“All-in-One” Compact Dryers - SCD

Categories : Dryers and Dehumidifiers For Plastic Materials

Shini "optical" compact dryers combine the function of dehumidifying, drying and two-stage conveying into one single unit, specified for the production of "optical class" products, such as lenses, LCD backlight panel, compact discs etc. They feature honeycomb rotor for dehumidifying, ensuring continuous and constant low dew-point. Under ideal conditions, it can provide lower than -40℃ dew-point dehumidified air.

Patented Housing Desiccant Rotor Dehumidifying Dryer (DHML)

Categories : Dryers and Dehumidifiers For Plastic Materials

Patented Housing Desiccant Rotor Dehumidifying Dryer (DHML) 1. Unique design of insulated desiccant rotor system. 2. Efficient and energy saving design of exclusive rotation mechanism for the rotor & desiccant chambers. 3. Easy-load design for desiccant replacement. 4. No pneumatic valves necessary to control the air flow between areas. 5. Accurate PID temperature controller. 6. Ideally design for PET preform systems. 7. Intelligent Microprocessor Control and premium overheat protector 8. Energy saving heater and unique design for saving electricity. 9. Well designed Solid State Relay (SSR) and protective devices. 10. Obtained numerous domestic and oversea patents of Japan, the United States, Germany, Taiwan and China.

All In One Compact Dryers SCD

Categories : Dryers and Dehumidifiers For Plastic Materials

Shini "optical" compact dryers combine the function of dehumidifying, drying and two-stage conveying into one single unit, specified for the production of "optical class" products, such as lenses, LCD backlight panel, compact discs etc. They feature honeycomb rotor for dehumidifying, ensuring continuous and constant low dew-point. Under ideal conditions, it can provide lower than -40℃ dew-point dehumidified air.

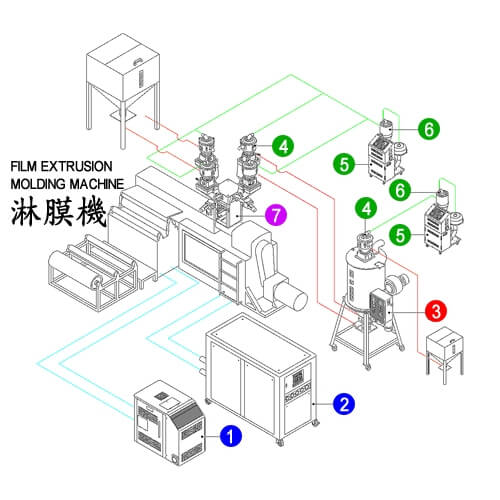

Film Extrusion Molding Machine Auxiliary Solutions

Categories : Assembly Systems

We have a wide range of auxiliary equipment for film extrusion molding mechines, like hopper dryers, dehumidifying dryers, chillers, PET crystallizers, vacuum loaders, mold temperature controllers, master-bacth feeders and auto dosing and mixing systems. Better company image Greater productivity Lower cost Better energy efficiency Less material waste and pollution during the conveying process Better working environment Less noise due to the separation of the blowers from the working place

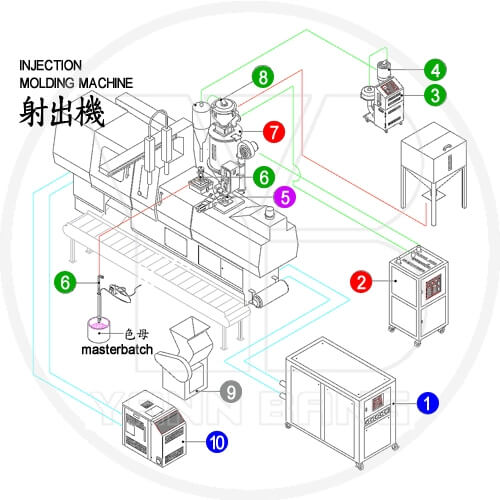

Injection Molding Machine Plastic Auxiliary Solutions

Categories : Vertical Injection Molding Machines

YANN BANG offers a wide range of auxiliary equipment specificaly for injection molding mechines, like hopper dryers, dehumidifying dryers, chillers, PET crystallizers, vacuum loaders, mold temperature controllers, master-bacth feeders and auto dosing and mixing systems. Better company image Greater productivity Lower cost Better energy efficiency Less material waste and pollution during the conveying process Better working environment Less noise due to the separation of the blowers from the working place

Dual-chamber Dehumidifying Dryer

Categories : Dryers and Dehumidifiers For Plastic Materials

With patented dual-chamber design, the unit can dehumidifying better and save more power energy for you. The model suits to the hopper dryer for large size per hour capacity.

Honeycomb Dehumidifying Dryer (DHC)

Categories : Dryers and Dehumidifiers For Plastic Materials

1. Import Honeycomb of ceramic fiber , exceed dew point below -40°C of dried air 2. Intelligent Microprocessor Control and premium overheat protector. 3. Accurate PID temperature controller. 4. Well designed Solid State Relay (SSR) and protective devices.

Mould Sweat Dehumidifiers - SMD-H

Categories : Dryers and Dehumidifiers For Plastic Materials

SMD series mould sweat dehumidifiers are designed to remove the moisture sweat from condensing on the mould surface. Forming of moisture sweat on the mould surface is due to the use of chilled water for reducing the moulding cycle time, particularly while moulding of the PET preforms. This series of machine uses honeycomb rotor to carry out dehumidifying function, which generates a dry airflow with dew point ranging from 0℃ to -10℃, and ensures the surrounding air of mould remaining in a low dew-point temperature. It provides constant low dew-point surrounding air to the mould surface all year round without being influenced by the change of seasons.

Multi-function Dehumidifying Dryer (DHC-NA)

Categories : Dryers and Dehumidifiers For Plastic Materials

Multi-function Dehumidifying Dryer (DHC-NA) Three-in-one design can dry, dehumidify, and automatically convey resins, save money. 1. Low noise to promote the quality of environment. 2. Easy to move. The unit with wheels can move anywhere for your need. 3. Designed structure to save more space for use. 4. Combine drying and dehumidification system to save energy and lower carbon emission. 5. Air filter and pipe cleaning device are easy to take out without any tool to save your time. 6. Hopper Dryer made by stainless steel with clean door for easy maintenance.

Micro Dehumidifying Dryer (DHM-SL )

Categories : Dryers and Dehumidifiers For Plastic Materials

The latest micro dehumidifying dryer uses compressed air to dry the plastic resin. The air volume generated by the air compressor is suitable for the production of small parts, such as electronics parts. The perfect grade of dryness coupled with a moderate amount of drying air, the production efficiency greatly increased. Air compressor process the air via water filtration, and the air will be compressed between pressure 5~7kg/cm² . The compressed air will then go through the molecular sieve and supply the dry air with dew point up to -40 ~ -50 ℃. During the molding process, it will fully demonstrate the perfect plastic properties. In accordance with the different types of plastic, the drying time required is also slightly different, for 2 to 6 hours. The multi-function design can dry, dehumidify, and automatically convey resins. Comparing to the regular dehumidifying dryer, it can save space and directly connect to the inlet of molding machine. It can directly convey the drying resins to production to prevent resurgence and to ensure the production complete. 1. Display the dew point detection 2. Insufficient air pressure detection 3. Built-in positive pressure conveying system 4. Overheat preventer 5. Weekly timer 6. Install high-density filter 7. With Industry 4.0 features, Ethernet and RS485 can be used to connect with other brands. 8. The controller and main body can be separated or combined to facilitate for space arrangements.

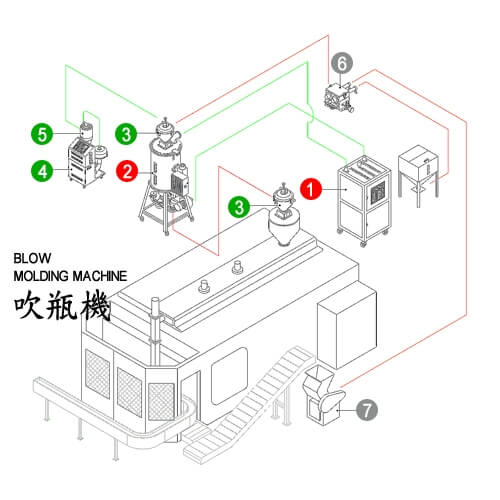

Blow Molding Machine Plastic Auxiliary Solutions

Categories : Extrusion Blow Molding Machines

For blow molding mechines, we can supply a wide variety of auxiliary equipment, e.g.: hopper dryers, dehumidifying dryers, chillers, PET crystallizers, vacuum loaders, mold temperature controllers, master-bacth feeders and auto dosing and mixing systems. Better company image Greater productivity Lower cost Better energy efficiency Less material waste and pollution during the conveying process Better working environment Less noise due to the separation of the blowers from the working place

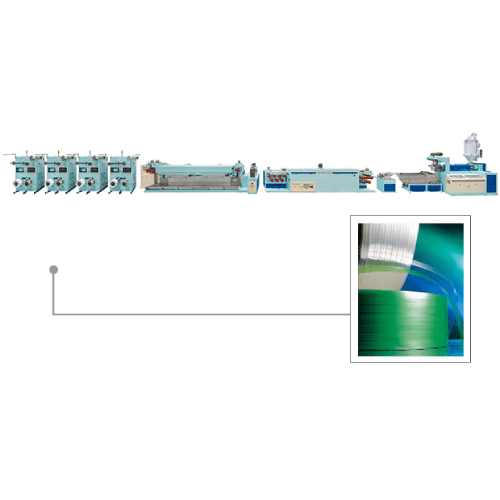

JS 237APR / JS 2310APR2 PET Heavy Duty Strapping Band Making Machine

Categories : Tape Extrusion Machines

Extruding output range: 40 - 100 kgs/hr or 80 - 220 kgs/hr. Band width: 9.5 -19mm. High precision band width +/- 0.5mm. Entire machine employs direct drive for low noise running. Gears are hardened and precision ground for quiet running performance. SACMI screw is nitrogen treated, precision ground, and stress relieved. SACMI barrel is nitrogen treated, precision ground, and stress relieved. #304 stainless steel cooling water tank. Separate adjustment for winding torque and running speed ensures uniformity of band. Stretching unit is all-gear driven with oil bath lubrication for stability, quiet running and long service life. WINDING UNIT The winding unit is driven by a DC torque motor, featuring torque adjustment. The buzzer sounds when the preset length of band is reached. Changing the gears conveniently changes the winding width. Aluminum winding rollers. Choice of 200 or 400mm core bobbin. PRE-HEAT STRETCHING UNIT The machine uses electric heating to quickly achieve high temperature. The four stretching rollers are individually driven, and heated for efficient stretching. Stretching speed is controlled by a frequency inverter for maximum stability. EMBOSSING ROLLER The embossing rollers are manufactured from SKD11 material, vacuum heat treated for superior hardness and maximum wear resistance. Embossing depth is pneumatically adjusted with indication reader for accurate reading. Separate motor drive. MAIN CONTROL PANEL The temperature for the barrel, screw, and die are separately displayed on the main control panel. Temperature can be preset. JS 2310APR2 Hydraulic screen change. JS 2310APR2 2 layer straightening operation extends heating time, ensuring the stability of bands and superior tensile strength. Hot air circulation provides for a more efficient heating solution. Equipped with a water cooling tank for upgrading cooling and stiffening performance. Outstanding dehumidifying performance ensures constant band quality. DEHUMIDIFYING DRYER The dehumidifying dryer lowers the moisture content below 0.2% to achieve the utmost performance from production materials. The dryer prevents such problems as cracking, streaking, bubbles, flow marks, poor transparency, etc., which are all caused by incompletely dry resin.