Eterlong's Evolution from Blown Film Dies Technical Skill to Comprehensive Blown Film Machines

For over 50 years of manufacturing experience in Blown Film Dies, Eterlong is dedicated to upgrade and optimize the design constantly to meet the market trend and the ever-changing technology.

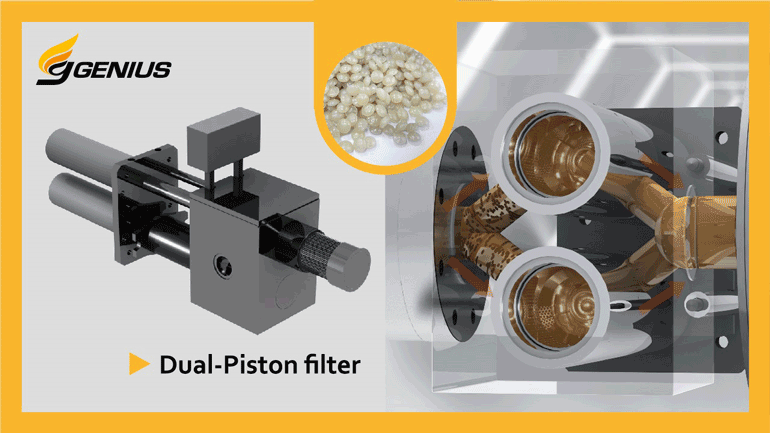

Blown Film Dies, as the heart of Blown Film Machines which perform in the main role of producing perfect films. When receiving the new inquiries, we would require and discuss the details specs with the clients, we care about every single character and condition.

The same model of Die Head with different dimension of Lip Diameter, Die Gap, Feeding Hole, No. of Spiral Channels, Channel Pitch, Channel Width and so on, it would come out with different results surely. Moreover, it is also related to the Screw Diameter, Horse Power of the Main Motor, Film Width, Film Thickness, Output, Air Ring, Air Blower etc.

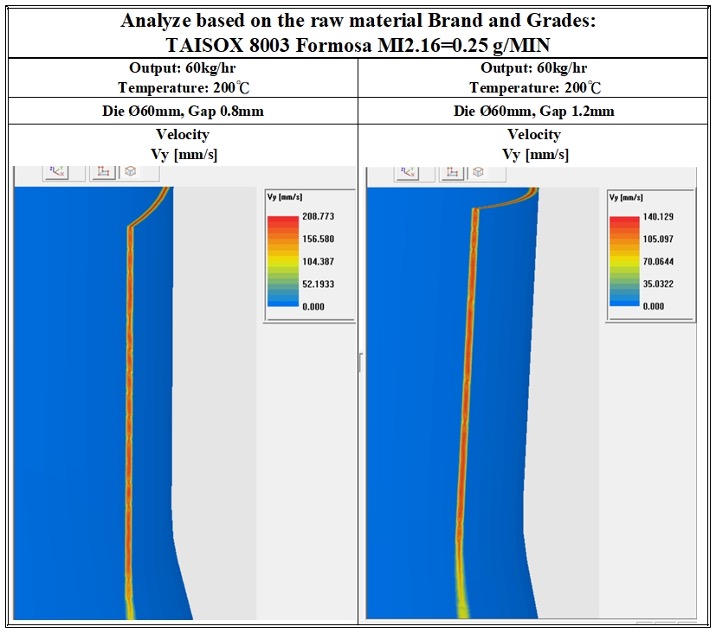

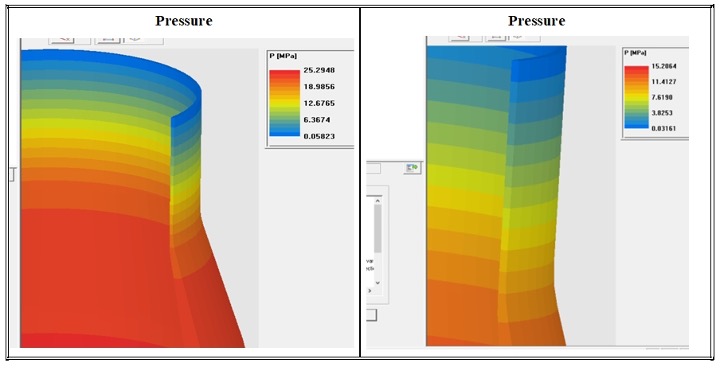

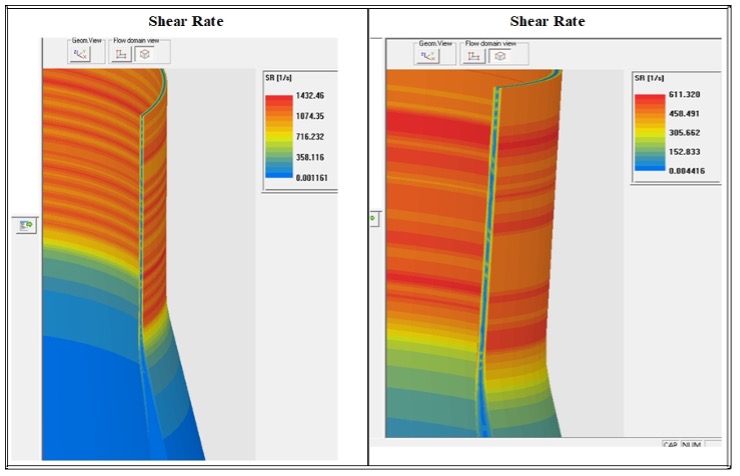

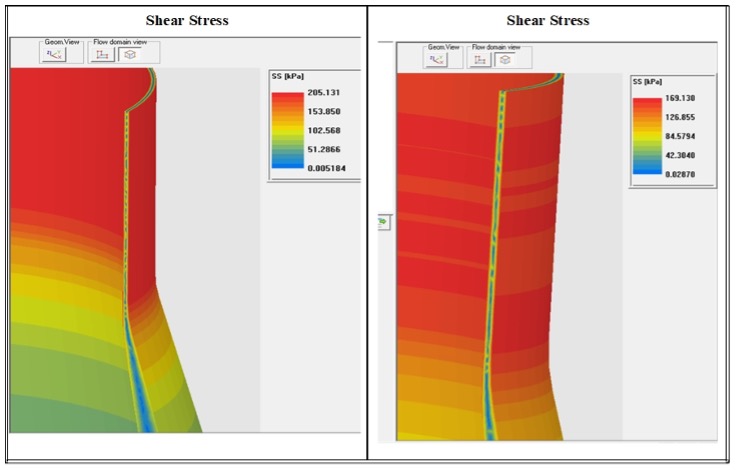

Moldflow Technology

Nowadays, there is a variety of raw materials with various quality, it tends to push us to move forward innovating ever-growing technology to come up with the challenges.

In order to suit for the changes and the requirements for market, Eterlong is dedicated in VEL™ (Virtual Extrusion Laboratory™) Moldflow analysis to upgrade our technology in order to support our clients. We also offer an additional service while they are using special materials and not sure about its actual character, especially for multi-layer projects. Customers would send some of the raw materials to us for analyzing and find out the suitable design for each component.

Innovation Makes Perfect

As a leading Blown Film Die design and manufacturer, we delve into multi-layer design and we strive to enlarge technological cooperation and hold meetings from time to time for technical exchange with global machinery to enhance and offer superior products to our customers. This is never enough, we must remember “Always strive to improve yourself to become better today than you were yesterday.”, said our chairman, Ms. Misy.

Eterlong Co., Ltd. , based in Tainan, southern Taiwan, specialized in the customization of components for semiconductor machinery, sheet metal processing, and the integrated automated control systems. With rich experience in highly precise machinery and metal processing, Eterlong’s products have garnered customers’ acclaim. In spring 2023, after a three-year global Covid-19 impact, the international markets are rebounding, leading to a robust demand surge. A chance encounter led to a swift merger with Hsin Long, a professional production of blown film machine manufacturer in Tainan more than 50 years. Both parties quickly agreed on integration, leveraging Eterlong’s extensive production facilities and acquiring cutting-edge intelligent equipment to expand production capacity.

Eterlong firmly believes that dedicated pursuit of craftsmanship excellence and a focus on perfect details are our growth foundations. Through the integration of brand and technology, we aspire to be the professional leading force in the blown film market, collaborating with industry peers for the blown film industry prosperity.