Inverter Duty Motor: TFEF Series

Categories : Motors

Higher precision motion control and speed adjustment to make the machine in automation, high production capacity purpose.

HIGH ACCURACY AUTOMATIC CUTTER TRC-350

Categories : Foaming Machinery

Automatic justitying tension control system. This system aim to a design for winding materials, thus making receipt control more steady and smooth. Excellent and stable bottomdead center accuracy. With it's specially-designed characteristic and precision processing, this machine is characterized with highly stable cutting accuracy that makes 100% of yield for finished product. Cutting depth adjustment mechanism. It's design adopts one featuring paramenter input along with the memory module that results in an easy operation. This machine which can be adjusted to full-cut or semi-cut mondel features a rapid speed in setup.

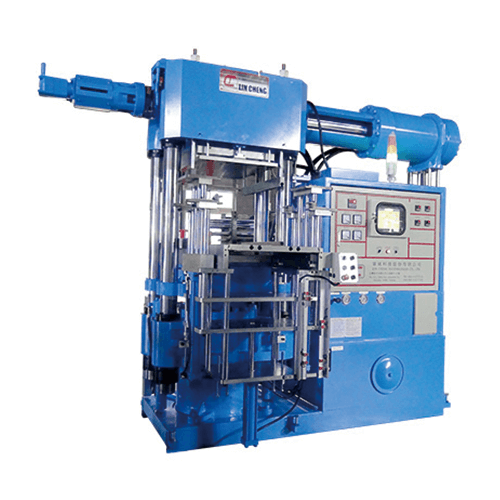

Manual Feeding Transfer Injection Molding Machine

Categories : Rubber Injection Molding Machines

Features Injection volume control High precision optical ruler is adopted for precisely calculating and controlling. Design of rotary injection board Special designs for loading/unloading functions are provided. It causes no dead material in the injection nozzle. It is easy to clean the material. It is durable and the quality is stable.

HIGH-ACCURACY ROLL-TO-ROLL AUTO FEED CUTTING MACHINE TRC-350CP

Categories : Foaming Machinery

Special Feed Mechanism: Designed for the material having different characteristics to achieve automatic machining for the soft materials. Well-Designed And Stabilized Bottom Dead-Point Accuracy: Using patented bottom dead-point mechanism exclusively developed by CHULIING to achieve +/-0.005mm of repeated positioning accuracy. High-Accuracy/High-Depth Adjusting Mechanism: Used high-accuracy mechanism to achieve fine-tune accuracy for up to 0.01mm (0.001mm is for optional). High-Efficiency Boosting Circuit: Which reduces over 30% of power consumption as compared to conventional circuit. Multi-Layer Material Flexibility: To handle over 4 rolls of materials during one machining process to achieve doubled growth of production efficiency. Unique Tension Transmission Mechanism: To effectively control the deviation tolerance during material conveying as to alleviate the production yield rate. Automatic Lubrication Mechanism: The machine uses automatic lubrication mechanism to easing the burden of daily maintenance. Waste Recovering Mechanism: After cutting, the machine will recover the waste automatically to save space while enhancing the operability.

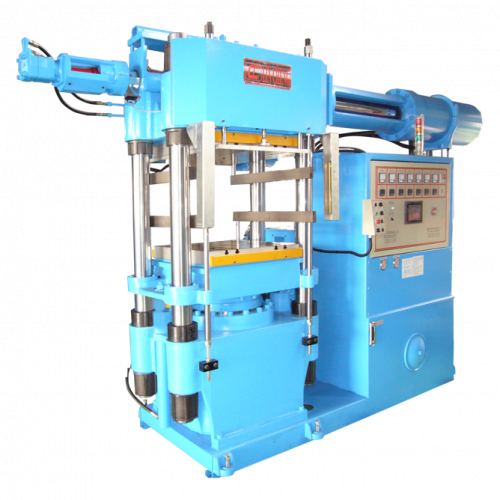

2-Layer Mold Vacuum Compression Molding Machine

Categories : Compression Molding Machines

High steel 4-column style mechanism with high precision of parallelism. Adjustable daylight accommodates different height of molds. Diversified stripping device suitable for various type of molds opening.

Magnetostrictive Displacement Sensor

Categories : Indicators and Sensors

The magnetostrictive displacement sensor is a high-precision displacement measurement sensor developed using the magnetostrictive principle. It adopts a non-contact measurement method, has a long ser vice life, strong environmental adaptability, and does not require regular calibration and maintenance; the product is an absolute output, and does not need to be reset to zero when restarted; it has the technical characteristics of high precision, high stability, high reliability and high repeatability; supports current, voltage, SSI, Modbus It is widely used in high-demand industrial occasions such as petroleum, chemical industry, steel, port, machinery and food, and is the first choice for high-precision displacement control.

HIGH-SPEED STEEL MOLD CUTTER HSP-12

Categories : Foaming Machinery

Innovative Feed Mechanism: In which, the auto up/down feed system is designed for the height of the molded material. Superb And Stabilized Dead-Point Accuracy: For which the dual-axle synchronized mechanical structure is designed to achieve higher lower dead point stability. High-Precision Depth Adjusting Mechanism: Which uses left/right synchronized fine-tune unit to achieve 0.01mm of fine-tuning accuracy. Parameter Saving Function: To name and store relevant parameters after being set. Molding Machine On-Line Function: To carry out synchronized control with other molding machine through on-line operation. Automatic Lubrication Mechanism: In which, the automatic lubrication mechanism is designed to reduce the daily maintenance work.

Up-Down Rubber Injection Molding Machine

Categories : Rubber Injection Molding Machines

Features Injection volume control High precision optical ruler is adopted for precisely calculating and controlling. Design of rotary injection board Special designs for loading/unloading functions are provided. It causes no dead material in the injection nozzle. It is easy to clean the material. It is durable and the quality is stable. Safety design A high-tech infrared safety electronic sensor and automatic warning system are adopted to monitors the status of machine in order to provide extra protection to ensure the operation safety for operators. Hydraulic system Design Hydraulic system Designed by proportional pressure and flow ratio, which is steady, quiet and low frequency of malfunction. Two shafts can be operated simultaneously.

Hydraulic Clamping Injection Molding Machine (HCV Series)

Categories : Horizontal Injection Molding Machines

• New hydraulic clamping mechanism is with integration high pressure cylinder and prefill valve at top end which is to raise up the locking pressure much faster , also fast speed for mold closing and opening . Whilst , solid mechanical design provides much stronger rigidity of mold platen and ensure the high accuracy of molding products . • Linear transducers for Clamping , Ejection and Injection strokes , accurate and easy in operation . • Adopted the high efficient Japan made servo system ( DAIKIN SUT SYSTEM) which is with pressure transducer to detect and feedback , also the encoder behind motor will calculate and provide accurate oil flow to achieve CLOSE LOOP control . SUT system can provide excellent response time ≦ 0.07sec , repeatability ≦ 1% and linearity ≦ 1% . • With diagonal dual carriage cylinders to enforce the nozzle holding force . Liner rails with ball bearings supports whole injection unit to reduce the mechanical resistant and accurate the injection control. • Digital type back pressure control. • Ion nitrided screw and barrel sets are with long working life .

HIGH-ACCURACY ROLL-TO-ROLL AUTOMATIC FEED CUTTING MACHINE TRC-350SP

Categories : Foaming Machinery

Double-Axle Synchronous Feed Mechanism: Enhances the production speed and Yield Rate through double-axle synchronous feeding. Well-Designed And Stabilized Bottom Dead-Point Accuracy: Uses the patented Bottom Dead-Point Mechanism exclusively developed by TRURAN to achieve +/-0.005mm of repeated positioning accuracy. High-Accuracy Depth Adjusting Mechanism: Uses high-accuracy mechanism to achieve 0.01mm of fine-tune accuracy (0.001mm is for optional). High-Efficiency Boosting Circuit: Reduces over 30% of power consumption as compared to conventional circuit. Photoelectric Material Flexibility: Uses as the dedicated moving system according to the material characteristics. Unique Material Moving Mechanism: High-stability servo control system is used to avoid contaminating and scratching the material. Automatic Lubrication Mechanism: The entire machine uses Automatic Lubrication Mechanism to reduce daily maintenance work. Waste Recovery Mechanism: The System will recover the waste of cutting automatically to save space, while enhancing the operability.

3RT Mold-Open Rubber Injection Molding Machine IRH-S3

Categories : Rain boot Injection Molding Machines

Mold opening design The 3RT surpasses the traditional top opening mold that can be used for the triple or four molds with the design of the opening mold and pushing out the mold in the between. The opening mold can be adjusted by the software with separate opening, separate pushing out the mold in between, continuous opening and continuous pushing out the mold in between. Injection volume control High precision optical ruler is adopted for precisely calculating and controlling. Design of rotary injection board Special designs for loading/unloading functions are provided. It causes no dead material in the injection nozzle. It is easy to clean the material. It is durable and the quality is stable. Safety design A high-tech infrared safety electronic sensor and automatic warning system are adopted to monitors the status of machine in order to provide extra protection to ensure the operation safety for operators. Hydraulic system Design Hydraulic system Designed by proportional pressure and flow ratio, which is steady, quiet and low frequency of malfunction. Two shafts can be operated simultaneously.

HIGH ACCURACY AUTOMATIC CUTTER(ROLL TO ROLL) TRC-350GP

Categories : Foaming Machinery

Automatic justifying tension control system this system aims to a design for winding materials, thus making receipt control more steady and smooth. Excellent and stable bottomdead center accuracy with its specially-designed characteristic and precision processing, this machine is characterized with highly stable cutting accuracy that makes 100% of yield for finished product. Cutting depth adjustment mechanism its design adopts one featuring parameter input along with the memory module that results in an easy operation. This machine which can be adjusted to full-cut or semi-cut model features a rapid speed in setup.