Single-Valve Dynamic Pressure Controller

Categories : Indicators and Sensors

Product Serial: QKL-UHR/QKL-B1HF

Stepper-Controlled Proportional Valve 0-1200L/min

Categories : Separators

Product Serial: FC-1000+PM-1000 Proportional Flow Control Valve consists of PM series driver and FC series proportional flow valve. With an input signal either through analogue or digital, the needle inside the proportional valve moves proportionally to the signal. This series is able to control the flow rate of air and liquid with high resolution, high accuracy, and high repeatability. It is developed for industries that require a high degree of adjustment in flow rate. Series PM driver provides series FC valve with the required power and control signal (step and direction). It controls the step of a bipolar stepper motor with an analogue signal (0-10 VDC/4-20mA/RS485 Modbus).

2500 High Performance Controller

Categories : Indicators and Sensors

Double configurable input for strain gauge / potentiometer / linear signal / TC / RTD Two auxiliary analog inputs Differential measurement High precision: 0.1 % f.s. ± 1 digit Automatic calibration for 6-wire strain gauge Transmitter power supply and strain gauge probe power supply PID controls with 8 sets of selectable parameters 4 configurable alarms, failsafe function Up to 3 isolated analog outputs for control and retransmission 4 digital inputs 4 relay outputs with configurable function Expansion with 4 configurable digital inputs and/or outputs Serial communication interface: - RS485/RS 232 MODBUS RTU protocol (optional) - Profibus DP Slave (optional) Front panel with three 5-digit displays and two bar graphs

Proofing Machines FCM-1300

Categories : Slitters and Rewinders

Applications of FCM-1300 Proofing and sampling for engravers & packaging printers Functions of FCM-1300 Check cylinder engraving quality including the accuracy of text, colors and ink standards. Production press simulation for samples with different colors offers variety for customers. Benefits of FCM-1300 One man operation. 10 minute proofing. Reduces ink and material use. Maximizes production press time. Use production inks and materials. Features of FCM-1300 1. Machanical position on printing roller In combination with inductive proximity switch and mechanical headstock can make sure the printing roller will return to exact position before every proofing. 2. High solution cameras and video registration system With a high solution camera and an electronically generated dual cross on the screen which 16 times magnifies the arrow on every cylinder can eliminate parallax error. 3. Adjustable doctor blade device Consists of 2 doctor blade to intense the hardness. Adjustable angles and pressure accommodates variable patterns of the cylinder. 4. Shaft-less air chuck Allows easy and safe loading of a cylinder and wash-off by one operator. It can be suttle adjusted to accommodate different width of the cylinder. 5. Adjustable cylinder deck Easy and safe operation for loading the cylinder by pneumatically adjusting the deck upward and downward. 6. Superduper printing roller (1)Smooth, rustproof, and heavy-duty printing roller through chromium-electroplated and grinding process. (2)Bouncy compressible blanket, closely dovetailed with printing roller, can easily be replaced when it is blot and spoiled. (3)The proofing length is up to 2500mm. Depending on the size of cylinders, it can print at least 2 copies of samples in every proofing. 7. Powerful vector motor The printing roller is driven by an powerful 7.5 HP vector motor. 8. Adjustable proofing speed Accommodating different material and ink quality, the proofing speed can be adjusted from 20 to 90 m/min. 9. Linear guide way All of the sliders applied to air chuck and cylinder adopt linear guide ways. With height position exactitude, the device will not facilely glide on linear movement.

Automatic Feeding Precision Cutting Machine (roll-to-roll) SCM-65-SP

Categories : Foaming Machinery

Designed in high-precisio construction, this machine can be used to perform full-cut & half-cut fabrication tasks.

Automatic Feeding Precision Cutting Machine SCM-60

Categories : Foaming Machinery

Designed in high-precisio construction, this machine can be used to perform full-cut & half-cut fabrication tasks.

Automatic Feeding Precision Cutting Machine SCM-65

Categories : Foaming Machinery

Designed in high-precisio construction, this machine can be used to perform full-cut & half-cut fabrication tasks.

High-accuracy Multi-function Hydraulic Cutting Machine SC-650

Categories : Foaming Machinery

The machine body has been machined for several finishing processes in creating low-profile variable high-rigid machine body.

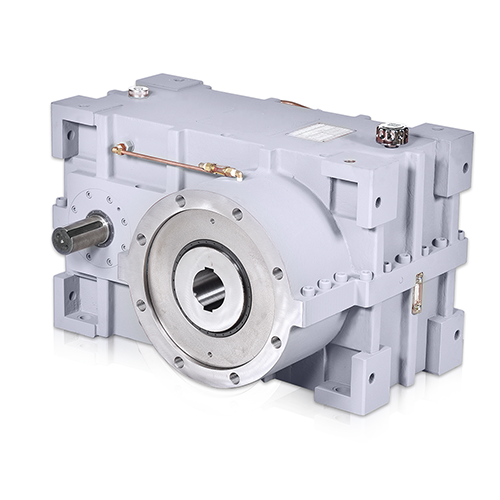

Stepless Gear Box with Selectable Input/Output Orientation

Categories : Gearboxes

Equipped with precise gearbox newly developed by ourselves,our extruder features improved performance, high efficiency, and extended service life. We also produce and export various kinds of extruding machine parts and components. Contact us for more information.

Rubber Vacuum Compression Molding Machine

Categories : Compression Molding Machines

Rubber products compression molding machine which has high steel column style mechanism with high precision of parallelism. Adjustable daylight and various customzied demolding ways accommodates different height of molds.

AUTOMATIC FEEDING PRECISION CUTTING MACHINE (ROLL-TO-ROLL) APL-500SP

Categories : Foaming Machinery

Designed in high-precisio construction, this machine can be used to perform full-cut & half-cut fabrication tasks. Up/down punching travel uses four high-rigidity guide poles, with liner rail designed for the feeding mechanism. Automatic cutter adjusting mechanism can perform automatic adjustment according to the desired setting, providing 0.01mm accuracy. High speed mult-axis servo control system, increases efficiency. High quality CCD positioning system, fast operation and high accuracy. Powerful, high rigidity cam drive system for high stability. The machine is equipped with protection device to ensure the safety of the operator and the machine. (with CE optional)

HIGH PRECISION HYDRAULIC CUTTING PRESS CSS-607

Categories : Foaming Machinery

The Structure Of Press Body Is Made By Special Steel Shaped Materials That Features Pressure-Resistant Function To Maintain A Permanent Plane, With Its Integrated Shaping Of Punch And Slide To Fully Shows A High Resistance Of Wear And Tear, Excellent Strength And Stable Pressing That Would Help Prolong The Service Life Of The Mold. The Cutting Tool Can Be Used With Laser Cutter For Either Pressing Or Die Pressing, Thus Making Product No Burrs And Enabling Clear Angles. The Blowing Device Can Be Worked Further With Mechanical Action, One Punch And One Blowing Subsequently To Absorb Automatically The Well-Cut Finished-Goods That Makes An Easy Access And Safe To Take Feeds, Along With An Installation Of The Almighty Grooved Base Plate, The Mold Locking Is Convenient And Rapid. With A Device Of Fixed-Point Type Pedal Switch, It Shows Up A Mature Technologic Design For Industrial Use. With Its Semi-Automatic Knife Mold Design, It Enables Operators An Easy And Safe Operation.