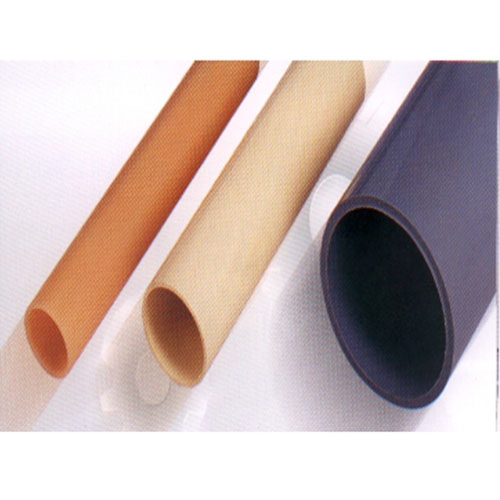

Heat Transfer Film for PP Materials

Categories : Films

All kinds of plastic products made of PP can use heat transfer, as long as the surface is smooth and flat, the design and product can be perfectly combined. Now on the market, many pattern on the paint bucket is use heat transfer technology. Heat transfer film has many function which direct printing doesn’t have. Using heat transfer film and heat transfer machine transfer the elegant design to product to make product becoming high value merchandise. It can enhance quality, decrease cost, and increase profit.

MICRO MOLDING

Categories : Injection Molds

Micro molding is a very specialized art form, which is a kind of tooling design , manufactures small and precision plastic components with polymer-based functional devices, by increasingly demanded in the fields of life science, electronics, medical, photonics, automotive, and aerospace. The tiny-scale molding form of injection molding that entails building a cavity to match the shape of the part you want to make, sort of like the plastic molding that makes Lego bricks. THERE ARE THREE DIFFERENT THINGS TO KEEP IN MIND WITH MICRO MOLDING : Micro means the size of the part. It is the most common definition when dealing with micro molding. Micro features relates to tiny parts on a larger part. As a whole, the part can be big, but its components can be smaller, or micro features. Micro tolerance is how the parts are measured and how close to the needed measurement the part has to be to be considered a good or usable part. When a part is molded, it has to measure within the needed measurement (the tolerance), which could be as small as a thousandth of an inch. Small parts that are simple to make have tolerances that are not as tight and would be considered regular molding. SOME ADVANTAGES OF DESIGN GUIDE IN YOMURA AS : Dimension Aspect ratios around 6:1 (material dependent) Wall thickness : 0.3 mm ( 0.012”) min. for plastic Hole dimension : 0.2mm ( 0.008”) – 0.5mm ( 0.02”) min. Pitch of hole : 0.3 mm ( 0.012”) – 0.50 mm ( 0.02”) min. Tolerance (min) : 0.01 mm ( 0.0004”) – 0.02 mm ( 0.0008”).

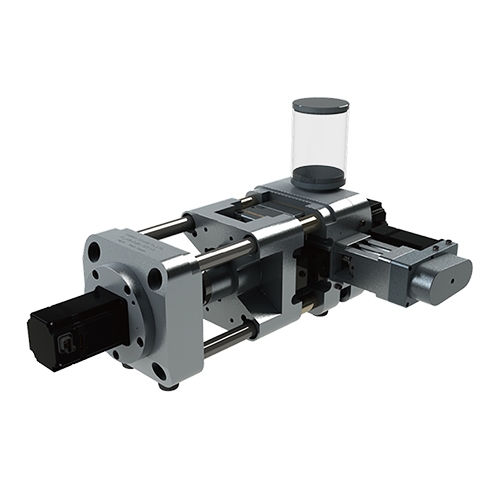

Micro Injection Molding Machines

Categories : Micro Injection Molding Machines

Quick and cost-effective mold solutions. Small order are available. (min. order of 300 shots) Product weight:From 0.001 gram to 8 grams. Product dilensions:From 1mm to 20mm. Materials:Quality can vary from regular grade to engineering grade all kinds of thermoplastics, even high temperature resins. (Ex. PP,PE,ABS,POM,PA,PC,COC,LCP,PEI,PPSU and PEEK.)

Bimetallic Screw

Categories : Screws and Barrels

With a view to meet the ever increasing market demands, present day plastic processors have resorted to the use of plastic raw materials which included all kinds of sophisticated ingredient such as glass fiber additive, carbon fiber, mineral stone powder additive, heat-resisting chemical additive, etc., thereby causing serious abrasion and to the barrel and screw as well as reducing their life span. To meet this challenge, our Co. had several kinds of screw which has shown a remarkable anti-abrasion and anti-corrosion resistance in its practical application. Not only PTA treatment on screw flights, also developed the technique of hardness coating of the entire screw surface, so as to bring more benefits to the processors.

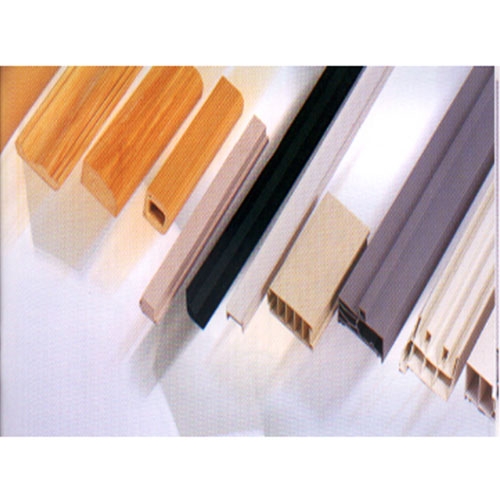

IN MOLD DECORATION

Categories : In Mold Labeling Injection Molding Machines

In Mold Decoration (IMD) is a cost effective method of decorating plastic parts. It consists of four steps: Printing, Forming, Trimming and Injection Molding. After a plastic film is silk screen printed with a customer’s design, it is then thermo-formed over a soft tooled mold. Once the plastic decoration is shaped it is trimmed to size. After trimming, the shaped film is placed into an injection mold and a selected mold material is injected behind it forming an integrated bond. IMD offers long lasting decoration with multiple colors and textures. Beyond IMD, membrane switches and/or additional double injection molding can be added to your part or product for extended functionality.

HDPE Super High Speed Blown Film Machine

Categories : Blown Film Extruders

King-Plus HES Series is designed to produce HDPE plastic film, while LES series for LDPE plastic film. These machines could give you advantages with high-quality, extraordinary mixing performance and high output capacity. With precise machinery design, they could work in efficiency state to realize the achievement of saving energy. HDPE & LDPE film is commonly used to shopping bag, garbage bag, surface protection film and barrier film etc.. There are some auxiliary options as like rotary die seat, auto loader, gusset device, embossing device and auto roll change device and so on, to build a especially-suitable blown film machine for you.

Silicone Double Injection Machine - YD Series

Categories : Silicone Injection Molding Machines

Silicone and plastic double injection system Satisfy two requirements in once.