THE LATEST GENERATION OF PET BOTTLE WASHING LINE—ES PROCESS

THE LATEST GENERATION OF PET BOTTLE WASHING LINE—ES PROCESS

In response to the PET industry’s quest to increase recycled content by producing high-quality rPET flakes for high-end applications, BoReTech has leveraged its 30 years of experience in recycled polyester industry and developed a total solution for plastic recycling, endeavoring to be a global pioneer in plastic recycling ingenuity.

BoReTech revolutionizes its recycling process and technology with the unveiling of ES Process PET bottle washing line. The cutting-edge system boasts an array of enhanced features, and the integrated functionality of a turnkey recycling system maximizes equipment performance, making rPET flakes of premium quality.

ADVANCEMENTS IN THE LATEST ES PROCESS PET BOTTLE WASHING LINE

COMPACT FOOTPRINT

Occupying a smaller footprint with approximately a 25% reduction compared to traditional processes, BoReTech system maximizes cost savings for customers in terms of land use and factory construction for equivalent processing capacities.

HIGHLY MODULARIZED DESIGN

Highly modular, it achieves synergy between functional machines as well as modules after integration, integrating processes seamlessly to reduce space requirements and enhance overall efficiency.

SUPER-CLEAN WASHING PERFORMANCE

Delivering high-quality finished products with minimized impurity content, leading to 25% up in filtration performance, our system exhibits exceptional cleaning performance, ensuring stable product quality suitable for both bottle-to-bottle and micro denier filament production.

COST-EFFECTIVE PRODUCTION

With low production costs and a reduction of approximately 1/3 in online labor requirements, the system emphasizes machine automation, ease of maintenance, and high levels of efficiency, optimizing unit energy consumption.

SUSTAINABILITY

Environmentally sustainable, the system incorporates a 13.3% reduction in average energy consumption per ton of output through precise online filtration of chemical water, minimizing overall resource usage.

(Insert a YouTube video here.)

https://www.youtube.com/watch?v=196IAu-humc

ES Process Features a Range of High-Performance Equipment and Modules.Here, we focus on introducing three of them:

1. Integrated Washing, Label Removal, and Label Separation System

Boretech's integrated washing, label removal, and label separation system combines three critical functions into one. This innovative solution reduces the number of machines required and minimizes factory space usage. It significantly improves label removal conditions, enhances label separation rates, and ensures superior product quality. At the same time, it lowers environmental impact, achieving a balance between production efficiency and sustainability.

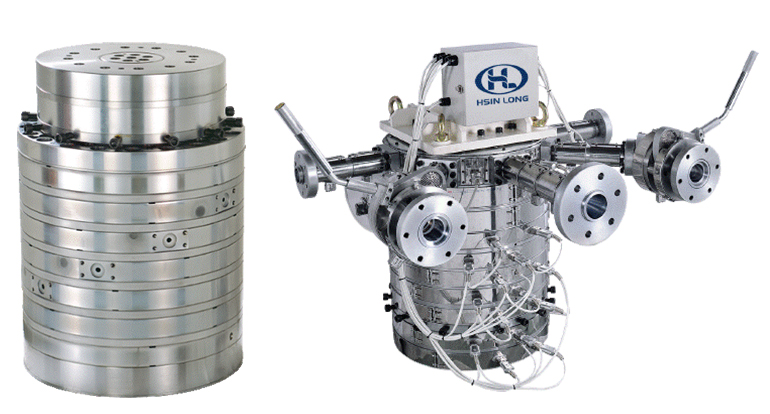

2. Mega Aspirator

The Boretech multi-channel air separation machine is a cutting-edge, high-efficiency label removal device. It is specifically designed to handle materials with high residual label content, delivering stable and highly efficient label removal while minimizing material loss.

3. Intensive Washing Module

The intensive washing module features a specially designed system, delivering excellent cleaning performance and effectively removing impurities from PET flakes with almost zero detergent residue. The cleaned flakes improve filtration efficiency during the downstream granulation process by 25%, ensuring the production of high-quality recycled PET flakes. These flakes are not only suitable for bottle-to-bottle production but also meet the stringent requirements of micro denier filament manufacturing.

Success Stories: Driving Global Plastic Recycling

Boretech’s innovative equipment is successfully running in multiple international client projects:

1. A certain company in South Korea

Boretech's South Korean client, is an enterprise that took the lead in getting involved in the production and recycling business of PET bottles and has been maintaining close cooperation with us all along.In 2022, Boretech provided Samyang with an ES process PET bottle washing line with an input capacity of 7 tons/hour, and the recycled rPET is primarily for bottle-to-bottle application.

▲Project in South Korea

2. A certain company in Vietnam

Boretech's Vietnamese client, is a leading local plastic brand, aiming to become a leading supplier of rigid plastic packaging and household products in the ASEAN region.The line has an annual processing capacity of 20,000 tons, offering enhanced cleaning performance and an advanced water filtration system. This ensures higher-quality rPET and more stable product consistency. The recycled rPET flakes are used in downstream food-grade granulation processes for Duy Tan's own beverage packaging plants.

▲Project in Vietnam

Shaping the Future of the Industry

Boretech is committed to providing customized PET bottle recycling and washing solutions for every client. The company’s R&D efforts for recycling HDPE, PP lunch boxes, and PET trays have also been validated and are ready to be launched into the market.

With cutting-edge technology and extensive industry experience, Boretech helps clients achieve both environmental and economic benefits. If you would like to learn more about our technologies, processes, or customized products, feel free to contact us. Boretech looks forward to working with you to shape a greener future for the plastic recycling industry!

More information, please feel free to contact [email protected]