Other Auxiliary Equipment

Categories : Control Equipment

Develop control system of other plastic machinery, such as extruder, bottle

INSERT INJECTION MOLD

Categories : Injection Molds

INSERT MOLDING TECHNOLOGY: When a metal, plastic or ceramic part needs to be embedded in plastic to improve product structure it is called Insert Molding. It is a widely used process and one that YOMURA TECHNOLOGIES specializes in. With Insert Molding, a part is placed in a mold cavity then a selected plastic material is injected directly over it resulting is a single part with the insert(s) encapsulated by the material. This process normally uses engineering plastics for improved wear resistance, tensile strength and weight reduction. Insert Molding can be a highly efficient alternative to the assembly of discrete parts using soldering, connectors, fasteners, or adhesives. It also expands plastic capabilities and can reduce final product cost by limiting the amount of costly metal needed to create a part. And importantly, because we can use conventional single shot injection machines for Insert Molding, tooling costs are lower than with a multi-shot processing. Benefits: Reduced assembly and labor costs Because insert molding joins numerous components with thermoplastic, assembly and labor costs are greatly minimized. For example, a single stamping can be overmolded, then perforated to create multiple circuit paths. Reduced size and weight By eliminating fasteners and connectors, and by combining the physical strength of resin and metal inserts, insert molding yields smaller and lighter components. Increased reliability With every part tightly secured in thermoplastic, an insert molded component prevents part loosening, misalignment, improper terminations, and other problems. The thermoplastic resin also provides improved resistance to shock and vibration. Increased design flexibility Designers appreciate the virtually unlimited configurations that insert molding allows. For example, in creating a 3D circuit board, overmolding permits circuitry to move freely through the part, from inside to outside, up walls, down in holes-and the plastic ties it all together. Materials: Engineering plastic or Thermo Plastic Rubber (TPR) inserted with metal frame die casting, plated copper pin, sockets, wire frames, etc. Applications: TPR + Metal Frame(3C Mechanical Parts) ABS + Al. Die Cast (Sports/ Medical) Eng. Plastic + Patting Pin/Eng. Plastic + Wireframe (Connector) Eng. Plastic + Copper Pin/Contact (Precision Electronic Component)

OPTIONAL DEVICES FOR PLASTIC BLOWN FILM

Categories : Assembly Systems

FEATURES Full range of equipment will meet your machine requirement, we also provide machine parts selling individually (Die head and air ring upgrade, screen changer upgrade, winder upgrade etc.).

RAPID PROTOTYPING

Categories : Hot Runner Systems

With the advent of 3D printing, rapid prototyping can now be done quickly and affordably. YOMURA TECHNOLOGIES is equipped with a high end, Digital Light Processor 3D printer built by Carima, a South Korean company with over 30 years of optical manufacturing experience. Unlike Fused Deposition Modeling (FDM) 3D printing which heats a plastic filament then squeezes it through a nozzle to print one layer at a time, DLP uses a special light wave to activate a chemical reaction in a photopolymer resin which then cures into solid 3D object. DLP objects are smoother, more detailed and almost seamless, ideal for professional quality prototypes. 3D PRINTER SPECS Max Build speed: 30mm/hr Resolution: 1920 x 1080 Size: 200 x 112 x 200mm 245 DPI High-end DLP (Digital Light Processing) 12 micron engine enables a very fine prototype Very minimal material waste MATERIALS Acryl: Easy post processing and coloring ABS-like: Semi ABS durability Epoxy: Great durability Rubber-like: Elastic material Lost-Wax: Metal Casting

Heavy-Duty Bag Blown Film Production Line

Categories : Blown Film Extruders

Heavy-duty bags are moisture-proof, high stiffness, impact resistance and puncture resistance. They are used to pack for various heavy-duty goods as like fertilizer, plastic material, grainy, granular and powder-type bulk goods with the form-fill-seal (FFS) machines. The usage of the heavy-duty bags are more and more popular in the market. Specification of KING-PLUS FFS Heavy-duty Sack Blown Film Machine Layers: 1 / 3 / 5 layers Distribution ratio: 1:2:1, 1:3:1, 1:1:2:1:1, 1:2:4:2:1 and so on. FFS film width: Most in 450 ~ 750 mm FFS film thickness: 0.1 ~ 0.18 mm Output: 300~420 kg/hr Option: Online Printer and Internal Embossing Device Achieve one-stop production line - form, print and embossing. - Four-color flexographic printing machine, printing possibility in 4+0, 2+2, 3+1. - Six-color flexographic printing machine, printing possibility in 6+0, 5+1, 4+2, 3+3. Internal embossing device - Raised patterns produced from the inside of bubble to make the surface rough that can enhance the friction to improve the security in piling the sacks.

Primary Packaging–General - Closing - AC-80

Categories : Capping Machines

The container cap closing processor is capable to be applied for both plastic screw caps and ROPP sealing caps in one machine by changing capping system components.

ULTRA LOW ENERGY DRYER

Categories : Dryers and Dehumidifiers For Plastic Materials

The first ULTRA Low Energy Dryer for plastics. Ultra-low kW energy usage - fast ROI and savings for a lifetime. Drying costs so low, it’s almost free Energy efficient unique vacuum drying technology Faster drying, faster start-ups, minimal maintenance

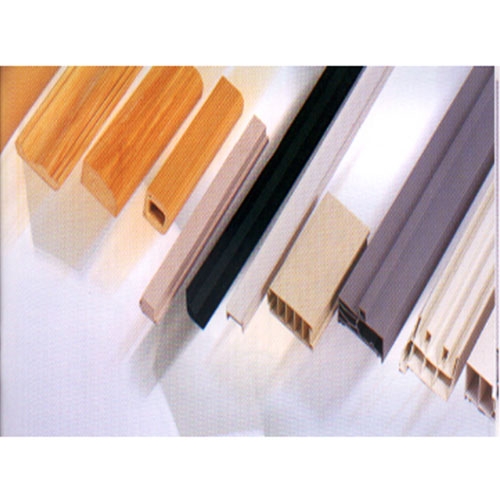

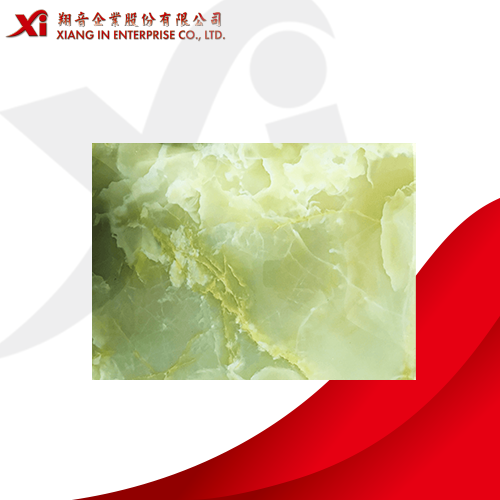

Heat Transfer Film for Glass Materials

Categories : Films

Various Plastic Products, CD Barrel, Container、Metal Outer case、House Ware、Stationer, Gift etc. Adopting Heat transfer film on the glass is absuletly applicable, although the appopriate surface treatment is needed, beforing the printing work be processed. Heat transfer film or thermal film will be perfect solution for PP printingTransfer printed film has many function which direct printing doesn’t have. Using transfer printed film and transfer printed machine transfer the elegant design to product to make product becoming high value merchandise. It can enhance quality, decrease cost, and increase profit.

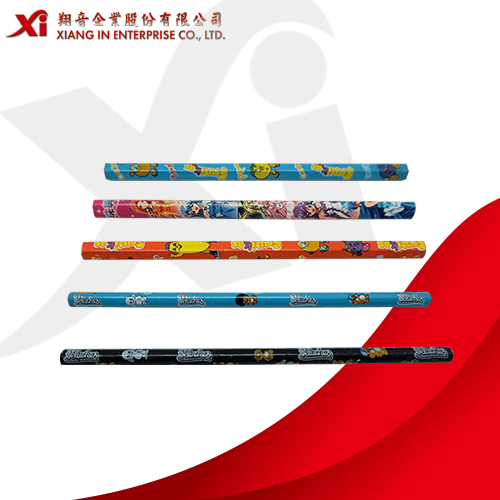

Heat Transfer Film for Stationery

Categories : Films

Various Plastic Products, CD Barrel, Container、Metal Outer case、House Ware、Stationer, Gift etc. Transfer printed film has many function which direct printing doesn’t have. Using transfer printed film and transfer printed machine transfer the elegant design to product to make product becoming high value merchandise. It can enhance quality, decrease cost, and increase profit.

Heat Transfer Film for PP Materials

Categories : Films

All kinds of plastic products made of PP can use heat transfer, as long as the surface is smooth and flat, the design and product can be perfectly combined. Now on the market, many pattern on the paint bucket is use heat transfer technology. Heat transfer film has many function which direct printing doesn’t have. Using heat transfer film and heat transfer machine transfer the elegant design to product to make product becoming high value merchandise. It can enhance quality, decrease cost, and increase profit.

Reel to Reel Injection Molding Machine

Categories : Vertical Injection Molding Machines

Reel to Reel Injection Molding Machine. Fully automated feeding system. A continuous carrier strip fed from rear reel through the front reel (take-up reel) of the injection molding machine, the plastic is molded over the parts on the strip then feed onto the take-up reel.