Plastic Recycling & Material Processing Machinery

Plastic recycling and material processing machinery plays a vital role in promoting circular economy and sustainable manufacturing. These machines are designed for recycling, sorting, washing, crushing, blending, and pelletizing plastic waste, turning discarded materials into reusable raw inputs. Widely applied in bottle recycling, in-house scrap recovery, masterbatch production, and compound mixing processes.

PRM-Taiwan offers a full range of solutions including Bottle Recycling Lines, Plastic Crushers, Plastic Washing Lines, Plastic Pelletizer Machines, Plastic Shredders, Masterbatch Manufacturing Lines, Mixers and Blenders, and Material Processing Machines to help businesses improve recycling capability and production efficiency.

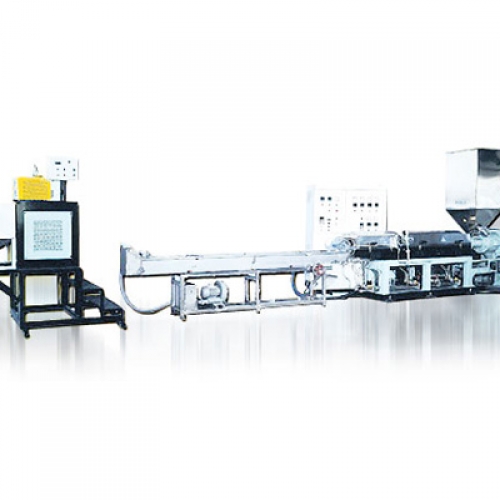

TPE Automatic compounding Line (Under Water Cutting)

Categories : Plastic Pelletizer Machines

1. SBS 2. SEBS 3. OVERMOLDING (For PP, PE, PS, PMMA, PETg, ABS, PC, PA) 4. TPV 5. TPU (Hotmelt Adhesive) 6. TPEE

Horizontal Mixer (Designed For Mixing Oxidizing Agents)

Categories : Mixers and Blenders

Mixing Oxidizing

SPECIAL DESIGNED PULVERIZER

Categories : Material Processing Machines

Suitble materials: HDPE, LDPE, flexible/rigid PVC, polypropylene, polystyrene, polyamide, polyester, copolymers, fluoropolymers and synthetic rubber etc. Pulverized Range: 0.1mm to 2mm quality pow...

Round-Barrel Mixer CL-Z

Categories : Mixers and Blenders

Suitable for many kinds of material. It is specially equipped with high speed motor & diffusion tool, which can mix material more evenly in a short time. No residual heat and no damage to the quali...

CL-F-PE Agglomerator

Categories : Material Processing Machines

This agglomerator is specially designed for recycled materials regeneration, for materials such as plastic bags recycled materials etc.

Horizontal Cooling Mixer CL-HV

Categories : Mixers and Blenders

Vertical installation of motor & reducer saves space; Adopts fixed rev. Speed AC motor drive suitable for general material mixing. Two sides of mechanical seal adopts compressed air purge seal design.

Horizontal Cooling Mixer (U-Type Double Ribbon) CL-K

Categories : Mixers and Blenders

Horizontal Cooling Mixer U-Type Double Ribbon SINGLE RIBBON MIXING BLADE DOUBLE RIBBON MIXING BLADE

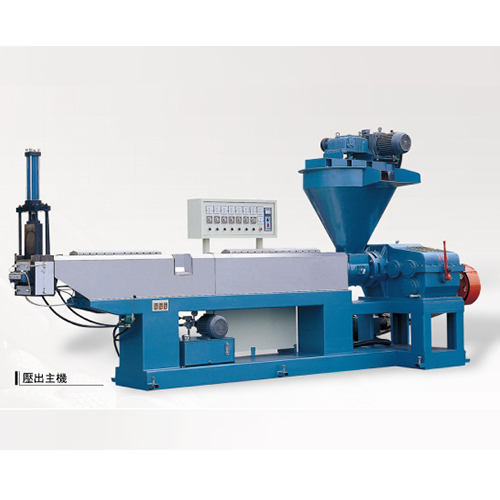

Reclaim Extrusion - RP-MINI-60

Categories : Plastic Pelletizer Machines

Reclaim Extrusion - RP-MINI-60

Rotational Mixer CL-RH

Categories : Mixers and Blenders

Features 3 Layers Ribbon Mixing Blade Layers Ribbon Mixing Blade Low Power Low Speed No Heat Accumulation Big Volume Save Electricity Good Dispersion Minimal Abrasion

Manual / Hydraulic Type Screen Changer | Air Ring & Die Plate or Adaptor | Static Mixer

Categories : Mixers and Blenders

Manual / Hydraulic Type Screen Changer | Air Ring & Die Plate or Adaptor | Static Mixer

RECYCLE PULVERIZER(SCREW CONVEYOR)

Categories : Material Processing Machines

RECYCLE PULVERIZER(SCREW CONVEYOR) This pulverizer is suitable for many materials; for example: plastic pipe, plastic cloth, computer boards, golf balls, etc.

Wrapped Cooling Circulation Mixer

Categories : Mixers and Blenders

Wrapped Cooling Circulation Mixer

Dyeing and Pelletizing Plant

Categories : Plastic Pelletizer Machines

• Model: TY-DB Series • Country of Origin: Taiwan • Applicable resin: PP, PE, ABS, PS. • Specific resin: PC, PET, ACRYLIC, NYLON. • Capacity: 50-1000 kg/hr

High Filler Modified Compound Making Line (CaCo3, TiO2 or Talc)

Categories : Compounding Lines

High Filler Modified Compound Making Line (CaCo3, TiO2 or Talc) Our High Filler Modified Compound Making Line uses our extruder machinery to process different types of compound materials into pelle...

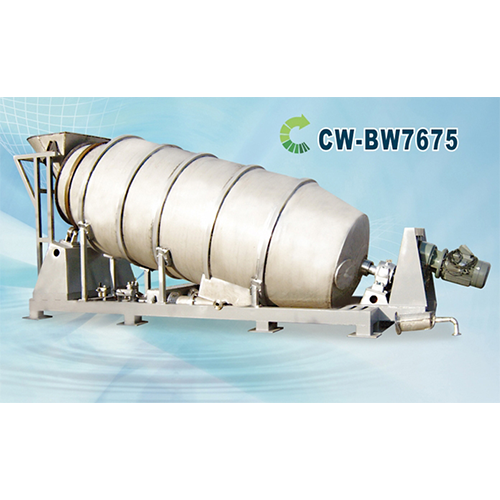

PET Bottle pre-washer BW-7675

Categories : Plastic Washing Line

No need of De-baler because you can feed 2~3 baled PET bottles at same time without tear them apart. The period of time for washing is 45 min. After years of experiences and improvement, this unit ...