Classification : Monofilament Making Machine

Country: Taiwan

Phone: 886-5-2374466

Fax: 886-5-2376971 /886-5-2381029

Contact Person: Kun Lin Tsai

| MODEL | KS-MF55 | KS-MF65 | KS-MF75 | KS-MF90S | KS-MF100S | ||||||

| FEATURE | MATERIAL TO BE USED | P.E. & P.P. | |||||||||

| DIA. OF FILAMENT | 0.15 ~ 1 m/m MONOFILAMENT | ||||||||||

| EXTRUSION OUT PUT | 50 kg/hr | 80 kg/hr | 125 kg/hr | 200 kg/hr | 250 kg/hr | ||||||

| EXTRUDER | SCREW DIA. | 55 m/m ø | 65 m/m ø | 75 m/m ø | 90 m/m ø | 100 m/m ø | |||||

| SCREW L/D | 30 : 1 | 30 : 1 | 30 : 1 | 30 : 1 | 30 : 1 | ||||||

| SCREW MATERIAL | SACM 645 STEEL WITH NITROGEN TREATMENT | ||||||||||

| CYLINDER MATERIAL | SACM 645 STEEL WITH NITROGEN TREATMENT | ||||||||||

| CYLINDER COOLING | 1/2 HP × 3 | 1/2 HP × 3 | 1/2 HP × 4 | 1/2 HP × 4 | 1/2 HP × 4 | ||||||

| DRIVING MOTOR | 25 HP | 30 HP | 50 HP | 100 HP | 150 HP | ||||||

| HEATER CAPACITY | 16 KW | 30 KW | 35 KW | 45 KW | 55 KW | ||||||

| DIE | NOZZLE (HOLES) | 80 | 125 | 205 | 150 × 3 , 90 × 5 | 155 × 3 , 125 × 5 | |||||

| CONTROL PANEL | TYPE | INDEPENDENCE TYPE SWITCH BOARD (BOX) | |||||||||

| AUTO-THERM CONTROL | 6 ZONES | 6 ZONES | 7 ZONES | 7 ZONES | 8 ZONES | ||||||

| COOLING DEVICE | WATER COOLING TANK | 570W × 1500L × 600H | 620W × 1500L × 600H | 770W × 1500L × 600H | 920W × 1500L × 600H | 1150W × 1500L × 600H | |||||

| TAKE-OFF UNIT A | DRIVING MOTOR | 3 HP | 5 HP | 7½ HP | 10 HP | 15 HP | |||||

| TAKE-OFF SPEED | 10 ~ 25 m/min | 10 ~ 25 m/min | 10 ~ 25 m/min | 10 ~ 25 m/min | 10 ~ 25 m/min | ||||||

| TAKE-OFF ROLLER (m/m) | 270 ø × 400L × 7PCS | 270 ø × 450L × 7PCS | 270 ø × 600L × 7PCS | 270 ø × 750L × 7PCS | 270 ø × 900L × 7PCS | ||||||

| PNEUMATIC ROLLER (m/m) | 140 ø × 360L × 1PC | 140 ø × 410L × 1PC | 140 ø × 560L × 1PC | 140 ø × 710L × 1PC | 140 ø × 860L × 1PC | ||||||

| HOT OVEN STRETCHING DEVICE | LENGTH (m/m) | 400W ×3000L | 450W ×3000L | 600W ×3000L | 750W ×3000L | 900W ×3000L | |||||

| BLOWER | 2 HP BLOWER × 2 | 2 HP BLOWER × 2 | 2 HP BLOWER × 2 | 2 HP BLOWER × 2 | 3 HP BLOWER × 2 | ||||||

| HEATER CAPACTIY | 16 KW | 18 KW | 22 KW | 25 KW | 35 KW | ||||||

| AUTO-THERM CONTROL | 1 SET | 1 SET | 1 SET | 1 SET | 1 SET | ||||||

| TAKE-OFF UNIT B | DRIVING MOTOR | 5 HP | 7½ HP | 10 HP | 20 HP | 25 HP | |||||

| TAKE-OFF SPEED | 40 ~ 160 m/min | 40 ~ 160 m/min | 40 ~ 160 m/min | 40 ~ 160 m/min | 40 ~ 160 m/min | ||||||

| TAKE-OFF ROLLER (m/m) | 270 ø × 400L × 7PCS | 270 ø × 450L × 7PCS | 270 ø × 600L × 7PCS | 270 ø × 750L × 7PCS | 270 ø × 900L × 7PCS | ||||||

| PNEUMATIC ROLLER (m/m) | 140 ø × 360L × 1PC | 140 ø × 410L × 1PC | 140 ø × 560L × 1PC | 140 ø × 710L × 1PC | 140 ø × 860L × 1PC | ||||||

| HOT AIR ANNEALING DEVICE | LENGTH (m/m) | 400 W × 4500 L | 450 W × 4500 L | 600 W × 4500 L | 750 W × 4500 L | 900 W × 4500 L | |||||

| BLOWER | 2 HP BLOWER × 2 | 2 HP BLOWER × 2 | 2 HP BLOWER × 2 | 2 HP BLOWER × 2 | 3 HP BLOWER × 2 | ||||||

| HEATER CAPACITY | 16 KW | 16 KW | 18 KW | 20 KW | 30 KW | ||||||

| AUTO-THERM CONTROL | 2 SETS | 2 SETS | 2 SETS | 2 SETS | 2 SETS | ||||||

| TAKE-OFF UNIT C | DRIVING MOTOR | 3 HP | 5 HP | 7½ HP | 10 HP | 15 HP | |||||

| TAKE-OFF SPEED | 40 ~ 160 m/min | 40 ~ 160 m/min | 40 ~ 160 m/min | 40 ~ 160 m/min | 40 ~ 160 m/min | ||||||

| TAKE-OFF ROLLER (m/m) | 270 ø × 400L × 5PCS | 270 ø × 450L × 5PCS | 270 ø × 600L × 5PCS | 270 ø × 750L × 5PCS | 270 ø × 900L × 5PCS | ||||||

| PNEUMATIC ROLLER (m/m) | 140 ø × 360L × 1PC | 140 ø × 410L × 1PC | 140 ø × 560L × 1PC | 140 ø × 710L × 1PC | 140 ø × 860L × 1PC | ||||||

| WINDING UNIT | TYPE | MSW & MPW | MSW & MPW | MSW & MPW | MSW & MPW | MSW & MPW | |||||

| NO. OF SPINDLES | 85 | 130 (65×2) | 210 (105×2) | 160 (80×2) | 160 (80×2) | ||||||

| WINDING MOTOR | 3 kg/cm × 85 | 3 kg/cm × 130 | 3 kg/cm × 210 | 3 kg/cm × 160 | 3 kg/cm × 160 | ||||||

| TRAVERSE MOTOR | 2 HP HYDRAULIC POWER UNIT × 1 | 2 HP HYDRAULIC POWER UNIT × 2 | |||||||||

| WASTE ROLL DRIVE | 30 kg/cm × 1 | 30 kg/cm × 1 | 30 kg/cm × 1 | 30 kg/cm × 1 | 30 kg/cm × 1 | ||||||

| SHIPPING DATA | DIMENSION (L×W×H)(M) | 24.0 × 2.5 × 2.5 | 28.0 × 2.5 × 2.5 | 32.0 × 2.5 × 2.5 | 40.0 × 6.5 × 2.5 | 40.0 × 6.5 × 3.5 | |||||

| TOTAL CONTAINER | 40 × 1 , 20 × 1 | 40 × 1 , 20 × 1 | 40 × 2 | 40 × 2, 20 × 1 | 40 × 3 | ||||||

| OPTIONAL DEVICE | NON-STOP SCREEN CHANGER, PRESSURE GAUGE, GEAR PUMP, LINE SPEED SYNCHRONIZE DEVICE, WASTE COLLECTOR, DRYER, CHILLER | ||||||||||

*Specifications are subject to change without notice for improvement.

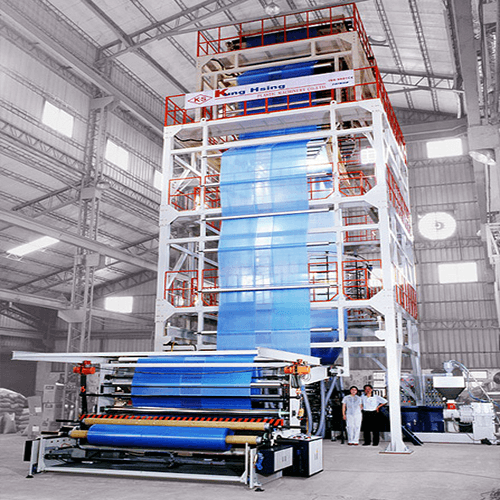

.jpg)

KS-MF65

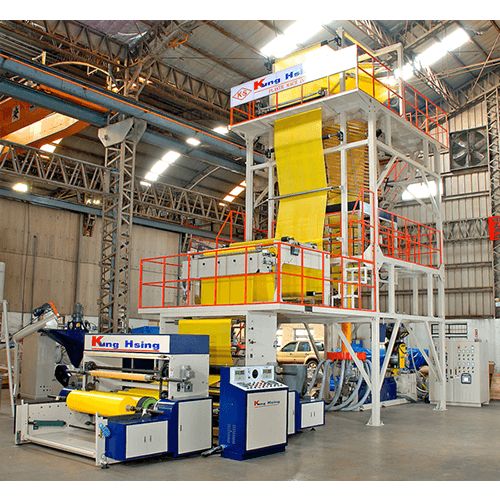

.jpg)

.jpg)

KS-MF75

.jpg)

KS-MF100

.jpg)

.jpg)

.jpg)