Sharing Success Stories: How Choosing Sino-Alloy, the Compounding Expert, Can Bring You Production Advantages

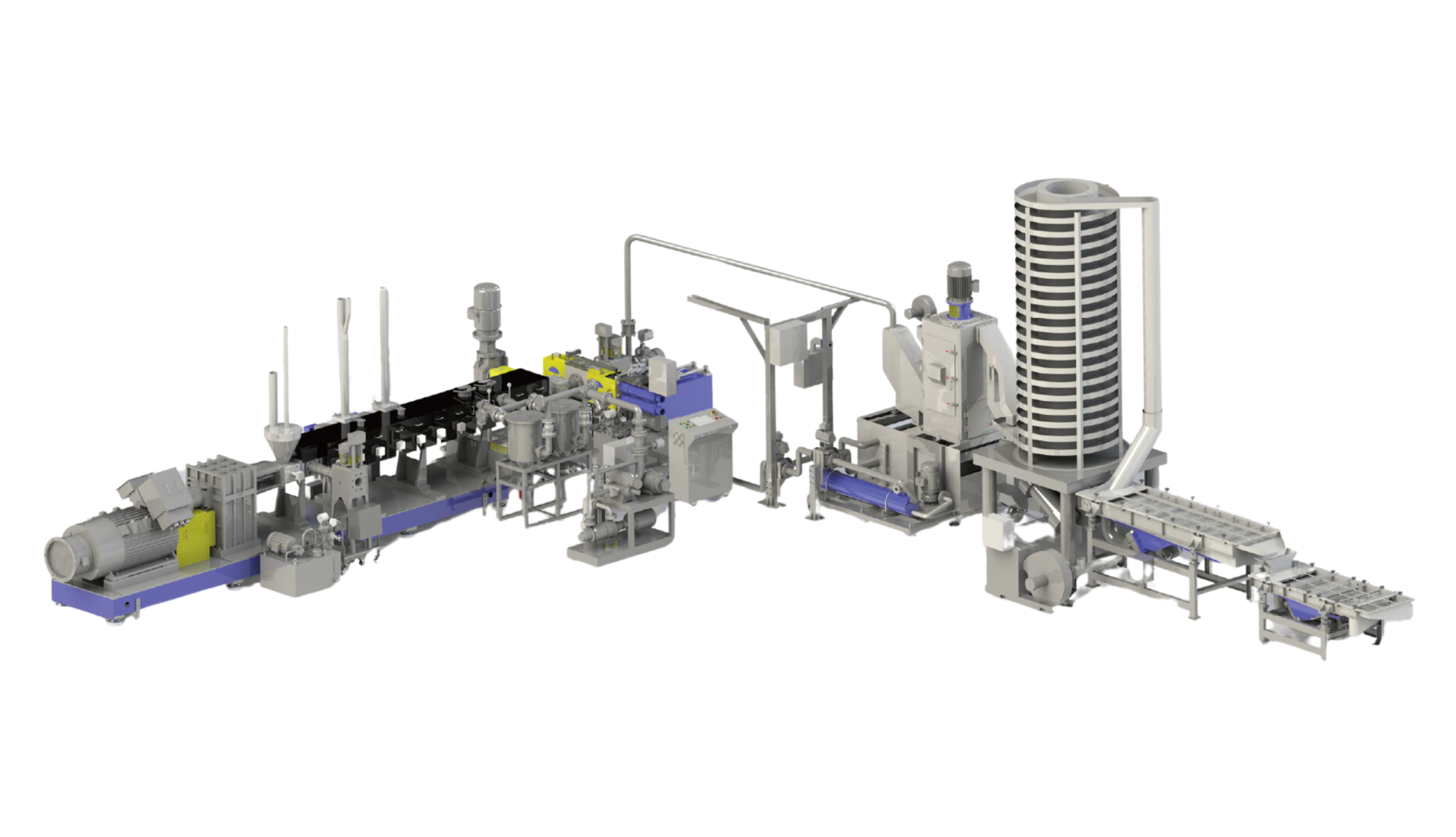

Sino-Alloy Machinery Inc. is a leading company specializing in the manufacturing of co-rotating twin-screw extruders, widely applied in various fields such as engineering plastics, adhesives, and plastic wood compound. Committed to continuously improving efficiency, quality, and reliability, Sino has attracted numerous domestic and international buyers. Sino's technology not only helps customers enhance production efficiency but also demonstrates significant achievements in environmental protection and energy conservation, further consolidating its leadership position in the market.

PET Recycling Viscosity Enhancement Breakthrough: How Sino-Alloy Overcame Technical Bottleneck

PET recycling has always been a crucial aspect of plastic recycling, particularly with bottles and spinning accounting for a significant proportion. However, during the recycling process, the IV value of PET gradually decreases, directly impacting product quality and making recycled PET unsuitable for its original applications. Therefore, viscosity enhancement technique becomes the key technology to address this issue.

Sino's equipment primarily focuses on viscosity enhancement treatment for PET film recycling, particularly achieving significant results in solid-state viscosity enhancement technology, while also continuously researching liquid-state viscosity enhancement technology. Furthermore, Sino's equipment can achieve inline crystallization, a pre-crystallization technology carried out during the pelletizing process that prevents moisture absorption, ensuring the stability of particle humidity and moisture content, thereby greatly improving product quality. In addition, this technology offers advantages in energy savings, time savings, and reduced labor input, making the entire production process more efficient.

The application of this technology enables Sino's clients to significantly improve the utilization rate of recycled PET, especially in the bottle recycling process where the requirements for IV values are extremely stringent. Through Sino's solid-state viscosity enhancement technology, clients can not only effectively improve the quality of recycled materials but also save on production costs, earning Sino a good reputation in the PET recycling market.

Inline crystallization, a pre-crystallization technology carried out during the pelletizing process that prevents moisture absorption

Specially Designed Rubber Shredding Equipment: Effectively Enhancing Rubber Shredding and Processing Efficiency

Natural rubber is difficult to handle due to its high viscosity at room temperature, which has always been a challenge for many rubber processing companies. When rubber is purchased in large blocks, it needs to be shredded before further processing. However, due to the properties of rubber, shredded rubber tends to stick together, making it difficult to feed into machinery normally.

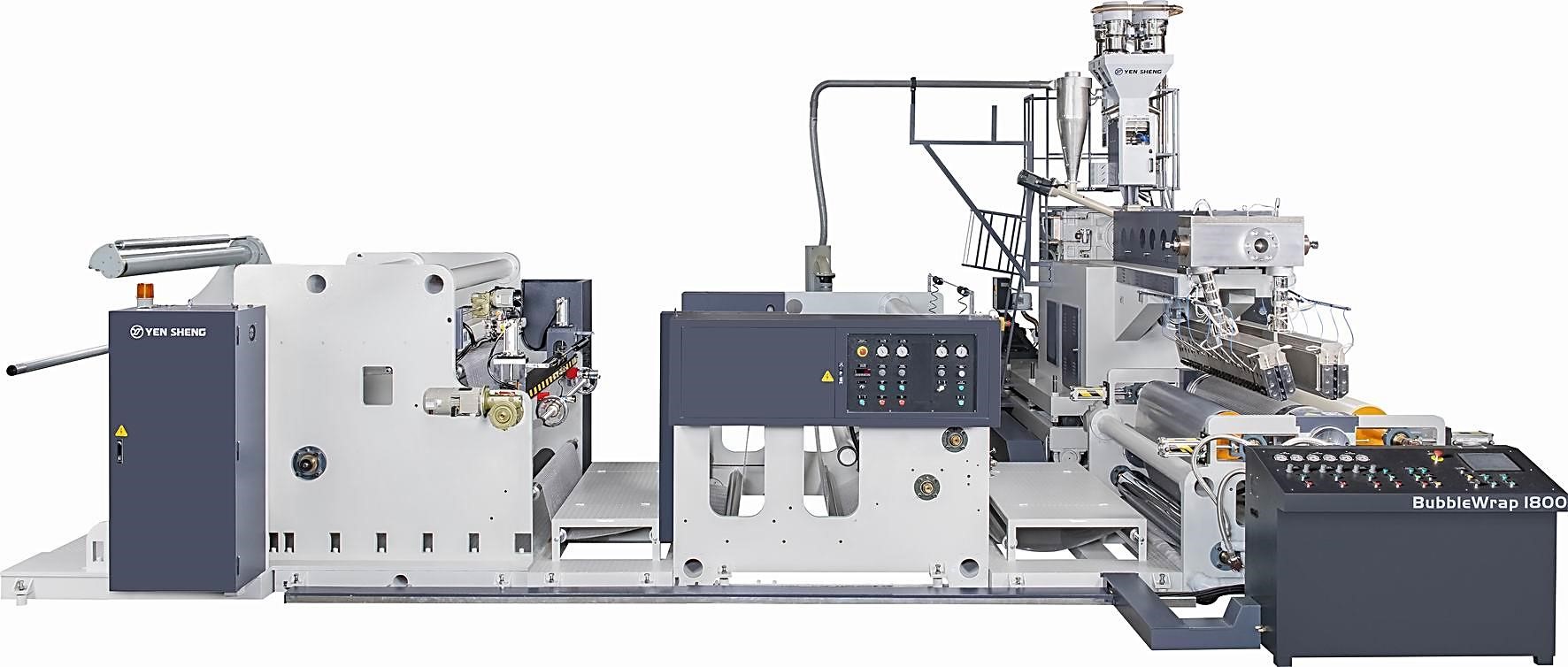

Sino developed a high-efficiency shredder to address this problem. Its design cleverly combines the angles and number of blades, successfully resolving the issue of rubber shredding viscosity. Traditional methods often rely on vulcanization treatment, but this approach can damage the rubber's viscosity, failing to achieve the desired effect. Sino's innovative technology avoids this problem, allowing shredded rubber to feed smoothly into machinery, thereby enhancing production efficiency. This shredding technology is applicable to the processing of adhesive products such as tape production. Sino's equipment excels in the shredding stage, and the downstream can be connected to lamination machines for more complex product processing. This integrated solution allows Sino-Alloy's customers to achieve higher efficiency and quality assurance across all stages of rubber processing.

Continuous improvement of equipment and technology, Sino will continue to provide efficient solutions to customers around the world

Through continuously improving equipment and technology, Sino will continue to provide efficient solutions to global customers. Whether it is viscosity enhancement technology for PET recycling or rubber shredding and processing, Sino's equipment demonstrates outstanding performance and stability. These successful cases not only reflect Sino's advantage in technological innovation but also showcase its deep understanding of customer needs and agile responses.

If you are looking for machinery equipment that can enhance production efficiency, save energy, and ensure product quality, Sino is undoubtedly your best choice.

Sino-Alloy Machinery Inc. is a leading company specializing in the manufacturing of co-rotating twin-screw extruders, widely applied in various fields such as engineering plastics, adhesives, and plastic wood compound. Committed to continuously improving efficiency, quality, and reliability, Sino has attracted numerous domestic and international buyers. They tackle challenges including the recycling and regeneration of PET, and the shredding and processing of natural rubber. In these successful cases, Sino's technology not only helps customers enhance production efficiency but also demonstrates significant achievements in environmental protection and energy conservation, further consolidating its leadership position in the market.

PET Recycling Viscosity Enhancement Breakthrough: How Sino-Alloy Overcame Technical Bottleneck

PET recycling has always been a crucial aspect of plastic recycling, particularly with bottles and spinning accounting for a significant proportion. However, during the recycling process, the IV value of PET gradually decreases, directly impacting product quality and making recycled PET unsuitable for its original applications. Therefore, viscosity enhancement technique becomes the key technology to address this issue.

Sino's equipment primarily focuses on viscosity enhancement treatment for PET film recycling, particularly achieving significant results in solid-state viscosity enhancement technology, while also continuously researching liquid-state viscosity enhancement technology. Furthermore, Sino's equipment can achieve inline crystallization, a pre-crystallization technology carried out during the pelletizing process that prevents moisture absorption, ensuring the stability of particle humidity and moisture content, thereby greatly improving product quality. In addition, this technology offers advantages in energy savings, time savings, and reduced labor input, making the entire production process more efficient.

The application of this technology enables Sino's clients to significantly improve the utilization rate of recycled PET, especially in the bottle recycling process where the requirements for IV values are extremely stringent. Through Sino's solid-state viscosity enhancement technology, clients can not only effectively improve the quality of recycled materials but also save on production costs, earning Sino a good reputation in the PET recycling market.

Specially Designed Rubber Shredding Equipment: Effectively Enhancing Rubber Shredding and Processing Efficiency

Natural rubber is difficult to handle due to its high viscosity at room temperature, which has always been a challenge for many rubber processing companies. When rubber is purchased in large blocks, it needs to be shredded before further processing. However, due to the properties of rubber, shredded rubber tends to stick together, making it difficult to feed into machinery normally.

Sino developed a high-efficiency shredder to address this problem. Its design cleverly combines the angles and number of blades, successfully resolving the issue of rubber shredding viscosity. Traditional methods often rely on vulcanization treatment, but this approach can damage the rubber's viscosity, failing to achieve the desired effect. Sino's innovative technology avoids this problem, allowing shredded rubber to feed smoothly into machinery, thereby enhancing production efficiency. This shredding technology is applicable to the processing of adhesive products such as tape production. Sino's equipment excels in the shredding stage, and the downstream can be connected to lamination machines for more complex product processing. This integrated solution allows Sino-Alloy's customers to achieve higher efficiency and quality assurance across all stages of rubber processing.

Continuous improvement of equipment and technology, Sino will continue to provide efficient solutions to customers around the world

Through continuously improving equipment and technology, Sino will continue to provide efficient solutions to global customers. Whether it is viscosity enhancement technology for PET recycling or rubber shredding and processing, Sino's equipment demonstrates outstanding performance and stability. These successful cases not only reflect Sino's

advantage in technological innovation but also showcase its deep understanding of customer needs and agile responses.

If you are looking for machinery equipment that can enhance production efficiency, save energy, and ensure product quality, Sino is undoubtedly your best choice.

SINO-ALLOY MACHINERY INC. manufactures a full line of Co-Rotating Twin Screw Extruders. Typical applications for our product line include Polymer Alloying, Reinforcement, Reaction, Degassing, Master Batch Manufacture, and Filling. We also offer an extensive line of Auxiliary Equipment to complement our extruders, as well as Turn-Key Compounding Technology in conjunction with our affiliate POLYALLOY INC.

Sino-Alloy's family of PSM co-rotating twin-screw extruders have been developed for use anywhere from laboratories and institutions to large-volume production facilities. Each new model of PSM extruder arguably leads the plastic compounding industry with the integration of experience and technology. Breakthrough accomplishments at Sino-Alloy are continually changing the nature of compounding.

All PSM series machines are production-tested through runs at POLYALLOY INC. prior to new product announcements or market availability. Sino-Alloy's team of skilled and educated personnel closely monitors hardware reliability and integrated software performance to detect faults and opportunities for improvement.

Our experience enables us to continuously improve the efficiency and quality of our machines while meeting and exceeding the standards expected by our customers.