LATEST UPDATE Subscribe Now

TungYu: Revolutionizing the Industry and Shaping a Greener Future

TungYu, a name synonymous with innovation in the rubber industry, is thrilled to announce our participation in two of the most prestigious industry events: RubberTech 2024 in Shanghai, China, and TaipeiPlas 2024 in Taipei, Taiwan. At TaipeiPlas 2024, TungYu will be focusing on the theme of "Shaping a Greener Future of Sustainable Forming Technologies.

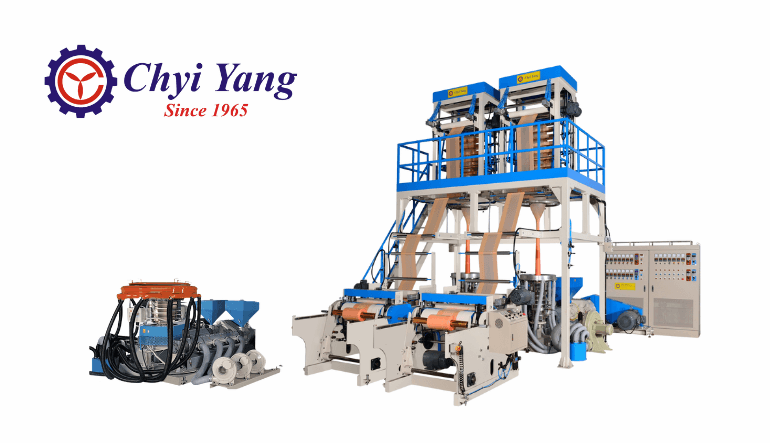

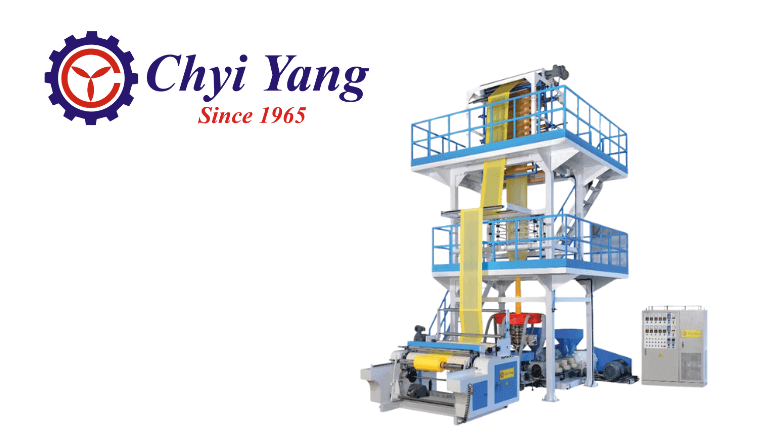

The Smart Choice: CHYI YANG Yang's ABA 3-Layer Co-Extrusion Reach the Perfect Combination of High Performance and Precise Cost Control

With consistently increasing sales and highly positive feedback from customers, Chyi Yang’s newly launched ABA 3-Layer Co-Extrusion has quickly gained traction in the market. Its strong competitive edge in reducing production costs, improving efficiency, and maintaining superior product quality has made it a standout performer. The machine’s impressive sales and exceptional customer satisfaction have solidified its position as a rising star in the industry.

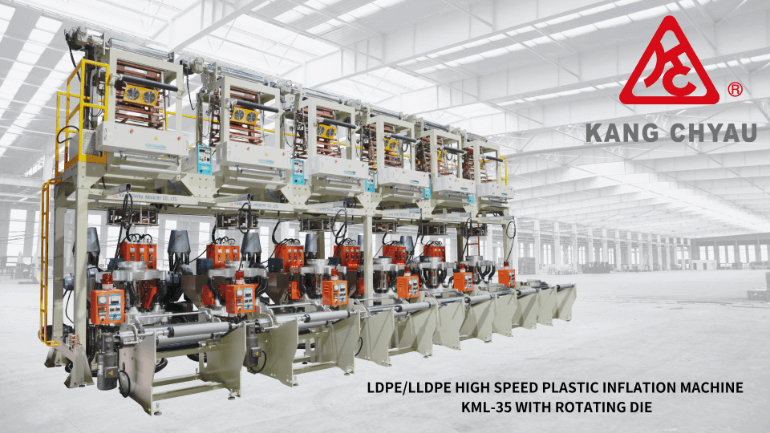

From General to Customized Blown Film Machinery: How Kang Chyau Evolved into a Professional Blown Film Consultant

Taiwan's Plastics and Rubber machinery industry has long been renowned for its high quality and customization capabilities. PRM's Spotlight initiative this year aims to highlight the unique strengths of Taiwanese machinery suppliers on a global scale, particularly their ability to offer customized solutions during the innovation and R&D process, allowing international clients to better understand and recognize Taiwanese manufacturers.

FORMAX: Precise Measurement is Key to Success

Precise measurement is the key to success Formax: “Attention to detail is what maximizes value.” Founded in 1992, Formax is committed to becoming a leader in the global plastics processing industry. Equipped with strong R&D capabilities, we provide professional, high-quality, high-performance plastics auxiliary equipment and automation systems to create the utmost value for our clients. As an expert in production systems, FORMAX believes its expertise can help clients enhance efficiency and solve quality issues in production. FORMAX embraces "Precision, Aesthetics, Operation Convenience" in reestablishing the focus of its R&D and undergoes comprehensive enhancement for its central conveying systems, dosing and mixing equipment, feeding and conveying equipment, drying and dehumidifying equipment, heating and cooling equipment, as well as its granulator and recycling equipment; ensuring that FORMAX product series continue to add value to the global plastics industry.

CHYI YANG: Transforming Waste into Gold, ABA Co-extrusion Machine Revolutionized Bag Manufacturing

The unique die head design of the ABA co-extrusion machines offers producers cost management flexibility by incorporating an middle layer of recycled material or calcium carbonate compound, effectively reducing raw material expenses. This not only maintains competitiveness in raw material prices but also aligns with environmental trends.

Plastic Recycling Hero Behind the Scenes, Geording Machinery Becomes a Trusted Manufacturer with Customization Capabilities

Plastic waste recycling has long been a symbol of green sustainability. With the rapid advancement of recycling technologies, applications have become increasingly diverse and abundant. The World Economic Forum predicts that by 2030, the global circular economy will reach $4.5 trillion. Internationally, there are new applications emerging, such as environmentally friendly building materials made from PET bottle bricks and eyeglass materials made from discarded fishing nets. Coca-Cola Taiwan has also invested significant research and development efforts, spending seven years to develop products using 100% recycled plastic bottles, setting a new milestone in plastic recycling applications.

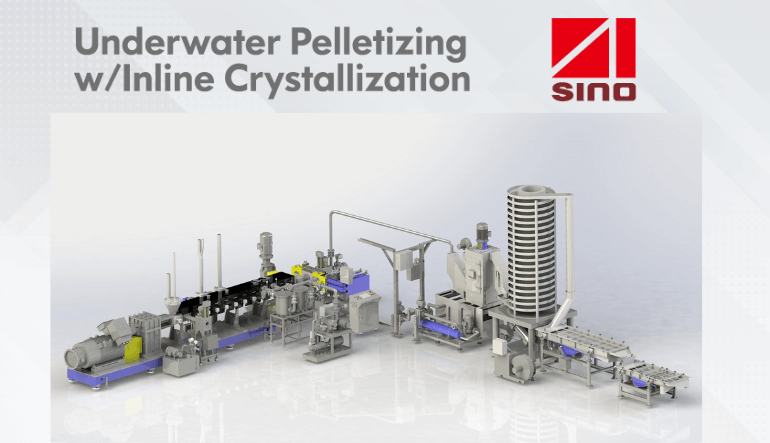

Sharing Success Stories: How Choosing Sino-Alloy, the Compounding Expert, Can Bring You Production Advantages

Sino-Alloy Machinery Inc. is a leading company specializing in the manufacturing of co-rotating twin-screw extruders, widely applied in various fields such as engineering plastics, adhesives, and plastic wood compound. Committed to continuously improving efficiency, quality, and reliability, Sino has attracted numerous domestic and international buyers. Sino's technology not only helps customers enhance production efficiency but also demonstrates significant achievements in environmental protection and energy conservation, further consolidating its leadership position in the market.

Tips for choosing a high quality PVC Pelletizing Extrusion Line

Polyvinyl Chloride (PVC) is the world’s third most-widely used synthetic plastics succeeding to polyethylene (PE) and polypropylene (PP). The annual demand for PVC keeps increasing. Usually, the PVC products are made by processing the PVC materials in a pellet form that is obtained by a PVC pelletizing extrusion line. Due to facts of that PVC polymers are sensitive to thermal & shearing stress, characteristic considerations on the mechanical and controlling aspects are critical for a high performance PVC pelletizing extrusion line.

Scientific Molding Thinking: Molding is a Science not an Art

Injection molding is the process of converting plastic materials into flowable molten plastic materials by an injection molding machine, and injecting them into a mold cavity where they are cooled and solidified to form the final product. Plastic materials are less expensive to obtain compared with other materials such as metal, wood, and ceramics. In addition, it is easy to produce complex geometric products in large quantities with plastic materials, so people constantly extend the application of plastic products to various types of products. However, the complex flow behavior of plastics due to their viscoelastic property has led to many specious and erroneous experiences in injection molding, which may easily mislead the direction of problem solving.

The Fastest Rewinding Machine Made In Taiwan

Chyi Yang developed a new PE Stretch Film Rewinder Machine. The Rewinder machine mainly is used in rewinding stretch film & cling film. This machine is fully automatic, it can feed the paper core, rewind film, cut film and change paper core, glue & label automatically. Chyi Yang is expert in developing PE stretch film whole equipment for more than 50 years.

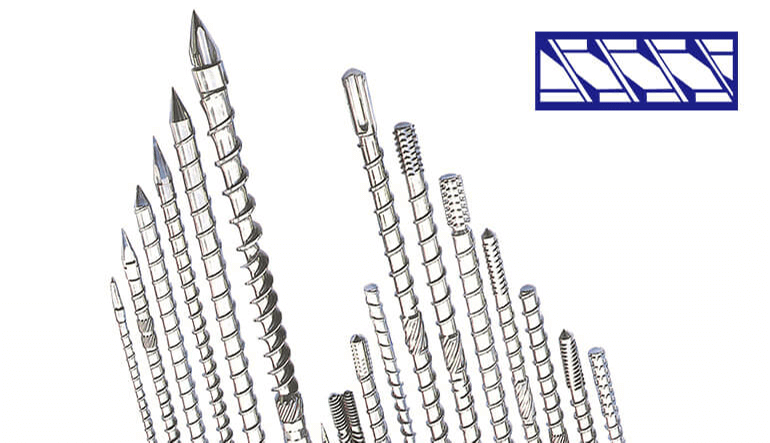

Customized Perfection: How LUNG CHANG Meets Clients’ Needs with Precision Screws and Barrels

During the pandemic, one of the biggest challenges for the plastic machinery industry is the travel and logistics limitations. No matter after sales services of the manufacturers are good, once it comes to the maintenance and parts requirements, current transportation and logistics obstacles might cause the manufacturers delay in their business. Therefore, many plastic machine manufacturers prefer to use the parts, such as screws and barrels, that are high quality and meet customers' requirements precisely in their machines. In this case LUNG CHANG is one step ahead in the industry with its reliable extruder screws and barrels as well as injection molding machine screws and barrels.

TungYu Servo Press: Revolutionizing Manufacturing with Sustainable Power

Are you looking to enhance your manufacturing processes while minimizing environmental impact? TungYu's advanced all-electric servo press offers a sustainable and efficient solution. By replacing traditional hydraulic systems with high-performance servo motors, our servo press achieves significant energy savings and a reduced carbon footprint.