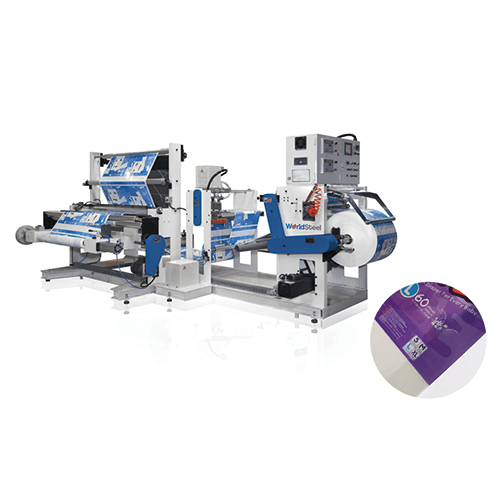

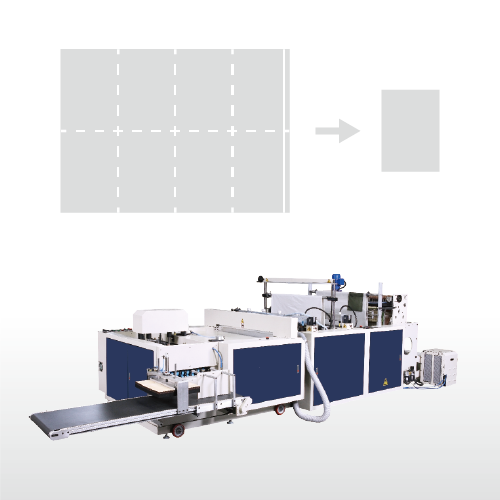

Our folding and hot slitting machine is a high speed, precision processing piece of equipment that fits into any factory or production line in the film conversion industries. If you are looking for a machine to get your film ready for sale or for further conversion. This is the machine for you.

| MODEL | MATERIAL DIAMETER | MATERIAL WIDTH | FOLD SPEED | HEAT SEALING SPEED | ELECTRIC POWER |

| WSF-1200A | MAX. Φ600MM | MAX. 1200 MM | MAX. 190 M/MIN | MAX. 150 M/MIN | 6 KW |

| WSF-1500A | MAX. Φ600MM | MAX. 1500 MM | MAX. 190 M/MIN | MAX. 150 M/MIN | 6 KW |

| MODEL | Machine Dimensions | Machine Weight | Packing Size | Packing Weight |

| WSF-1200A | 3 X 2 X 1.8 M (L X W X H) | 1500 KG | 3.2 X 2.2 X 2 M (L X W X H) | 1800 KG |

| WSF-1500A | 3.5 X 2.2 X 2 M (L X W X H) | 1800 KG | 3.7 X 2.25 X 2.2 M (L X W X H) | 2200 KG |

The quality parts and assembly from World Steel mean that only the best leaves our production facilities. The receiving and discharging motors run in sync also using an automated tension control system, meaning that production is smooth throughout the process. An EPC edge sensor works with the edge trimming device keeping quality consistent and the AC drive motor is able to change speeds seamlessly, as to not interrupt the film conversion process. Heat sealing is performed with a special stainless steel heat sealing knife and this is all controlled via our PLC system working through an LCD screen, so that machine operation is simple and effective.

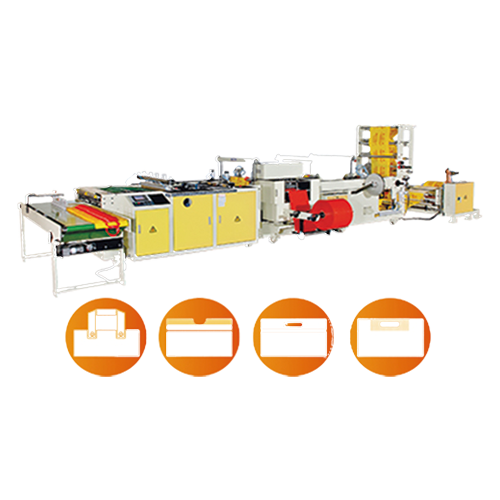

- - Diaper Bags

- - Toilet paper bags

SUITABLE RAW MATERIALS

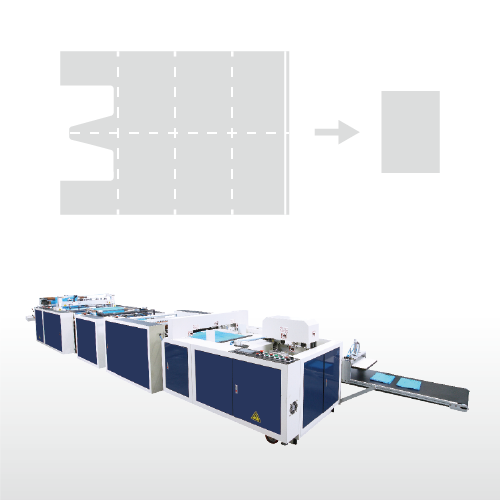

- Materials suitable for this sandwich folding machine are single layer roll films such as PP, BOPP and CPP.