories : Cooling Equipment / Industrial Chillers

Temperature Range: 5~40°C Humidity Range: 40~80% Cooling Capacity: 1.4~2.3 KW

C Type / Tie-barless Rotary Table - YC Series

Categories : Vertical Injection Molding Machines

C Type / Tie-barless Rotary Table - YC Series - C-type structure, the deformation is small. Easier for insert molding.

Laminating Machine HC-LM SERIES

Categories : Extrusion Lamination Machines

Features This laminating machine extruder volume adopts automatic calculating system. Whole machine is in synchronization control system, and with the latest model of touch-screencontrol panel. Unwinder / Rewinder are double shafts turret type, with splicing device and alternate changing shafts system. Ensure non-stop working condition. Reduce the waste and the production cost.

Vertical Clamping Horizontal Injection Four Columns Series YT SERIES

Categories : Vertical Injection Molding Machines

Vertical Clamping Horizontal Injection Four Columns Series - YT SERIES

Five-layer Co-extrusion Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

Nowadays, flexible packaging replaces the containers that need lots of energy to manufacture as like timber, paper boxes, glass and steel. Because flexible packaging has lower temperature required in processing than above materials, the emission of carbon dioxide can be reduced extremely. It is no doubt that development of flexible packaging becomes the new market trend currently. The usage of flexible packaging is covered in consumer and industrial goods, food, medical treatment and electronic products and it could be as prevention film, protection film, shrink film and so on. The flexible packaging industry emphasizes to how to downgauge the film structure and possess multiple different performances simultaneously. The multi-layer machines could be possible to achieve the expected outcome. The multiple materials in multi-layer machine could give different performances in each layer. Also, it could be more flexible to arrange the distribution of material that let users could manipulate the resins more extensive to reduce the cost in material and production. In current time, at the issue of sustainability, people pay attention to the possibility in recycling to reuse and biodegradable material development. In the flexible packaging industry, it is an opportunity and a challenge for each manufacturer to realize high-performance film, at the same time, to save energy and to be friendly to environment . Please feel free to contact us and tell us the information about the film, King-Plus will provide a tailor-made blown film machine to your requirement.

Multi Co-Extrusion Blown Film Machine for AB or ABA - YHFT-2

Categories : Blown Film Extruders

● Strong and stable machine structure. ● Two extruder, One Died Head

PET Sretch Blow Molding Machine - TEM04S2-88

Categories : Automatic Blow Molding Machines

PET STRETCH BLOW MOLDING MACHINE-TEM04S2-88 FEATURE Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.

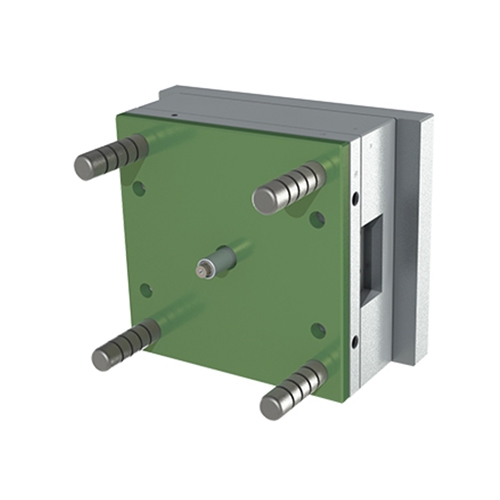

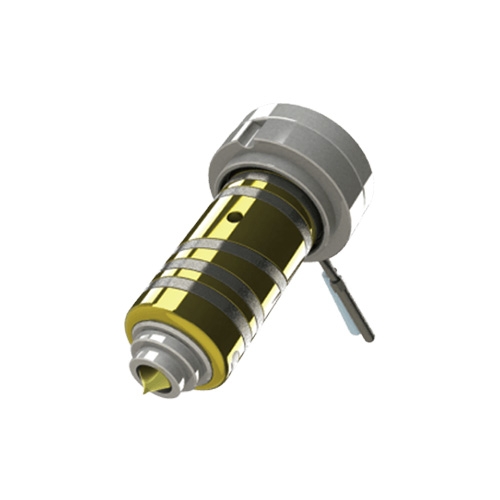

COLD DECK WITH SINGLE VALVE GATE

Shut-off nozzle design:Don't need to cut scrap. System temperature analysis:High efficiency heat isolation and cooling, uniform heating system. Module design of Cold Deck:Quick installation and easy to maintain.

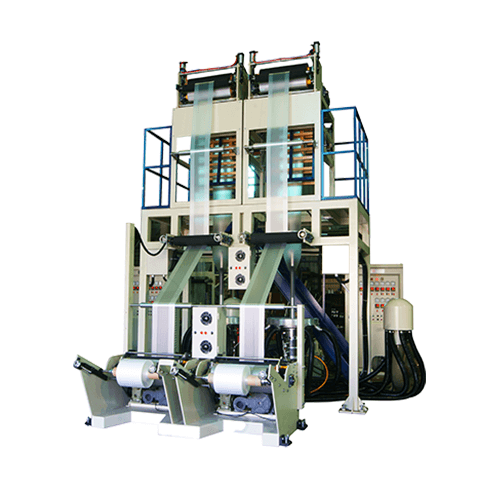

Twin Head High Speed Blown Film Machine

Categories : Blown Film Extruders

Product Model: YHF-2-H Twin Die Head, Single Screw, High-Speed

AT - 360

Categories : Cooling Equipment / Industrial Chillers

Temp. Range: 5~40°C(Indoor ) Humidity Range: 40~80% Cooling Capacity: 84~105 KW

ST-800 / 900

Categories : Industrial Robots

.Improved structural design leads to greatly reduced weight. .20KG lighter than THS series .And more lightweight than HX series by around 10KG .On structure weight reduction, motors inside can work at lower load for a longer lifespan.

Corrugated Medium Liner / Medium Fluiting / Test liner

Categories : Cartoning Machines

- Our main products are Corrugated Medium Liner (GSM 112 to 150), Medium Fluiting (GSM 112 to 200) and Test liner (GSM 125 to 200). - Main applications for manufacturing paper carton box and paper bag. - Paper jumbo roll width can be slit as per required width. Maximum 4 meter wide.

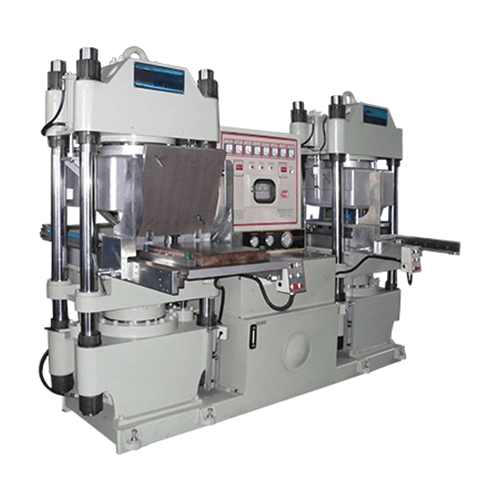

Patent Rail Mold-Open Rubber/silicone Compression Vacuum Molding Machine VCC-DP

Categories : Compression Molding Machines

Nature rubber Rubber of metal boned parts Oil resistance rubber NBR+PVC concoction Synthetic rubber Medical/Pharmaceutical usage rubber Heat resistance rubber.

OPEN GATE-ANPT

Categories : Hot Runner Systems

The most used nozzle. There is a torpedo inside the nozzle to have a circularity gate and guide the melt along the torpedo to flow into the cavity, and therefore can reduce the production of cool plug. Can reduce the cycle time due to the gate will cool down fast. It will be possible to have 4 seconds / cycle with excellent mold design. This series is very popular for unapparent gate mark. When the melt has added with glass fiber or is shear-sensitive and has strict requirement to the flow mark that will need more attention.

3D CAD simulation figure & ABS + CNC proofing

The biggest problem in rain boot mold creation is discussion. In the past, 2D sketches were used to discuss patterns and then reference samples were used to assist imagination between both sides. However, rain boots are composed by the curvature of the curved surface of the high variation.Only by 2D sketches and sample auxiliary may lead to a gap between imagination and practices, resulting in continuous modification. Rain boot mould:PVC wellies, boots or foam material wellies and boots shoe mold, shoe mould, mould on shoes, mould shoes,mould in shoes Rain boots, boots, work shoes, gumboot,pvc shoe,eva shoe,pvc boot,plastic shoe,injection shoe

Vertical Liquid Silicone Rubber Injection Molding Machine

Categories : Silicone Injection Molding Machines

Precision Vertical mold clamping system (Parallelism/ flatness: 0.02/100 mm) with heavy-duty tie-bars works greatly to extend machine & mold life and reduce flash of product.