Plastic Recycling Hero Behind the Scenes, Geording Machinery Becomes a Trusted Manufacturer with Customization Capabilities

Plastic waste recycling has long been a symbol of green sustainability. With the rapid advancement of recycling technologies, applications have become increasingly diverse and abundant.

The value of plastic recycling continues to increase, reaching new highs

The World Economic Forum predicts that by 2030, the global circular economy will reach $4.5 trillion. Internationally, there are new applications emerging, such as environmentally friendly building materials made from PET bottle bricks and eyeglass materials made from discarded fishing nets. Coca-Cola Taiwan has also invested significant research and development efforts, spending seven years to develop products using 100% recycled plastic bottles, setting a new milestone in plastic recycling applications.

Certified by the Japanese government, Geording Machinery from Taiwan turns garbage into gold

However, for recycling machinery factories, achieving effective recycling is not easy. It requires advanced technology and equipment to handle various types of plastic waste, as well as the ambition to keep pace with the times and the willingness to adjust. Geording Machinery, based in Taiwan, focuses on the production of rubber and plastic recycling machinery. Since its establishment in 2004, Geording has been renowned for its recycling plant planning and granulation technology, with customers spread across the world.

In recent years, Geording has collaborated with the Japanese government to build a tourism factory in Osaka themed around urban waste recycling. This factory mainly recycles various consumer goods waste generated in cities, such as PET bottles, plastic toys, and garbage bags. The recycling line equipment used in this tourism factory is produced by Geording Machinery, including sorting, washing, granulation, and transportation processes used in waste treatment, as well as the overall steel structure of the building, which is also designed by Geording, handling the entire plant planning.

Due to the enormous amount of waste generated by consumer goods in cities, which has already caused significant damage to the environment, the Japanese government came up with the idea to collaborate with recycling companies to showcase the complete transformation process of urban waste to the public, and Geording supported this concept with actions. This not only amazed the Japanese but also firmly established Geording as the driving force behind waste recycling and reformation.

Differentiated by a willingness to listen to customers, customization creates endless business opportunities

Why can Geording become one of the few recycling machinery companies that meet Japan's high standards and create products that meet customer needs?

When we posed this question, Jessica, a Geording business representative, answered confidently. She believes that to achieve more efficient reuse of recycled materials, both hard and soft strengths are indispensable.

"In terms of hard strengths, Geording can maintain a low moisture content of plastics to ensure product quality, and even meets Japan's requirements for low noise from machinery, which many manufacturers cannot achieve. In terms of soft strengths, Geording is willing to listen to customers and willing to change its original practices to achieve improvement, which is also why Geording's machinery design is more flexible."

Not only listening but also willing to change for customers.

A customer from Hokkaido, Japan, once cooperated with Geording. The customer requested to directly shoot mixed plastic waste with various impurities into plastic bricks with card slots without washing or granulating, hoping to mass-produce them as green building materials.

This is completely different from the design and process of general recycling machinery, but Geording is willing to tailor products to meet the needs of customers. Even if it means breaking existing conventions and possibly spending more time and effort, Geording is willing to do so, which truly demonstrates Geording's solid capabilities in innovation and customization.

"We can do what others can't!”

Geording's slogan also emphasizes their uniqueness. Jessica delves into why Geording can innovate together with customers: "It is not easy for machinery manufacturers to achieve innovation and customization, but Geording is already very familiar with this path and continues to improve its technology, which is why we are different."

In the future, Geording will continue to face new challenges.

About GEORDING

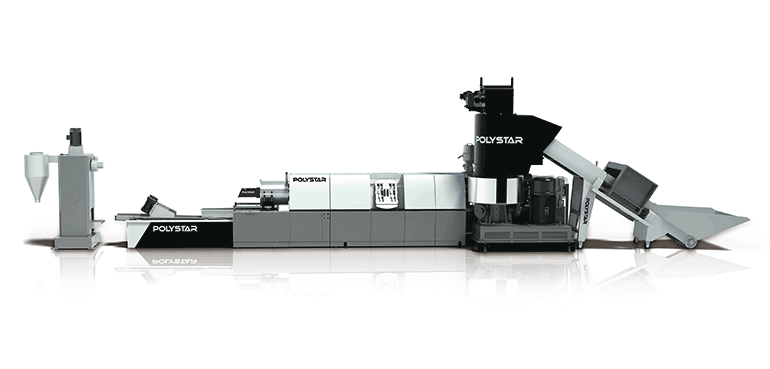

GEORDING MACHINERY, the manufacturer of plastic recycling and pelletizing machine stands out in Taiwan. Pursuing innovation and excellence with more than three decades of experience and expertise, we specialize in recycling and pelletizing equipment of rubber and plastic waste; plastic waste crushing, washing and drying line; high speed dyeing and pelletizing production line; automatic batch weighing and mixing system; compounding and pelletizing CaCO3 or other composite materials such as rice husk, EVA, rubber, TPR, PVC, etc.; color master-batch; RDF-5 pelletizing; plastic waste crushing/shredding; plastic rubbing and drying; sheet extrusion of PE, PP, and PVC; planning of entire plant equipment and customized equipment and components.