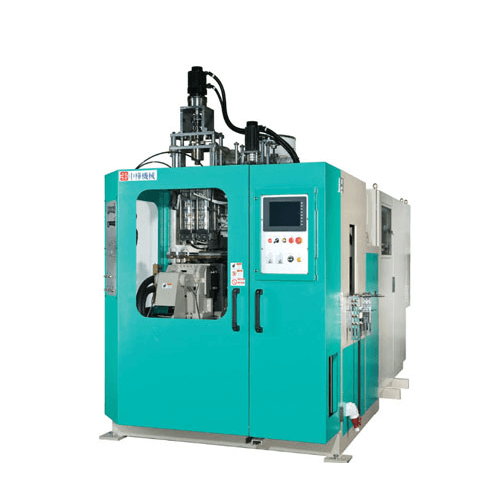

Single-Stage Injection Stretch Blow Molding Machine - ISB Series

Categories : Injection Blow Molding Machines

GF/ISB series adopts the world's most advanced single-stage injection stretch blow molding machine technology. One single machine is able to achieve high quality and efficient productivity. Compared with two-stage PET machines, GF/ISB possesses several advantages. Golfang

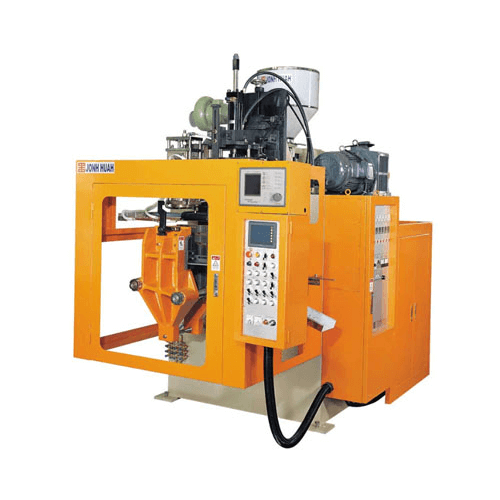

JH Series-Single Station

Categories : Automatic Blow Molding Machines

●Supply All Electric type and Hybrid type Blow Molding Machine. ●Much lower noise. ●Reduced the cost of maintenance and time. ●High stable quality of production. ●Save more then 72% energy. (to run 24 hours)

JS Series-Single Station

Categories : Automatic Blow Molding Machines

●Hydraulic type Plastic Blow Molding Machine. ●Automatic production design. ●Mold Open/Close/Move by cylinder. ●Gearbox drive extruder system. ●PLC control with Touch Screen for function, time, pressure...etc. ●Diversified parison knifes and multihead choices depend on the requirement. ●Proportional pressure hydraulic system. ●Especially for 2 liter bottle and 5 liter bottle.

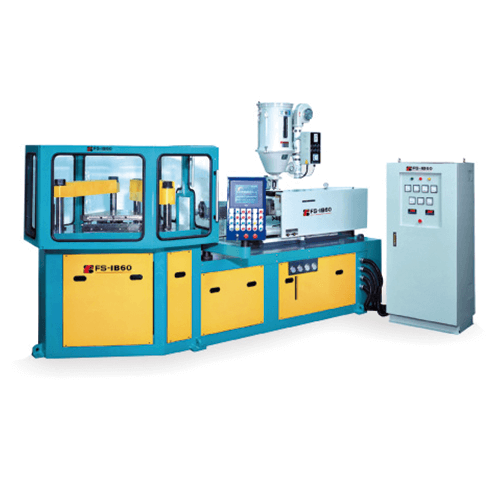

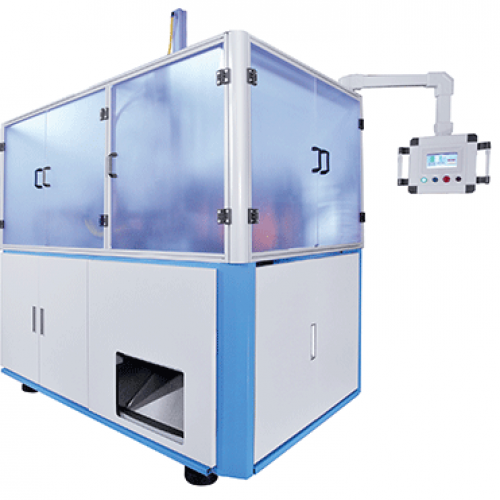

One Step Injection Blow Molding Machine-FS-IB60

Categories : Injection Blow Molding Machines

Full Shine's Injection Blow Molding Machine is the advanced machine, combining injection molding mechanism with blow molding mechanism together. This machine is suitable for processing PP, PE, PC, PS, PETG, & PMMA resins.

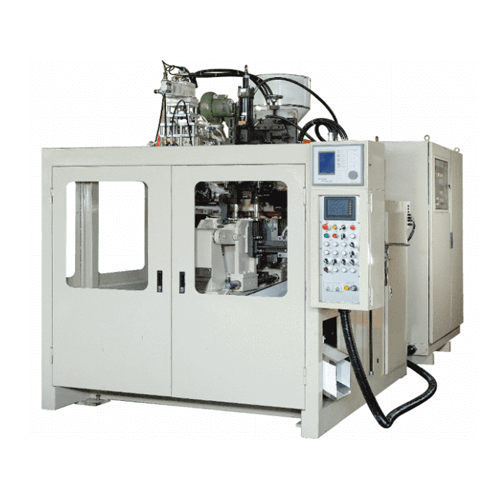

JN Series-Single Station

Categories : Automatic Blow Molding Machines

●Hydraulic type Automatic Blow Molding Machine. ●Automatic production design. ●Heavy-Duty clamping structure design. ●Mold Open/Close/Move by precision linear guide and finished bottles come out in line for next process. ●Gearbox drive extruder directly. ●Scraps centralize management. ●PLC control with Touch Screen for time, pressure, flow,...etc. ●Diversified parison knifes and multihead choices depend on the requirement. ●Energy saving system for hydraulic system.

JN Series-Double Station

Categories : Automatic Blow Molding Machines

●Hydraulic type Automatic Blow Molding Machine. ●Automatic production design. ●Heavy-Duty clamping structure design. ●Mold Open/Close/Move by precision linear guide and finished bottles come out in line for next process. ●Gearbox drive extruder directly. ●Scraps centralize management. ●PLC control with Touch Screen for time, pressure, flow,...etc. ●Diversified parison knifes and multihead choices depend on the requirement. ●Energy saving system for hydraulic system.

Semi-auto Stretching Blow Molding Machine

Categories : Automatic Blow Molding Machines

Semi-Auto Stretching - Blow Molding Machine The semi-auto reheat stretch blow molding machine includes a rotary heater and blowing unit for a 2-step process: The rotary heater unit for softening the preform The blowing unit to extend the soft preform laterally and form the product The most commonly used materials are PMMA, PS, and AS. This machine is very popular for making transparent goblets, kettles, big jars, and food storage containers.

PET Stretch Blow Molding Machine (FCP Series)

Categories : Automatic Blow Molding Machines

Grouping Brand Parts Internationalization Apply for Small Production Line Complete Online Consultation Service QR code Intelligent Management Networkable Machine (Optional)

PET Stretch Blow Molding Machine - TEM08M3

Categories : Automatic Blow Molding Machines

FEATURE Adopt the touch screen control system with 64K color and friendly PLC operation. Exclusively designed machine construction makes it convenient to combine the blow molding machine with conveyor system. The preforms are automatically arranged in order for feeding system at a single way and the dividing carrier is driven by a servo motor; this way will avoid preforms jamming, causing machine down or preforms waste. Adopt a servo control screw driving system; it is rapid, stable, clean and environmentally friendly. The preforms are fed into the heating system in a matrix mode and uniform heated by single-lamp with double-sided heating. Employ a single-lamp with double-side heating design and will save about 50% heating consumption compared with competitor method. With the temperature feedback function, temperature in the heating oven is automatically controlled by adjustment of infrared lamps to reduce prefrom crystallization problems. Specially designed heating box upgrade convenience of maintenance in changing infrared lamp and cooling ramp. The clamping mechanism is driven by a combination of servo motor and cam; this results in accurate and stable motion, low noise and minimal pollution. Utilizes the air recovery system and efficiency up to 50% so that the low-pressure air compressor will not be required. This will save equipment investment costs and energy consumption by up to 15%.