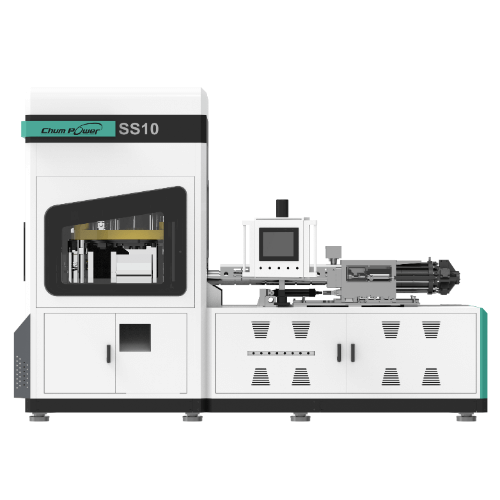

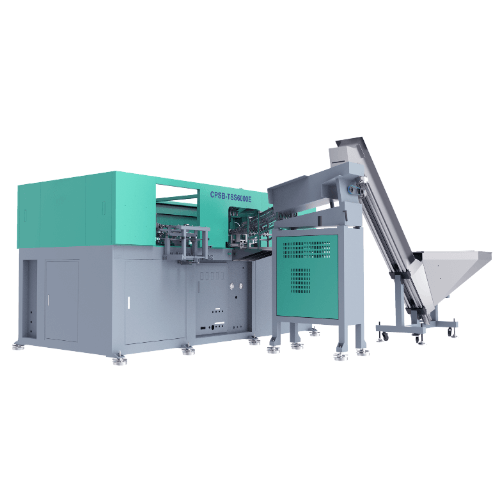

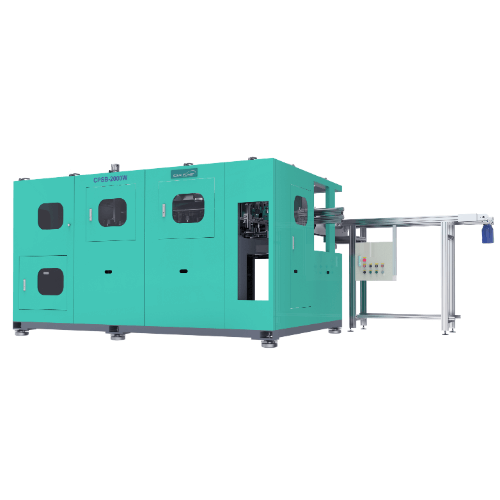

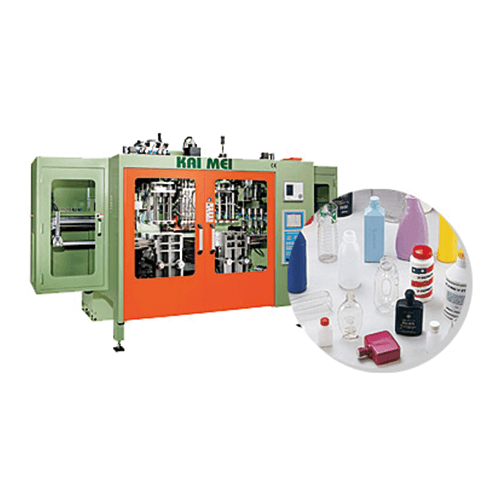

Classification : Injection Blow Molding Machine

Country: Taiwan

Phone: 886-4-23396828

Fax: 886-4-23394679

Contact Person: Sanni Yang

Features

- HMI Touch Screen(Fuji-Japan), Incorporating with PLC system(Omron-Japan) for easy maintenance.

- The machine provides fast molding performance without scrap or connecting lines on bottle bottom or side.

- Maximum uniformity of bottle weight, thickness and volume.

- Extremely smooth and elegant bottle surface is ideal for high-quality and high-price packaging.

- This high production machine is capable of producing bottles in multiple cavities at one time.

- Suitable for various materials, such as PE, PP, PS, PC, etc., for producing various types of bottles.

- Multiple-stage injection.

Application

Roll-On Bottle |

Cosmetic / Personal care |

Cosmetic / Personal care |

Laboratories |

|

Eye Drop Bottle |

Medical Supplies |

Baby Bottles |

|

- Three Station Type

- Production Volume:2ml~3,000 ml

- Multi cavities: 1~16 cavities

- Specialize for the PE/PP/PC/PS/

- Driven Model: Hybrid servo motor drive system/ High performance hydraluic power saving system/Close loop proportional valve

| MODEL | UNIT |

PK-30IB |

PK-55IB |

||||

|---|---|---|---|---|---|---|---|

| INJECTION UNIT | |||||||

| Screw Diameter | mm | ∅32 | ∅40 | ∅45 | ∅50 | ∅55 | ∅60 |

| L / D | 22:1 | 22:1 | 22:1 | 22:1 | 22:1 | 22:1 | |

| Screw-speed Range | RPM | 0-120 | 0-120 | 0-120 | 0-120 | 0-120 | 0-120 |

| Screw Stroke | mm | 150 | 150 | 200 | 250 | 250 | 250 |

| Max. Shot-weight | g | 65 | 100 | 170 | 265 | 320 | 380 |

| MOLD CLAMPING UNIT (INJECTION UNIT) | |||||||

| Injection Mold Opening Stroke | mm | 115 | 135 | ||||

| Injection Mold Clamping Force | ton | 30 | 55 | ||||

| Trigger Bar Length | mm | 335 | 735 | ||||

| Max Swing Radius | mm | 410 | 570 | ||||

| MOLD CLAMPING UNIT (BLOWING UNIT) | |||||||

| Blow Mold Opening Stroke | mm | 115 | 135 | ||||

| Blow Mold Clamping Force | ton | 5 | 10 | ||||

| POWER SYSTEM | |||||||

| Pump Motor | HP | 25 | 40 | ||||

| Pump Pressure | kg/cm² | 130 | 130 | ||||

| Heating Capacity | kw | 11 | 14 | ||||

| Heating Zone | point | 6 | 8 | ||||

| Air Requirement (Approx.) | m/hr | 30 | 30 | ||||

| Air Pressure | bar | 10 | 10 | ||||

| Oil Tank Capacity | L | 350 | 550 | ||||

| Total Power Consumption | kw | 30 | 44 | ||||

| Machine Dimension | M | 3.2x2.0x2.2 | 4.7x2.1x2.5 | ||||

| Machine Weight | ton | 5 | 10 | ||||

| Packing Size | M | 3.5x2.2x2.2 | 4.9x2.2x2.2 | ||||

| Machine Meas't | M³ | 20 | 34 | ||||

* All specifications and designs are subject to change without notice.

PARKER PK-55IB(PE) Injection Blow Molding Machine for 10 cavities

PARKER PK-55IB(PP) Injection Blow Molding Machine for 10 cavities

PARKER Injection Blow Molding Machine PK-30IB(PE)(1x8 cavity)

PARKER Injection Blow Molding Machine PK-55IB(PE)(1x14 cavity)

PARKER Injection Blow Molding Machine PK-55IB(PE/PP)(1x8 cavity)

PARKER Injection Blow Molding Machine PK-55IB(PE)(1x12 cavity)

PARKER Injection Blow Molding Machine PK-30IB(PET)(4 station)

PARKER Injection Blow Molding Machine PK-55IB(PC)(1 cavity)