Single Screw Rubbing Drying Machine

Categories : Plastic Washing Line

With a powerful special designed single screw, it is capable to squeeze wet material. Output Capacity: 500 ~ 1000 kg/hr (different material different output capacity). Can be put into pelletizer for granulating directly. Increase the capacity 60% more. 3% moisture left after drying (used Japan KETT moisture test machine).

RDF-5, Twin Screw Rubbing Drying Machine

Categories : Plastic Washing Line

With a powerful special designed single screw, it is capable to squeeze wet material. Output Capacity: 500 ~ 1000 kg/hr (different material different output capacity). Can be put into pelletizer for granulating directly. Increase the capacity 60% more. 3% moisture left after drying (used Japan KETT moisture test machine).

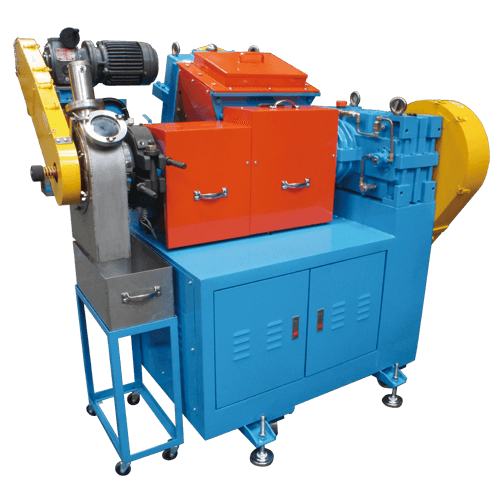

Twin Screw Squeezing Machine (RDF-5)

Categories : Plastic Washing Line

With a special designed twin screw, it is capable to squeeze and form multiple types of material. Output Capacity: 500 ~ 1000 kg/hr (different material different output capacity). Can be put into pelletizer for granulating directly. Increase the capacity 60% more. 3% moisture left after drying (used Japan KETT moisture test machine). RDF-5 is easy to store and saves space.

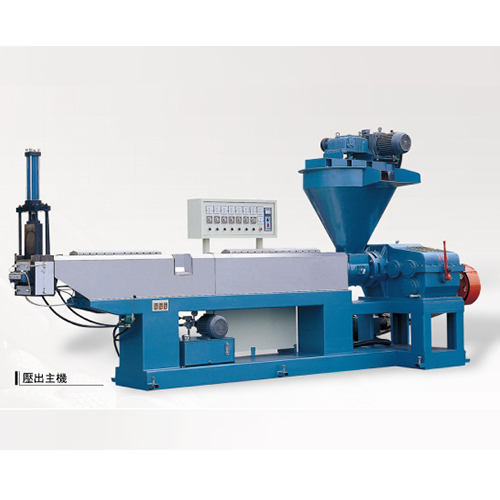

Single Screw Squeezing Drying Machine

Categories : Material Processing Machines

With a special designed screw, it is capable to squeeze wet material. Output Capacity: 500 ~ 1000 kg/hr (different material different output capacity). Can be put into pelletizer for granulating directly. Increase the capacity 60% more. 3% moisture left after drying (used Japan KETT moisture test machine).

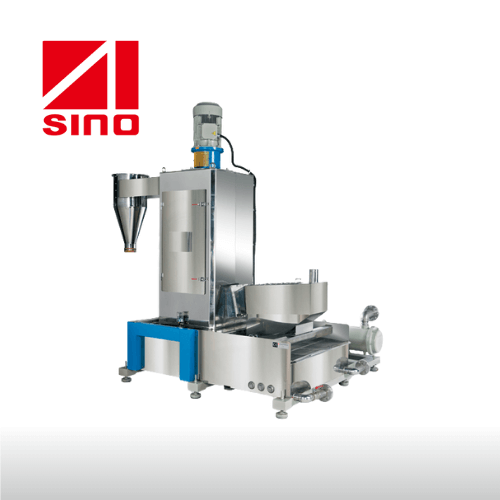

Centrifugal Dryer-PSL

The PSL series centrifugal dryer was developed by Sino-Alloy Machinery as an important and essential accessory for both the PSF series water-ring and PSQ series underwater pelletizers. The PSL series dryers utilize high-speed centrifugal force in combination with forced air flow and evaporation to dry the pellets. Superior performance over vibrating dryers in terms of drying efficiency, throughput, space-saving, and noise level. The PSL series centrifugal dryer can also be a great replacement for that old vibrating dryer.

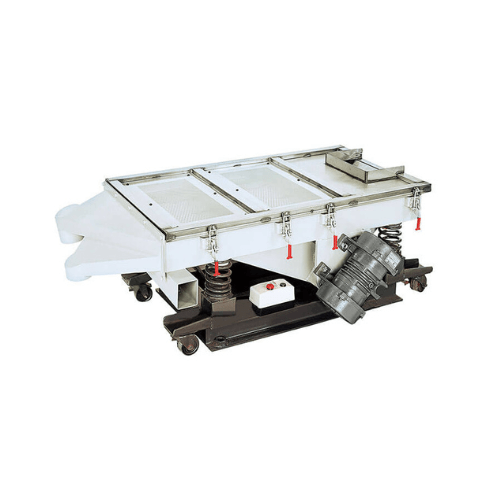

Vibrating Screen

Categories : Separators

The CYKF Vibrating Screen is used for sorting plastic pellets. It divides the pellets discharged from pelletizer. The machine can be combined with our strand pelletizing or underwater pelletizing extrusion lines.

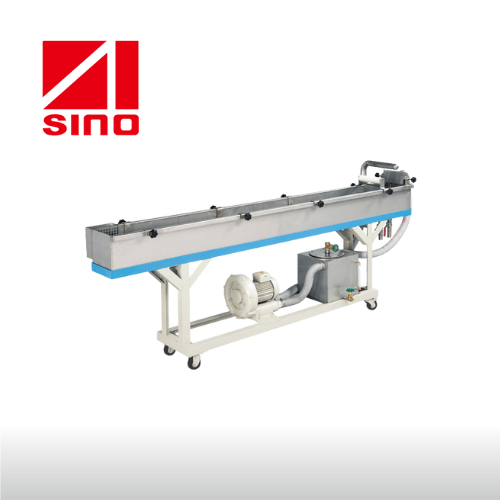

Water Cooling Bath-PSK

The PSK series cooling bath was developed by Sino-Alloy Machinery as an important and essential accessory for the strand pelletizing process. The extruded plastic strand is passed through the cooling bath then dried by an air blade and low pressure vacuum before entering the strand pelletizer to be cut to size. It has a simple design which can be customized with chillers or heaters depending on the production needs.

Strand Pelletizer

Categories : Plastic Pelletizer Machines

CYKF self-made strand pelletizers are able to handle most kinds of plastics. The strand pelletizers can cut cylindrical plastic strands into even pellets. In order to response different demands on capacity, CYKF develops 5 models for choice. The modular design can easily fit into any existing production lines to immediately support production. Moreover, we provide the complete product range for strand pelletizer, including water tank, strand dryer, vibrating screen and storage tank. The comprehensive service saves time as well as solves troubles on system integration. All equipment is designed and manufactured by CYKF which guarantees the quality of the products. Currently the CYKF strand pelletizers are widely used in polymer, recycling, chemical, electronics, automobile, and food industries, etc. The stable operating performance and long service life earns good reputation from customers, and the excellent features have already made contributions to lots of industries in the world.

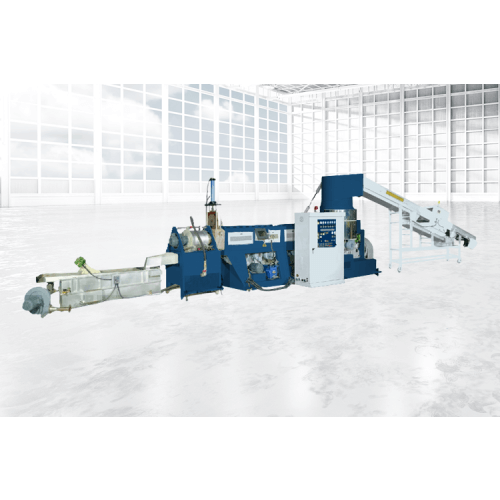

3-in-1 Plastic Recycling and Pelletizing Machine

Categories : Plastic Pelletizer Machines

The machine consists conveyor, shredding drum, extruder and pelletizer to integrate the production to minimize working time and save the manpower.

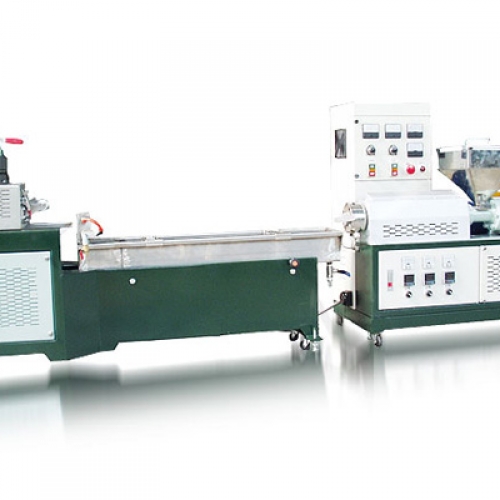

LAB EXTRUDER-Pelletizer (PR-50)

Categories : Plastic Pelletizer Machines

One of our main products, this can be attached to numerous different machinery lines, including pelletizing lines, master batch machines and compounding machines. Our machinery can process many different kinds of pellets including: (EVA, HDPE, PVC, PE, CaCo3 Sulfur etc) The PR-series is a combination of twin-screw feeder and extruder, which is able to process a round mass of raw materials produced by a banbury mixer. This twin-screw design feeds raw materials so stably that it’d decrease the risk of material supply shortage, and further, it’d increase both the yield rate and product quality. Besides, it would create a stable production line by reducing your labor cost and time with this unique design.

Dyeing and Pelletizing Plant Color Testing

Categories : Plastic Pelletizer Machines

• Model: TY-DB Series • Country of Origin: Taiwan • Applicable resin: PP, PE, ABS, PS. • Specific resin: PC, PET, ACRYLIC, NYLON. • Capacity: 3-10 kg/hr