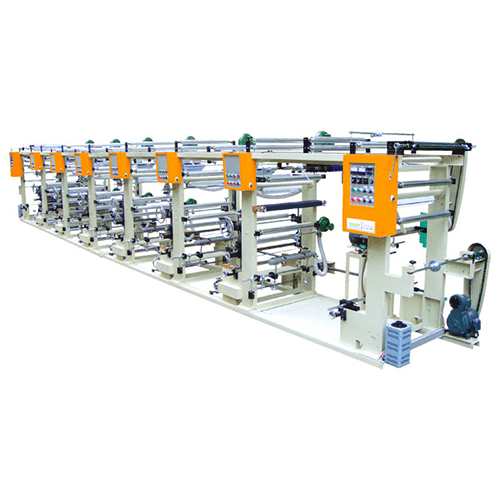

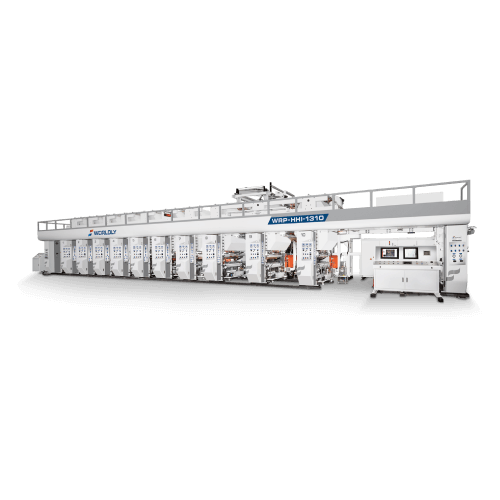

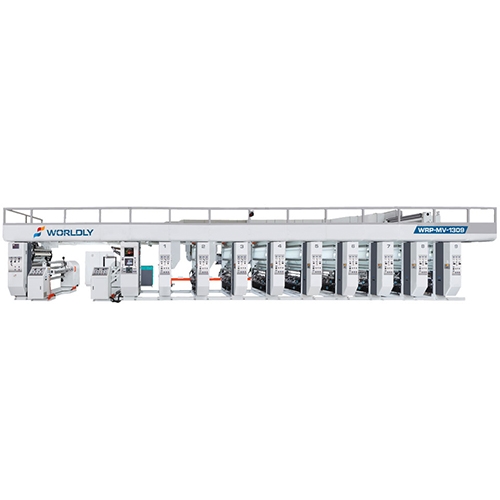

GT ( The Servo Driven Press)

The press is highly automated with servo drive on each print station. This press is designed to combine rotogravure printing quality with short change over times, low waste levels and easy operations. If you are looking for a servo driven rotogravure press, this is the press for you to customize

Standard Specification

- Non-stop turret type unwind and rewind

- Drying chamber: Double sided

- Shaftless type gravure cylinder

- Impression sleeve

- Rapid wash system

- Registration: by servo motor

- Transmission: individual servo motor

Highlight

The press is highly automated with servo drive on each print station. This press is designed to combine rotogravure printing quality with short change over times, low waste levels and easy operations. Equipped with automatic reel change with flying splice capability at maximum press speed. The GT press is designed for…

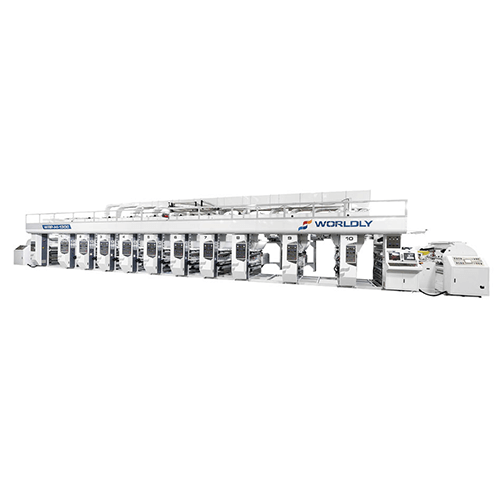

Operation Comfort

- Trolley designed printing

station

- Touch screen interface

- User friendly layout screen control

- Job memory for repeat tasks

- Easy access to printing stations

Print Quality

- Servo motor control guarantee excellent print registration holding

- Rigid cast iron machine frame

- Automated registration control

- Adjustable doctor blade in 3 directions

- Rigid doctor blade design with pneumatic lock ensures absolute ink transfer uniformity

- Fault diagnosis on main drive control

Quick job Change

- Job memory for repeat tasks

- Shaftless Chucking System for print cylinder and sleeve type impression rollers

- Auto pre-register control

Remote Service Assistance

- 24/7 machine online diagnostic

system

- Exclusive PLC Network

Connection Technology to achieve deep online diagnose and prompt

remote-maintenance.

Industrial I.40

- OPC UA Data Exchange Protocol

for communication between devices, machines and enterprise systems (ERP, SCADA,

CRM…etc)

- Remote HMI monitoring via

mobile devices

Safety

- Compliant with Conformité Européene or Australian Standard

- Certification service available with CSA, NEC and IEC

- Available for CO2 nozzles in printing unit and drying tunnels

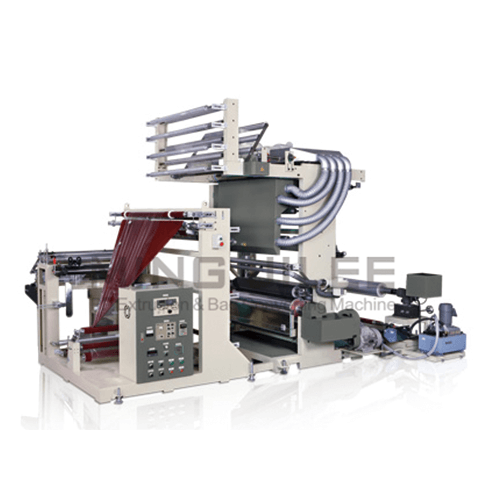

Application

Paper

Food packaging, Pre-print for paper box, Bags, Paper cup, Liquid & beverage, Household cleaning, Cosmetics, Gift wraps, Wallpaper, Paperboard

Aluminum

Food packaging, Industrial packaging, Wine capsule, Foil containers

Film

Food packaging, Industrial packaging, Bags, Liquid & beverage, Household cleaning, Cosmetics, Confectionary wrappers

Woven bag

|

SPECIFICATION |

GT |

|

Number of Colors |

2 / 4 / 6 / 8 /10 /12 |

|

Max Machine Speed (m/min ; ft/min) |

350 ; 1148 |

|

Material Width (mm ; inch) |

600 / 800 / 1000 / 1200 / 1300 / 1500 23.6 / 31.5 / 39.4 / 47.2 / 51.2 / 59 |

|

Cylinder Face Width (mm ; inch) |

700 / 900 / 1100 / 1300 / 1600 27.6 / 35.4 / 43.3 / 51.2 / 63 |

|

Cylinder Diameter (mm ; inch) |

100 ~ 285 3.9 ~ 11.2 |

|

Reel Diameter (mm ; inch) |

600 / 800 / 1000 23.6/ 31.5 / 39.4 |

|

Drying System |

Electric, Gas, Steam |

|

Infeed / Outfeed Unit |

AC Vector / AC Servo (Shaftless Driven) |