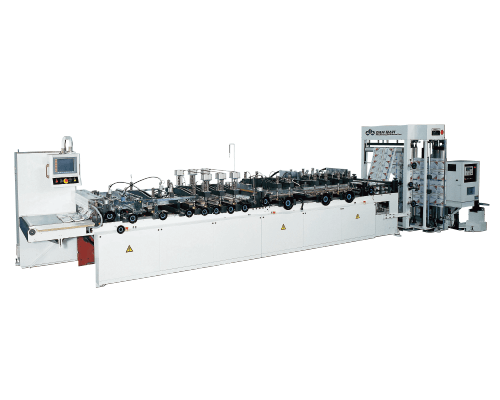

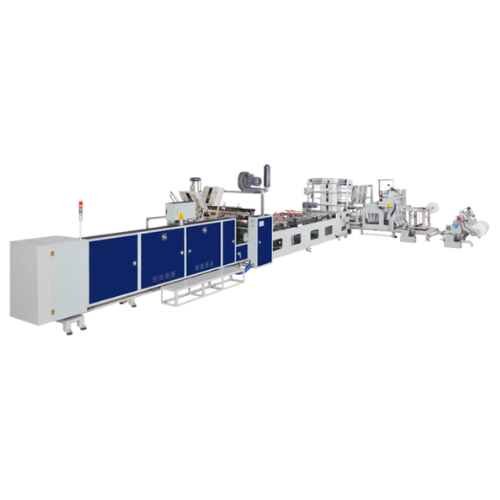

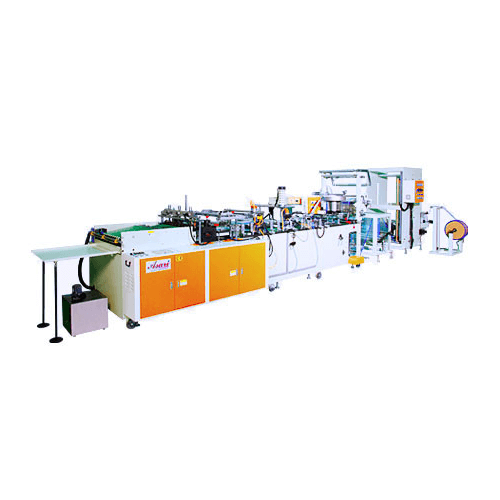

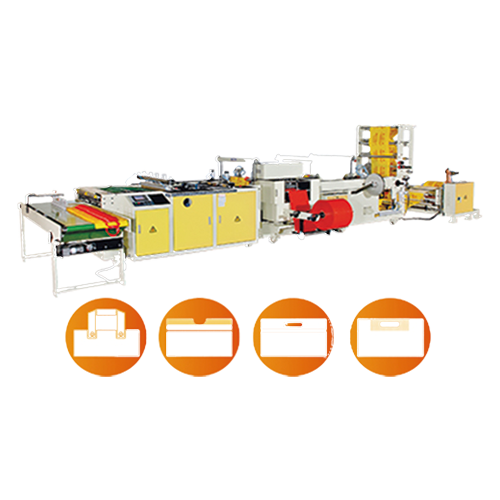

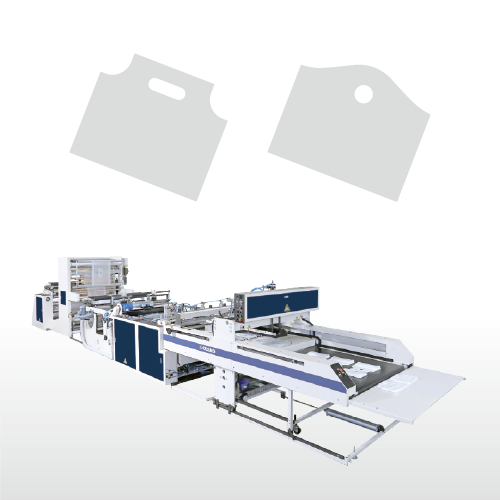

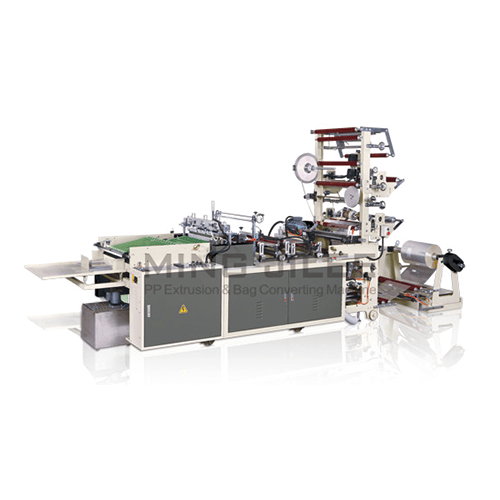

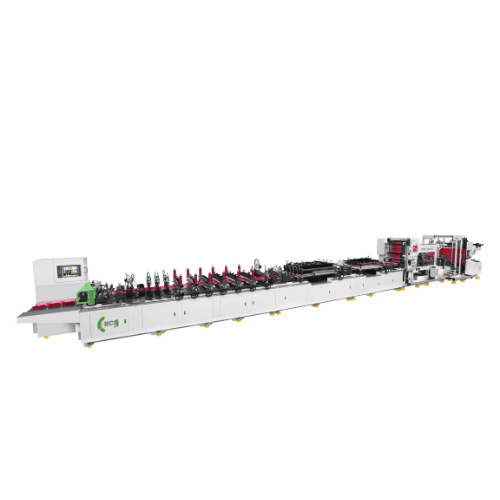

Classification : Bag Making Machine

Country: Taiwan

Phone: 886-4-24832477

Fax: 886-4-24830852

Contact Person: Angela Chi

Application & Materials

- Sealable laminated film, thickness 40-150μ

- Main drive servo motor with driver provide accurate sealing time control, suitable for constant sealing time control system.

- Equipped with two sets of servo motors and drivers, which can raise the production speed and provide accurate bag length control.

- Horizontal type unwind stand / Swing-out/Lift-up type mechanical shaft with 3" adapters makes loading and unloading more convenient.

- Equipped with Automatic Tension Controller (diameter calculating type), provide constant and stable web tension control.

- Equipped with Line/Edge Position Controller (LPC), provide accurate bag sealing and trimming position.

- Upgraded dancer-roller provides stable tension for films before entering the bag making section.

- Four-lanes operation for making 3-side-seal bags.

- Longitudinal double sealing device and cooling devices provides each sealing area could be sealed twice by different sealing temperature. Suitable for high-speed production and ensure the bag sealing quality.

- Equipped with skip operation system, the maximum bag-length could be extended. (skip-times: as request).

- Equipped with automatic lift-up mechanism to lift up the upper sealing stands and bars to avoid overheating the material when the machine stops.

- The design of safety cutter provides extra safety for the operator.

- Equipped with covered bearing, which is unnecessary for lubrication, prolong the parts life and makes maintenance easier, faster and cleaner.

- Maintain a constant sealing time, which may largely reduce test-run scraps. When the machine speed is changed, it is not necessary to adjust temperature of the heater.

- Touch-screen makes operation easier and faster.

- Built-in Sealing Temperature Controller.

- Auto alarm/Stop available for abnormal condition.

- Alarm messages are displayed on the screen.

- Modem interface available for remote maintenance.

- Operation and maintenance procedures and parameters are memorized in the computer control system for easy setup or review.

- Data base for saving 100 sets of working parameters.

- Unwind 3"/6" airshaft.

- Hydraulic loading device (in unwind section)

- 6" air chuck

- Vertical/horizontal 2nd unwind stand

- Various puncher

- Conveyer

- Round corner cutter

- Trim rewinder

- Bottom symmetrical folding stand

ABM-S Series

| Model No. | ABM-54S | ABM-64S | ABM-74S | |

| MAX. PARENT WEB WIDTH | 400~1000 mm | 400~1200 mm | 400~1400 mm | |

| MAX. PARENT WEB DIAMETER | 650/800 mm | 650/800 mm | 650/800 mm | |

| MAX. BAG WIDTH | 500 mm | 600 mm | 700 mm | |

| MAX. BAG LENGTH | 500 mm | 500 mm | 500 mm | |

| MAX. MACHINE SPEED | 180 Cuts/min. | 180 Cuts/min. | 180 Cuts/min. | |

|

INSTALLATION INFORMATION (standard specification) |

NET WEIGHT | 4700kg | 4800kg | 5000kg |

| AREA REQUIRED | L12141xW5229xH1795 | L12462xW5149xH1980 | L12550xW5620xH2195 | |

| POWER | 380V/31KW/65A | 380V/33KW/67A | 380V/35KW/69A | |

| WATER | 15-20℃ | 15-20℃ | 15-20℃ | |

| AIR | 6kg/cm3 | 6kg/cm3 | 6kg/cm3 | |