The PVC pipe extruder is a machine that produces PVC pipes by melting and shaping PVC pellets or powder. The extruder consists of a barrel, a screw, a motor, a heating system, and a die. The PVC pellets or powder are fed into the barrel through a hopper, where they are melted and homogenized by the heat generated by the heating system and the rotation of the screw. The molten PVC is then forced through a die that shapes it into a tube of the desired size and thickness.

-

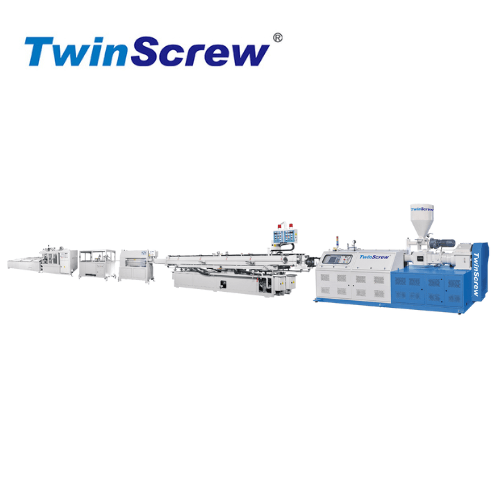

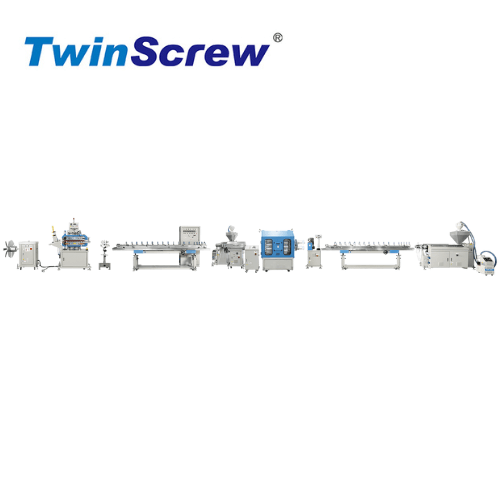

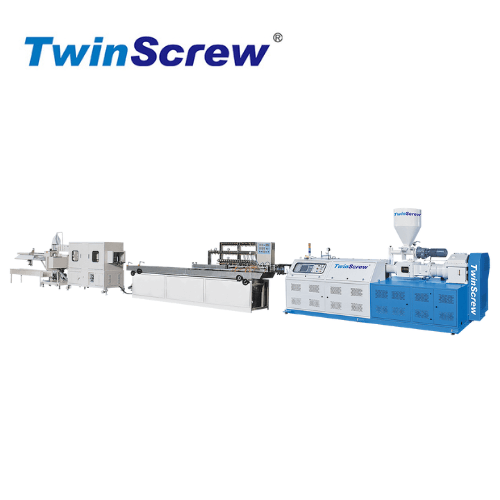

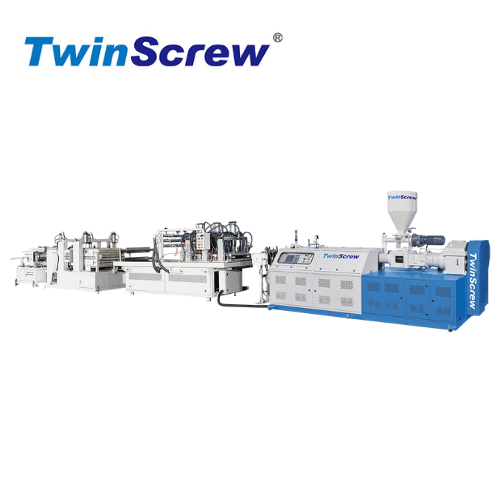

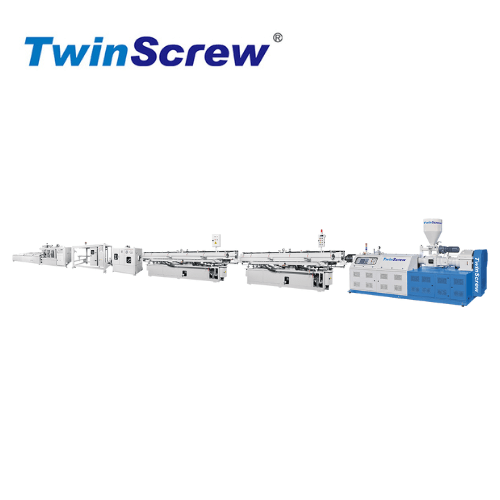

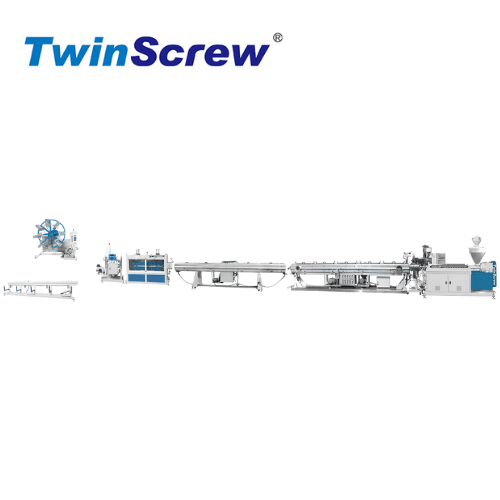

For thirty-five years, TwinScrew has been designing and manufacturing fully computerized lines for pipe extrusion. PVC pipe extrusion line is one of our specialized items.

-

The Parallel twin screw extruder has newly developed for its technologies in UPVC pipe extruded by increasing in the drive torques and innovative solutions to problems in politicizing, screw thermoregulation by self-regulating, sealed water cooling system, vacuum scavenging system and melt pressure control.

-

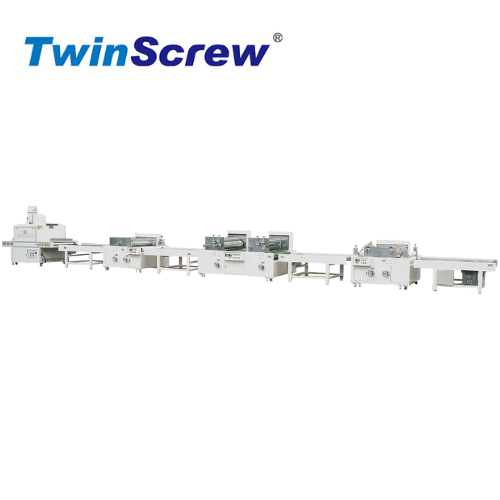

One line equipment includes Main Extruder,Vacuum Spray Cooling Tank,Haul-off Machine,Automatic Traveling Saw, Automatic Belling Machine (or Down Table).

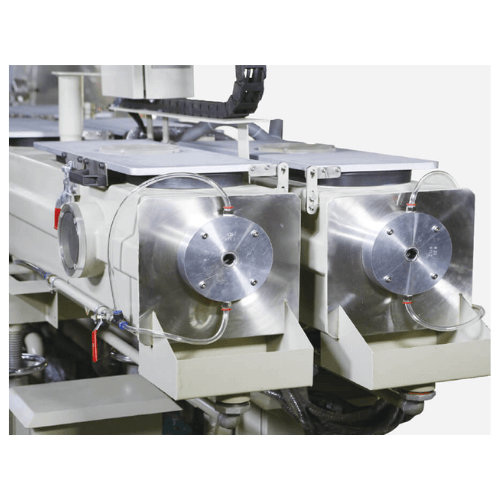

Dies for PVC Pipe Extrusion

The concept of the spider die guarantees outstanding product characteristic for PVC material. The benefits:

- Ideal residence time profile over the whole flow cross-section

- Homogeneous melt distribution

- Simple and reliable handling

Automatic Belling Machine

on line production

Friendly operating

Low maintenance

Non-dust Cutting Machine

Low dust pollution

Easy to recycle the waste

Operation Control System

- Tradition operation-control type

- PC base machine operation

- 1. Two parallel counter-rotating screws for better plasticizing and homogenization.

2.Improved torque-distribution unit with hardened, ground shafts and gear

3.Longer lasting processing unit service life (lower specific drive energy.)

4.Cost reduction.

5.Increased process reliability (modern control technology.)

6.Homogenous

7.User friendly

8.Touch screen.

9.Intelligent temperature control.

10.Easy service and maintenance.

11.Easy synchronization with other machinery.

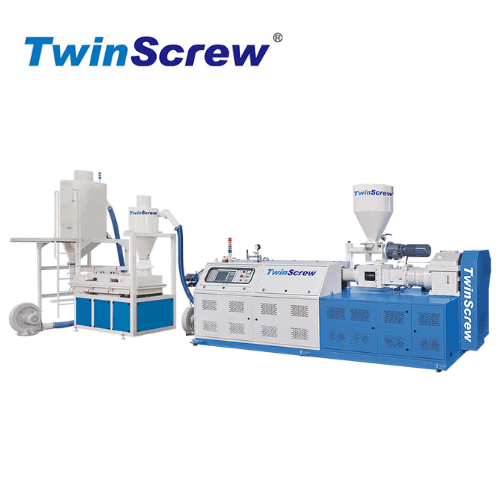

Twin Screw Extruder

- Reduction and torque-distribution unit with hardened, ground shafts and gear.

- Long service life for the processing units due to lower specific drive energy.

- Increased process reliability due to modern control technology

- High safety and Low maintenance frequency.

Pipe diameter from 60 to 630 mm.

|

Model |

Raw Material Applicable |

Suitable Pipe Dia. |

Production Capacity |

|---|---|---|---|

| TSE-75-RP-S | PVC Compounding | 20~110 mm | 150~250 kg/hr |

| TSE-90-RP-S | PVC Compounding | 75~160 mm | 350~450 kg/hr |

| TSE-90-RP-S | PVC Compounding | 110~250 mm | 350~450 kg/hr |

| TSE-110-RP-S | PVC Compounding | 200~450 mm | 500~800 kg/hr |

| TSE-130-RP-S | PVC Compounding | 200~450 mm | 600~1200 kg/hr |

| TSE-130-RP-S | PVC Compounding | 200~630 mm | 600~1200 kg/hr |