Plastic Pelletizing Machine / Pelletizer Extrusion Line

Categories : Plastic Pelletizer Machines

Optional Accessories:(1) Wood flour drier(2) Humidity tester(3) Chiller(4) Water cooling tower(5) Movable electronic balance with portable sewing machine (6) Wood flour grinder

Repet Wood WPC Granule Pelletizer Plant

Categories : Plastic Pelletizer Machines

Indoor & outdoor building material Outdoor furniture

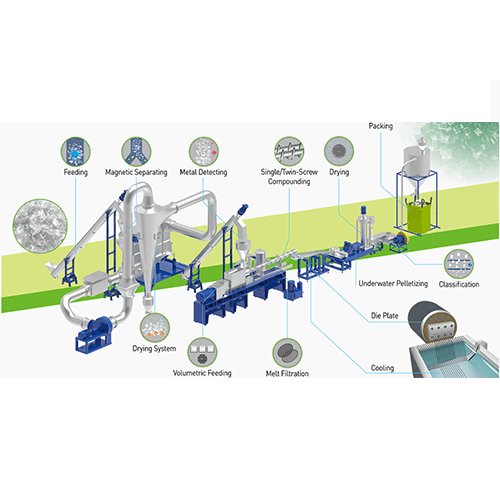

Granulating System: Flow Channel of Plastic Strand Pelletizing System

Categories : Plastic Pelletizer Machines

The plastic strand pelletizing system consists of a die, water-cooling channel, pelletizer, centrifugal hydroextractor and a circulating water-cooling system. Mainly used for plastic materials such as PET、PA、PC etc

Automatic Strand Pelletizing System

Categories : Plastic Pelletizer Machines

Born For Extreme Automation The molten polymer been extruder from the die, fall into automatic water flow. High-pressure water flow from a special designed spray nozzle pulls the strands immediately while cooling at the same time. No more drawing strands before pelletizing. Minimize the lump waste during drawing the strands. GENIUS

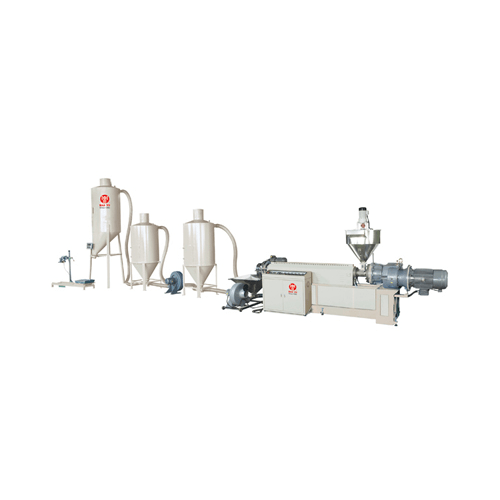

Water-Cooled Type PVC Pelletizer

Categories : Plastic Pelletizer Machines

Water-Cooled Type PVC Pelletizer, wpc pelletizing machine.

Twin-Cone High Speed Pelletizing Machine-Die-Face Cutting

Categories : Compounding Lines

Process Rubber/Plastic mixed material, EVA, TPR, PVC, CaCO3, PVB, PU, TPU compounding, various kinds of masterbatches pelletizing High capacity Low electricity usage Easy to clean and change materials Knead well Die-face cutting Adequate kneading

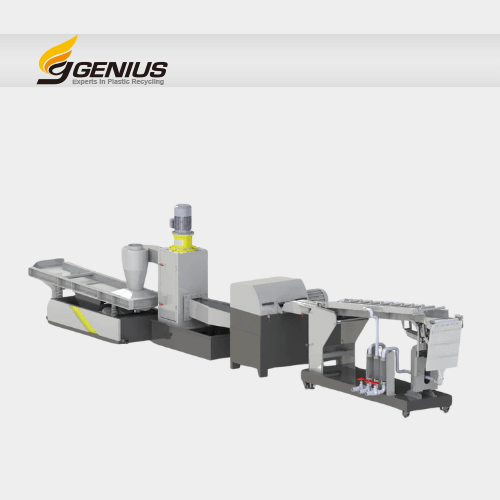

Force Feeding Two Stages Spaghetti Cutting Recycling & Pelletizing Machine

Categories : Plastic Pelletizer Machines

Side feeding barrel is better for storage and steady material input at same time. Main Extruder can extrude the material whose moisture below 7%. Sub extruder conducts second time filtering and ventilating for dirtier materials. Die face cutting frame made in SUS304 to prevent the rust and corrosion. Knives adjustments automaticlly patent design.The knife and die plate always set at 90 degree. No need to adjust frequently. High speed dryer is soundproof with double layer sealing design. The underneath water tank can gather the waste water and filter the impurity. Water circulation pump collects the waste water and the water vapour from pelletization and high speed dryer. The triple layers vibrating screener is easy to clean, disassemble and assemble. Can customize the diameter of the hole. Blower with noiseless design. Big material storage barrel sustains stability during material input. User-friendly machine enables to reach high productivity standards. Product below 7% moisture is suitable for extruding. Applicable to lightweight materials. Low labor cost. Two stages filter makes material more clean

Twin-Cone High Speed Pelletizing Machine-Air Cooling

Categories : Plastic Pelletizer Machines

Twin-Cone High Speed Pelletizing Machine-Air Cooling

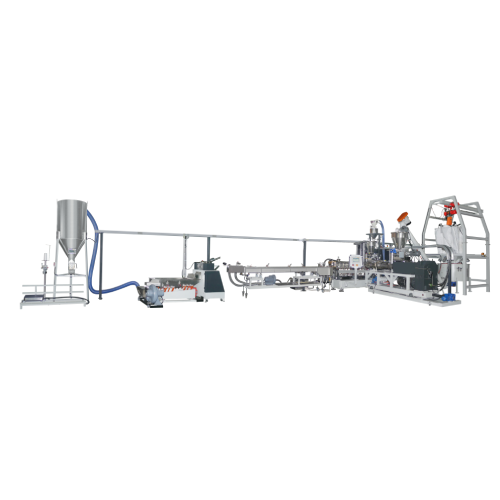

PLASTIC WOOD COMPOSITE MATERIAL PELLETIZER

Categories : Plastic Pelletizer Machines

Our Plastic Wood Composite Material Pelletizer is a state-of-the-art WPC pelletizing machine designed to deliver consistent, high-quality pellet production for wood-plastic composites. This WPC pelletizing machine offers precise temperature control and an optimized extrusion process to ensure uniform pellet size and superior material characteristics. With a robust and efficient design, the pelletizer reduces energy consumption while maximizing output, making it an essential solution for manufacturers looking to enhance productivity and material quality in their WPC pelletizing operations.

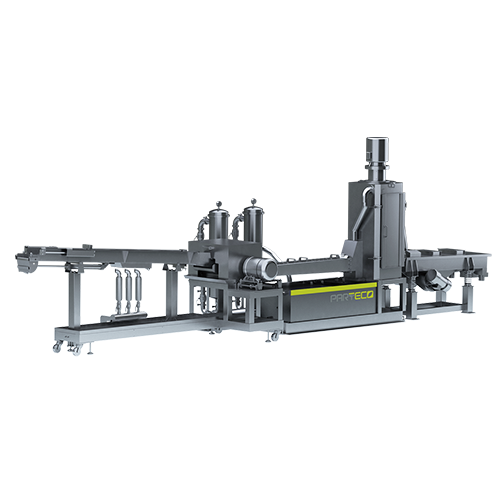

Force Feeding Two Stages Die-Face Cutting Recycling & Pelletizing Machine

Categories : Plastic Pelletizer Machines

High torsion, low-noice; temp. controls stability; double degassing Suitable for a variety of raw materials. Easy to operate; prority transcends traditional model. Low labor cost. Optional equipment- crusher and mixer, enables every batch of material to mix well. Two stages filter makes material more clean