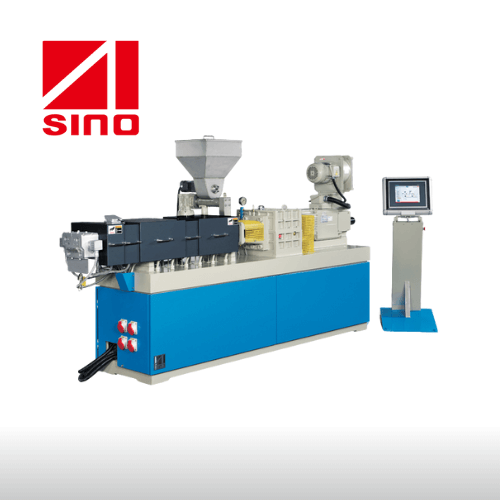

Compact Co-Rotating Twin Screw Extruder-PSM30A

Categories : Twin Screw Extruders

The PSM30A Co-Rotating Twin Screw Extruder has an ultra compact design and is easy to operate. It is designed for optimal double flight screw elements, which maintains the same deep groove, high torque characteristics of our larger full-production models. This compatibility allows for a direct transfer of experimental process parameters to the full production model without conversion factoring. All PSM30 series extruders meet or exceed CE and international safety standards. Sino-Alloy can also design a custom line to meet your specifications.

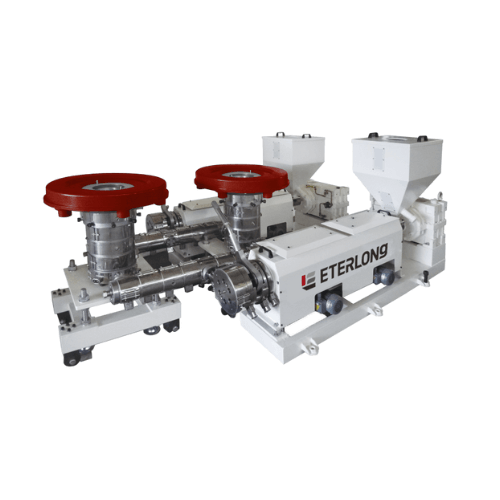

Co-Extruder, Co Extrusion Machine

Categories : Extrusion Lines For Pipes and Profiles

Part for indoor and outdoor application: Door Frames, Furniture Components, Spacing Panels, etc.

LDPE / HDPE Single Layer BLOWN FILM MACHINE

Categories : Blown Film Extruders

LDPE and HDPE Blown Film Machine is commonly used type in the blown film industry. This is the most economical type which HSIN LONG has rich manufacturing experiences for many years. Most of its final applications are widely used in our daily life which from people’s livelihood to the rising industry of biodegradable. Despite there are lots of advantages in other types of Blown Film Machine, Single Layer LDPE and HDPE Plastic Film Blowing Machine is still a great choice for use of many applications.

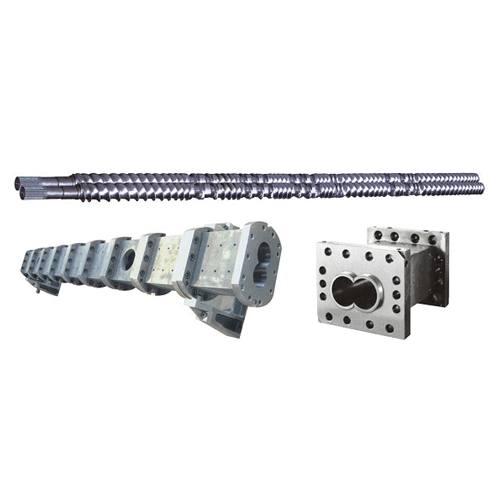

Co-Rotating Twin-Screw Extruder Screws / Barrels

Categories : Screws and Barrels

The screw and barrel Nan Yun designes and manufactures for twin-screw extruder enables the continuous production of highly homogeneous and finely structured products, with more than 20 years of experience on twin extruder screw design, Nan Yun is able to provide highest production quality for customers

Pellet Extruding Machines Screws / Barrels

Categories : Screws and Barrels

As leading company of Screws and barrels in Taiwan, Nan Yun is able to provide the highest quality screw and barrel for Extruder Machine. We are continually researching new screw and barrel materials that would best fit the needs for pellet extruder or plastic pelletizing machine, which results in better mixing, and critical melt quality. Nan Yun's engineers work with our customers to provide the best possible extruder screw design for extruder machine such as PVC pelletizing machine, PE pelletizing equipment, Plastic pellet extruder.

Sheet Extruding & Laminating Machines Screws/Barrels

Categories : Screws and Barrels

The extruder screw and barre Nan Yun producing for plastic extrusion, sheet extrusion, sindgle screw extruder, polycarbonate extrusion, rubber extruder and double screw extrusion is able to continually provide high performance on the function of melt and convey in order to meet customers' need on precision.

Screws and Barrels For Blown Film Extrusion

Categories : Screws and Barrels

The heart of blown film extrusion is screw part, the screw and barrels for blown film extrusion machine Nan Yun designed is able to deliver optimally developed polymer melt, at rates that meet the throughput target of the processor. Furthermore, the screw and barrel we designed for blown film plant or inflation machine also can have outstanding performance on melt quality, meilt temperature and gauge uniformity.

COUNTER-ROTATING TWIN-SCREW AND BARREL FOR PVC EXTRUSION

Categories : Screws and Barrels

Nan Yun is one of most experienced screw and barrel design and manufacturer in Taiwan, who are manufacturing a wide array of PVC extruder Screw and Barrel which is the essential part of PVC extrusion machine.

ABA Double Die Blown Film Extruders

Categories : Extrusion Dies / Dies Heads

The main characteristics of these kind of Extruder is available to use two or more materials to manufacture film. HSIN LONG supply customized machine specifications for different output, material, film width, film thickness. Further, it reduces the waste of material cost since it allows to add CaCo3, recycled material and color masterbatch in the middle layer for different using.

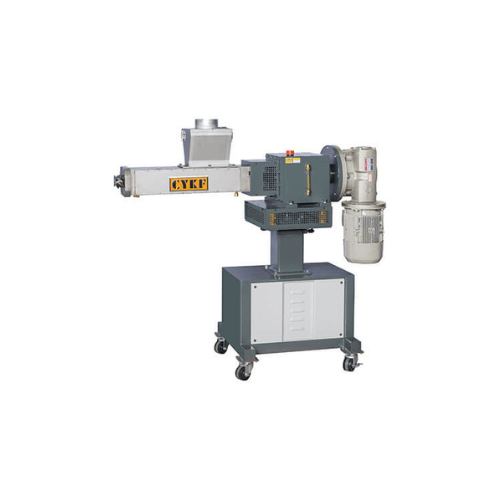

Side Feeder / Side Feeder Twin Screw

Categories : Feeders

CYKF developed its own twin screw side feeder to enable the feeding of additives and fillers, such as glass fiber, CaCO3, TiO2, Talc, fire retardant, etc. Materials in powder or pellet are all acceptable. Our rich experiences in plastic extrusion help us catch the critical design points to satisfy different production requirements.

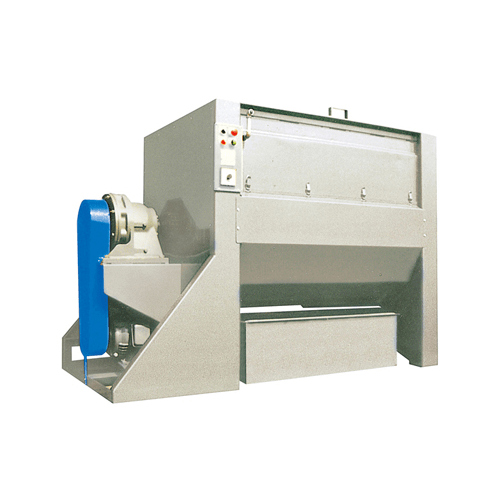

Plastic Mixer Machine

Categories : Mixers and Blenders

The pug mill is a mixer for mixing the raw material for the plastic extrusion machine. Loading capacity from 300kg & 500kg.

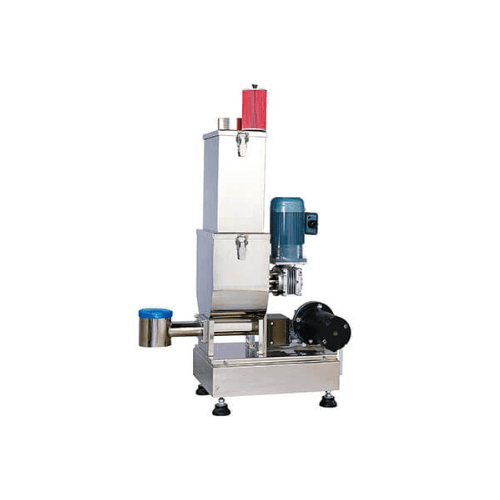

Loss-In-Weight Feeder

Categories : Feeders

Loss-in-weight feeder is a gravimetric metering device that provides continued feeding without cause batch problems. The feeder receives constant feedback from the sensor to ensure the materials are delivered in a precise amount that saves manpower successfully. CYKF provides different types of loss-in-weight feeders, including single screw, twin screw, and the models for feeding liquids. Various sizes and configurations are available to satisfy wide applications. Our team equipped with both profession and experience in the field of plastic extrusion. We provide suggestions and service for equipment integration to help customers save more money and get higher profits.