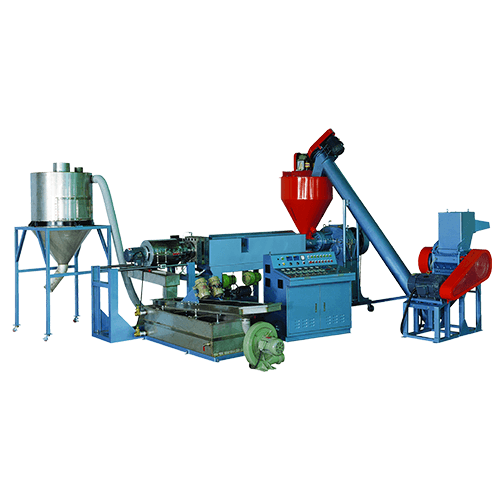

Plastic Waste Recycling Machine

Product Model: YHP Complete Filmblowing Lines for HDPE/LLDPE

Plastic recycling pelletize extrusion equipment

Categories : Plastic Pelletizer Machines

Whole plant equipment includes extruding system,hydraulic plate device for change of materials,stainless steel cooling water tank,cutting machine,which are available for plastic waste articles,pellicle products,mixing color,and making pellet.

IN MOLD DECORATION

Categories : In Mold Labeling Injection Molding Machines

In Mold Decoration (IMD) is a cost effective method of decorating plastic parts. It consists of four steps: Printing, Forming, Trimming and Injection Molding. After a plastic film is silk screen printed with a customer’s design, it is then thermo-formed over a soft tooled mold. Once the plastic decoration is shaped it is trimmed to size. After trimming, the shaped film is placed into an injection mold and a selected mold material is injected behind it forming an integrated bond. IMD offers long lasting decoration with multiple colors and textures. Beyond IMD, membrane switches and/or additional double injection molding can be added to your part or product for extended functionality.

Toggle Outward Injection Molding Machine E Series

Categories : Horizontal Injection Molding Machines

Plastic (toggle outward) injection molding machines are the particular design of toggle mechanism. They allow the application of the dynamic force concentrated on the centre of the moving platen, eliminating deflection and distributing the clamping force evenly over the entire mould surface.

Heat Transfer Film for PC/PS Materials

Categories : Films

Various Plastic Products, CD Barrel, Container、Metal Outer case、House Ware、Stationer, Gift etc. All kinds of PC and PS plastic products can use heat transfer, as long as the surface is smooth and flat, that using special glue, can make design and product can be perfectly combined . Heat transfer film has many function which direct printing doesn't have using heat transfer film and heat transfer machine transfer the elegant design to product to make product becoming high value merchandise. It can enhance quality, decrease cost, and increase profit.

Vertical Plastic and Injection Molding Machine YHL SERIES

Categories : Vertical Injection Molding Machines

- Vertical upright clamping, straight shot structure, simple structure. - The design method of shooting the center shifting element makes the three-sided space more open, and can be applied to the long strip-shaped automobile sealing strip to form a corner or to form a lead product, which makes the forming work easier. - Vertical plastic injection machine, injection system adopts standard and modular design, universal injection molding of various types of inserts, and excellent plastic molding ability. - Vertical rubber injection machine, injection system adopts screw feeding and plunger injection two-stage design, which can adapt to different hardness rubber materials, and rubber injection is stable and accurate. - Optimized design, such as one of the most reliable injection molding equipment for clamping/injection/plasticizing.

Plastic Spring Molding Machine For The Bind Of Detachable Leaves

PVC plastic spring molding machine for the bind of detachable leaves includes extruded system, mold, molding cutter, which can mold one time, save the secondary processing cost. It is available for stationery, such as table calendar and detachable leaves of notebooks.

Total Solution For In Mold Decoration Technology

Categories : In Mold Labeling Injection Molding Machines

• Total Solution For In Mold Decoration Technology. • Environment-friendly plastic decoration process - IMD/FIM/IML. (In-Mold Decoration / Film Insert Molding / In-Mold Labeling) • Product: Housing/casing of mobile phone, mp3/mp4, GPS, Lab-Tab Computer, 3D Labeling of Electric Goods;Automotive Dashboard Meters, Controllers, and Interior Decorative Items; the fancy colored Plastic Body Parts of Motorbike,...etc.

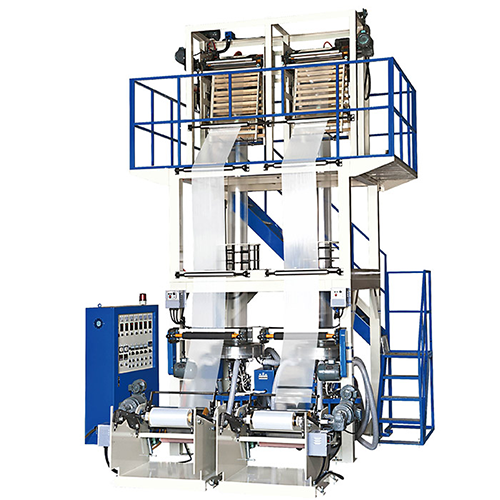

HIGH-SPEED TWO-HEAD MONO-LAYER BLOWN FILM MACHINE

Categories : Blown Film Extruders

This two-head blown film machine line can produce 2 film rolls of the same width at the same time, and the production capacity is thus comparatively higher than models with only one die head. Thanks to the twin-head design, it not only occupies less space but also consumes less energy, which offers an economical solution for producing plastic bags of smaller width.

CONTRACT MOLD MANUFACTURE

Categories : Hot Runner Systems

CONTRACT MOLD MANUFACTURE Yomura offers production molds that will be to customer’s facility or a manufacturing location designated. We manufacture molds for almost every major end market for plastics, like, housewares and delicate medical parts, aerospace parts, automotive parts or tiny parts for consumer electronics. All the molds are built to your specification, including type of steel, runner system, gate type, cavity materials and other features specified. Whenever the molds arrive at your facility, they can fit directly to your injection molding machines and are ready for production. ADVANTAGES Early involvement in design phase Ability to provide accurate and quick mold quote Low cost, quick build and high quality A price fully competitive with major mold makers around the global Long life-cycle and low maintenance Reliable delivery schedules Delivery of bug-free molds and ready for production as soon as arrival Complete integrated design and project management services Adapting the latest technology in design and advanced machine tools Ability to communicate quickly and efficiently, and easy to work with Close to superhighway, allowing for quick travel Service centers and international offices are available in major market countries Joint mold making operations with mold makers in other countries bring Yomura closer to the customers PROCESS FOR CONTRACT MOLD MANUFACTURE Customer supplies 3D CAD file to acquire quote Yomura starts the mold order process based on confirmation Yomura sends the 3D full mold design for your review and approval Yomura starts to build the injection mold upon approval Pilot and short production run after mold completion Sample approval Tooling delivery to location specified

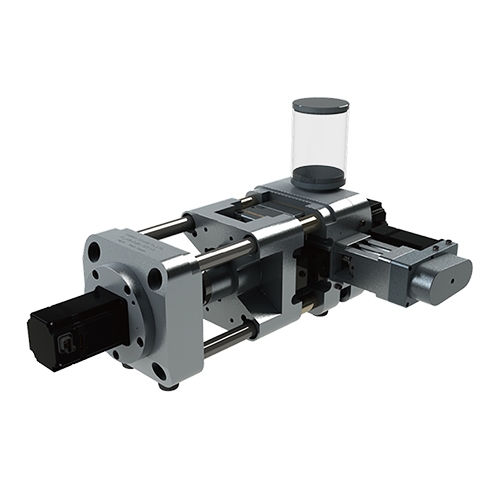

Micro Injection Molding Machines

Categories : Micro Injection Molding Machines

Quick and cost-effective mold solutions. Small order are available. (min. order of 300 shots) Product weight:From 0.001 gram to 8 grams. Product dilensions:From 1mm to 20mm. Materials:Quality can vary from regular grade to engineering grade all kinds of thermoplastics, even high temperature resins. (Ex. PP,PE,ABS,POM,PA,PC,COC,LCP,PEI,PPSU and PEEK.)

Plastic film and bag cutter

Categories : Industrial Knives

Used in many bag making and packaging machines.