LATEST UPDATE Subscribe Now

THE LATEST GENERATION OF PET BOTTLE WASHING LINE—ES PROCESS

In response to the PET industry’s quest to increase recycled content by producing high-quality rPET flakes for high-end applications, BoReTech has leveraged its 30 years of experience in recycled polyester industry and developed a total solution for plastic recycling, endeavoring to be a global pioneer in plastic recycling ingenuity.

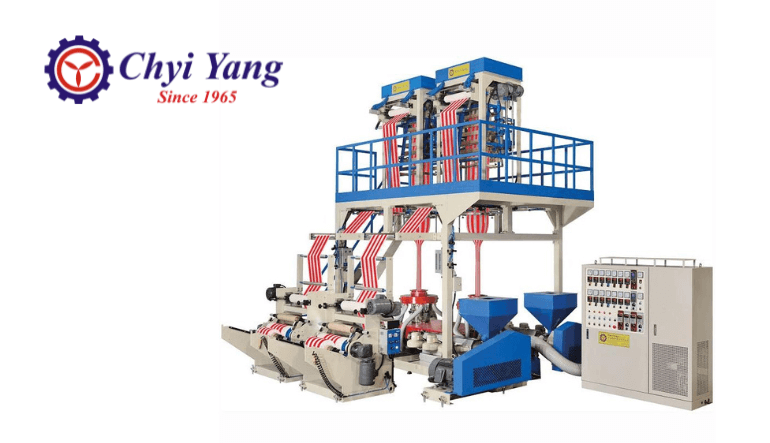

PE Cling Film Produced By CHYI YANG’s Machine Owns 80% of China Market Share

Nowadays, Stretch/Cling film are very common used in daily life, for industrial packing for foods or general goods, and even at home to protect and storage prepared food. There are several materials formulated for its production, being Polyethylene the most convenience for easy processing, because it is suitable for food contact and for easy recycling.

JingDay: A Pioneer in Rubber and Silicone Molding Technology, Forty Years of Expertise Yielding Diverse Applications

Rubber and silicone are no longer unfamiliar materials to most people. With their excellent elasticity, insulation, heat resistance, cold resistance, and outstanding electrical properties, it's easy to spot applications of silicone rubber in daily life. Since its establishment in 1983, JingDay Machinery, with its 40 years of knowledge and technology in rubber and silicone molding, has not only developed various specialized machinery for customers but also covered application fields such as automotive, motorcycles, 3C products, medical, sports products, and golf products.

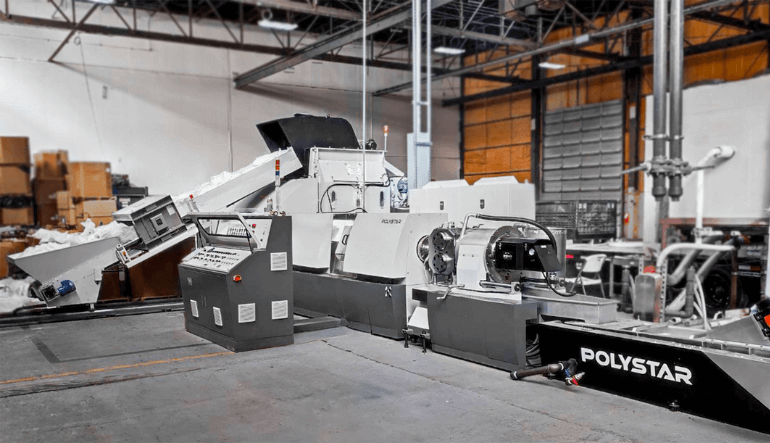

BDB Recycling Leads the Way with POLYSTAR's Innovative Solutions

POLYSTAR is dedicated to creating innovative pelletizing machines that empower businesses to contribute to a more sustainable future. We'd like to highlight one of our valued customers, BDB Recycling, located in Ohio. BDB Recycling shows how our pelletizing machines can revolutionize LDPE/HDPE recycling operations, not only boosting their business but also paving the way for a more circular plastics economy across the US.

Studying Hard at Night School Turns Poor Students into Corporate Directors

Guo Mingyi, chairman of CHYIYANG Industry, has five companies in Taiwan and the mainland. The plastic wrap machinery products are sold in 60 countries in Southeast Asia, mainland China, Central and South America, and Europe.

CHYI YANG Has Sold Over 500 Sets of Blown Film Machines to Latin-America

Chyi Yang showed one set “Two Stripes & Two dies Co-Extrusion Blown Film Machine” in Colombiaplast 2016 exhibition. This machine is equipped with two dies & two extruders to produce two stripes T-shirt bags for market using. This series is very popular because of mainly for following reasons.

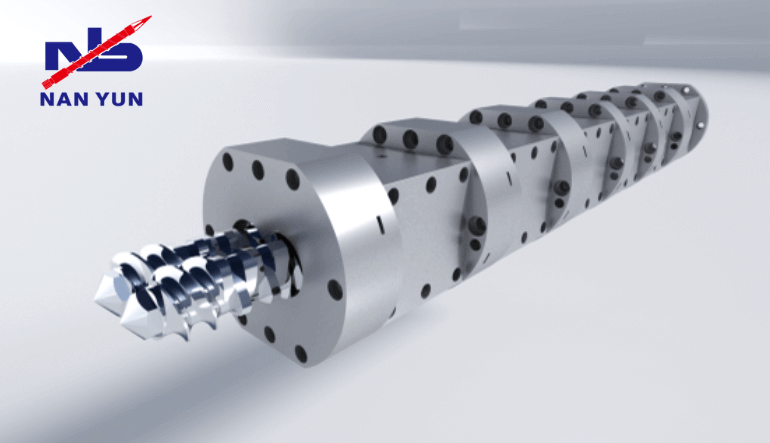

Sustainable Innovation in Extrusion Technology: NAN YUN’s Co-rotating Twin-Screws

Established in 1993, NAN YUN Industrial Co., Ltd. is a leading supplier of essential components for injection molding machines, extruders, and related machinery in the plastic and rubber industry. Our dedicated engineering design team combines exceptional theoretical knowledge with practical expertise, specializing in the meticulous design and production of a wide range of screws and barrels.

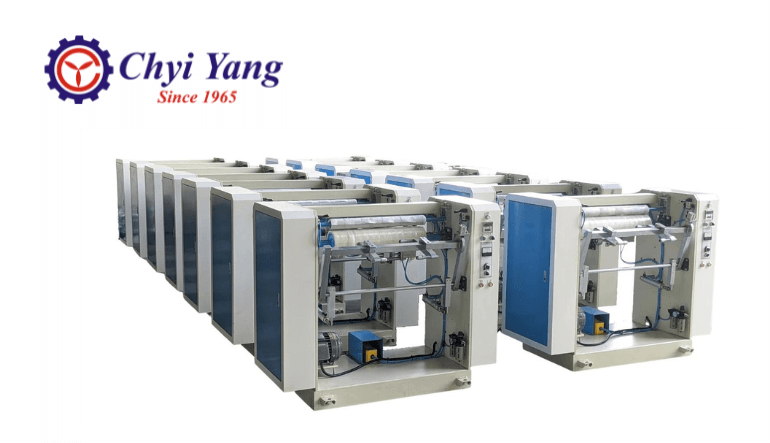

CHINAPLAS Exhibitor Interview: CHYI YANG PE Stretch Film/Cling Film Wrapping Machine

CHYI YANG, the products launched at the exhibition are PE stretch film/cleaning film wrapping machine: RW-1 Series and RW-2 Series. The fully automatic RW-1 series has a rewinding width of 300mm, a length of 30–300M, and a speed of 0–600 (M/Min). Increase work efficiency. The other is the RW-2 series, with a wrapping width of 200-550mm, a wrapping length of 30–1,000M, and a speed of 0–150 (M/Min). These two products can support industrial and food grade cleaning films, and are widely used and trusted.

Plastic Pelletizer Comparison for In-house Plastic Film Recycling

In-house plastic film is usually clean and can be reprocessed right away without extra procedures. But what kind of recycling equipment you should invest in to make the best use of it? For in-house plastic film recycling, POLYSTAR has two recommended solutions: the Cutter-compactor Plastic Pelletizer, Repro-Flex, and the Air-cooled Plastic Pelletizer, Repro-Air. Both recycling machines can process HDPE, LDPE, and LLDPE clean post-industrial plastics like film, bags, T-shirt bag cut-offs, and edge-trim waste. However, Repro-Flex can deal with more kinds of plastics such as PP, PS, PA, etc. Let’s take a closer look at what they feature and their advantages, which are the main differences between them.

Eterlong's Evolution from Blown Film Dies Technical Skill to Comprehensive Blown Film Machines

For over 50 years of manufacturing experience in Blown Film Dies, Eterlong is dedicated to upgrade and optimize the design constantly to meet the market trend and the ever-changing technology.

Outstanding Quality Blown Film Machine Gets a Vietnam-listed Company's Favor

One of the listed companies in Vietnam purchased three sets of blown film machine from Chyi Yang 20 years ago. Afterward, in response to enlarged scope of the company and to reduce the cost, they turned to import equipment from China with lower price. However, the quality of film produced from China machine did not meet Japanese customer’s standard and up to 20 freight containers of products were returned in one transaction.

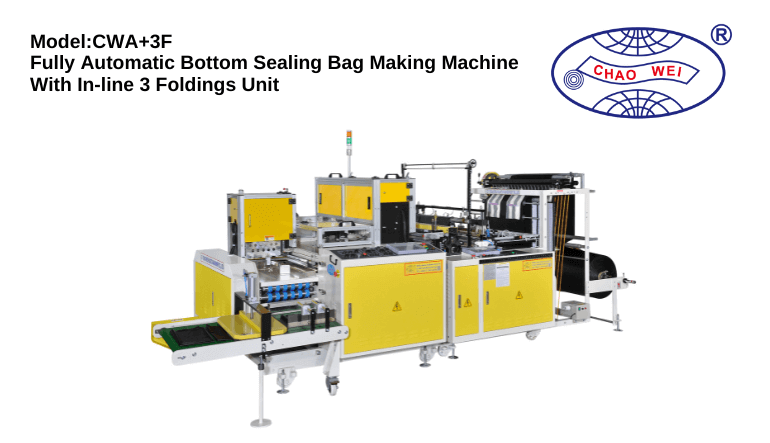

CHAO WEI: Bottom Sealed Bag Making Machine with In-line Folding Unit

Fully automatic bottom sealing bag making machine with in-line 3-foldings unit folds bags twice along their length and once along their width, achieving speeds up to 80 bags/min. Features include precise length control with YASKAWA servo motors, dual touch screens, German-made SICK photocell for printing alignment, and automatic stoppage for jams, film depletion, temperature anomalies, or print misalignment.