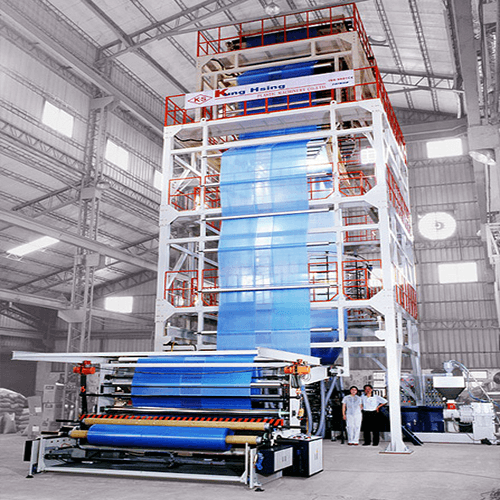

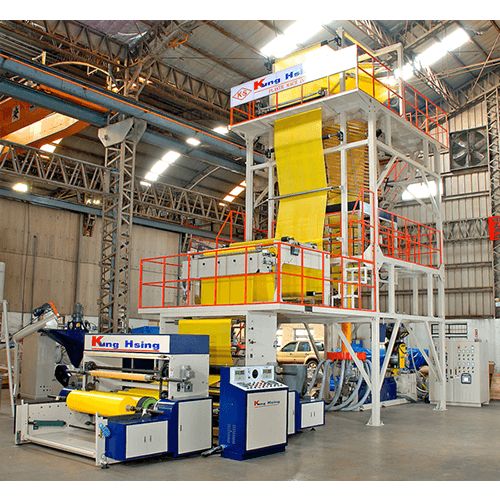

Classification : Blown Film Line

Country: Taiwan

Phone: 886-5-2374466

Fax: 886-5-2376971 /886-5-2381029

Contact Person: Kun Lin Tsai