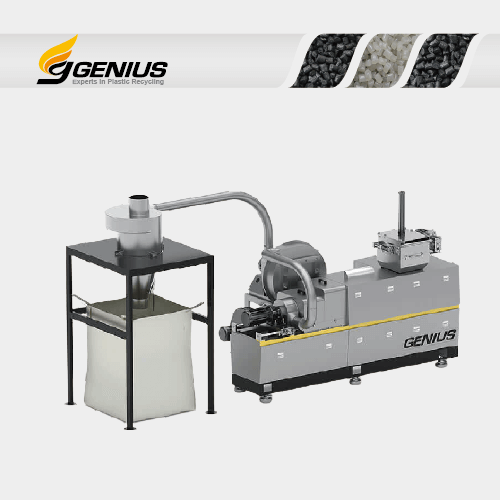

KRS Air Cooling Recycling Machine

Categories : Plastic Pelletizer Machines

In the process of manufacturing plastic film, recycling is a vital step. In order to save production costs and create more profit, many manufacturers are recycling their in-house materials. The KRS Air Cooling Recycling Machine is specifically designed to process edge-trimmed recycling from PE bag production line. It can recycle light printed plastic films into homogenous and high-quality pellets. In most cases, 100% of the recycled pellets produced by KRS can be reused in products production line.

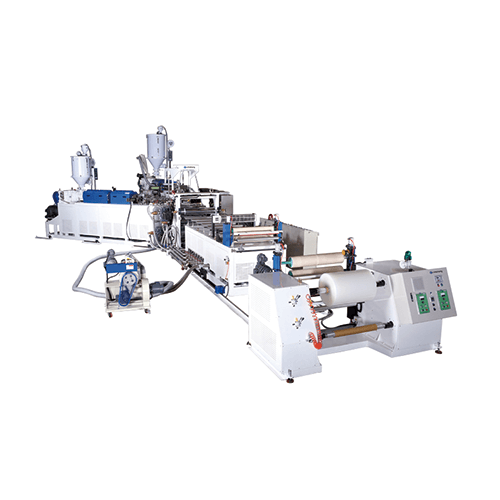

Sheet Extrusion Line

Categories : Film and Sheet Extrusion Lines

Mono-layer and Multi-layer Sheet Extrusion System for up to 5 layers Versatile and reliable downstream equipment Complete Sheet Extrusion Line with extruders 55-200 mm Processing Capabilities: ABS, PE, PP, PS, PET, PC, PMMA, and other thermoplastic materials.

Success Stories- PET Blow Molding Machines – Congo

Categories : Horizontal Blow Molding Machines

The mission for Trip to Congo

Strand Pelletizing System

Categories : Plastic Pelletizer Machines

Minimize The Powder Waste Suitable for higher MI or sticky materials. Production line is equipped with high-precision pellets cutter and specially designed vibrating screener.

7 Layer Die Head

Categories : Extrusion Dies / Dies Heads

Die head can be manufactured to meet customer’s specific extruding capacity and bag width. Precision construction throughout assures maximum uniformity of film thickness. Die head is tempered and annealed to relieve stress, featuring deformation-free and outstanding stability. Easy to wash for convenient and fast color-change. 2~3 points temperature control. Die lip sizes are made according to customer’s requirement. HSIN LONG

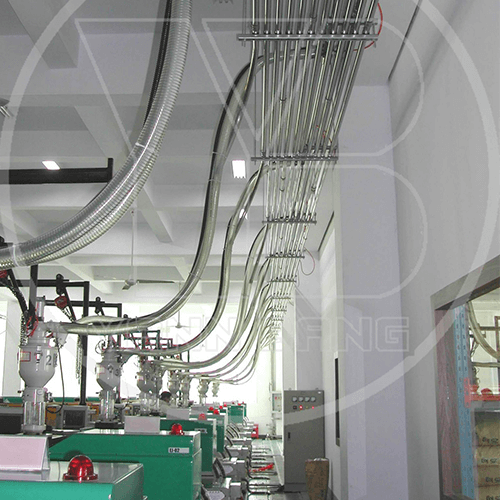

Central Material Conveying System

Categories : Loading and Conveying Machines

Our central vaccum conveying system also called centralized pneumatic supply system. It can be completely customized to your plastics processing to fullfill the target of continuous operation without downtimes. Central Material Conveying System A central conveying system can control 30 sets of molding machines at the same time and return on your investment in 2-3 years. 1. Better company image 2. Greater productivity 3. Lower cost 4. Better energy efficiency 5. Less material waste and pollution during the conveying process 6. Better working environment 7. Less noise due to the separation of the blowers from the working place

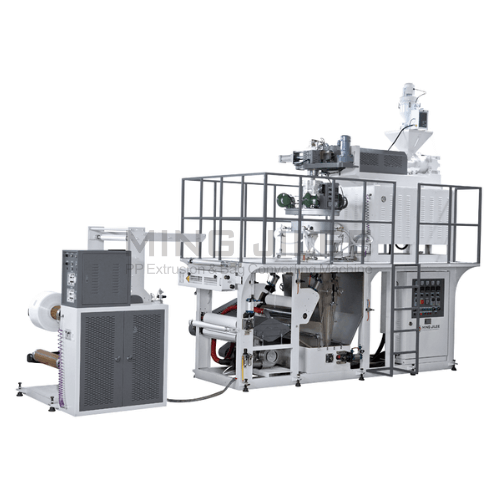

HIGH SPEED BLOWN FILM MACHINE

Categories : Blown Film Extruders

MONO-LAYER HDPE/LDPE/MLDPE/PP BLOWN FILM MACHINE

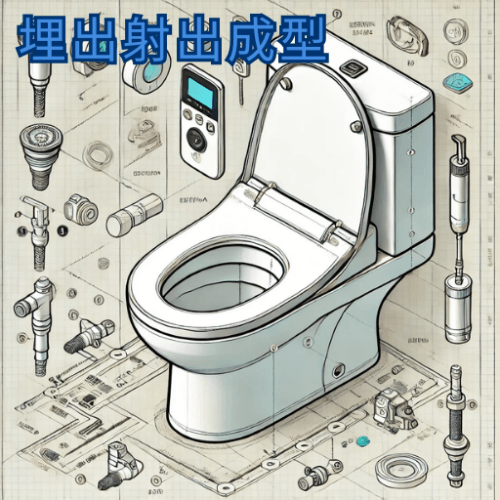

Toilet Seat Related Parts

We specialize in manufacturing toilet seat-related parts, suitable for various toilet seat models, including standard, soft-closing, and automatic-opening types. Our product range includes hinges, soft-close dampers, mounting brackets, buffers, and locking rings, ensuring smooth operation and enhanced user experience. We use high-quality plastic materials such as PP, ABS, POM, and Nylon, offering excellent durability, impact resistance, and moisture protection, guaranteeing long-term performance stability.

Accumulator Head Blow Moulding Machine for L Ring Drum & Open Top Drum

Categories : Blow Molding Machines by Layers

Accumulator Head Blow Moulding Machine for L Ring Drum & Open Top Drum

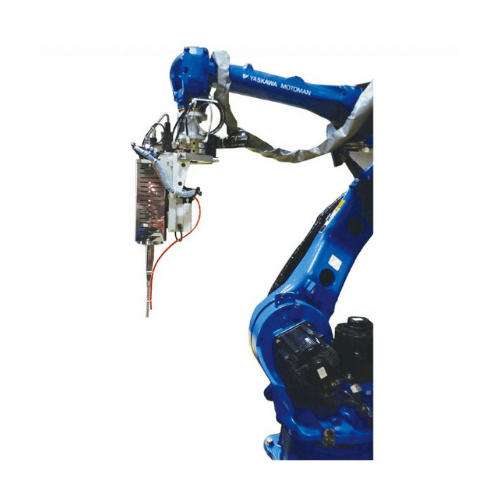

Ultrasonic welding module of Automation KWD(IGBT)

Automatic tuning (Frequency control) Resonance frequency compensation during welding cycle. Full bridge IGBT module are used in the generator to improve durability PWM(Plus Width Modulation) amplitude control PWM controls amplitude during start-up to prevent horn damage due to high voltage starts. 8 selective start-up settings for ultrasonic activation to match various requirements of horn's design Protection against Ultrasonic frequency offset & high voltage overload. Automatic frequency self-checking at start-up Frequency compensation as horn's working temperature variation LCD displays the frequency and percentage of amplitude Two kind of welding mold, Time control mold & trigger mold Simple operation, 7" touch panel , abnormal information text display

5-Layer Co-Extrusion Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

Extruder 5-Layer PE Group/Recycled/PA/EVOH 5-Layer Co-Extrusion Blown Film Machine 5-LAYER CO-EXTRUSION BLOW