Self Contained Hopper Loaders SAL-U

Categories : Loading and Conveying Machines

SAL-U series self-contained hopper loaders are Euro design with stainless steel hopper to avoid material contamination. In addition, it has an attractive appearance, a sound-proof motor cover to reduce noise level and a top handle to enable convenient movement. Also the remote operation has been realized by using a detachable control panel.

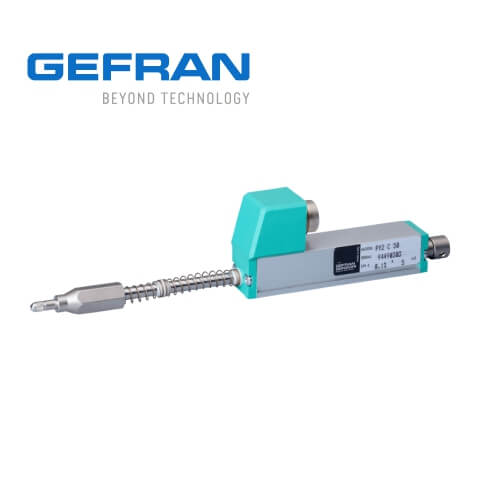

PY2_Rectilinear Displacement Transducer With Ball Tip

Categories : Indicators and Sensors

Compact. Double support for measurement rod. Side connection permits through-rod structure, guaranteeing greater overall sturdiness of the sensor. Model PY1 has a joint for greater tolerance in movement. PY2 and PY3 automatically position the head thanks to the return spring, making them the best solution for precise checks on cams or products leaving an automatic production line. ( Geotechnics, sanders, ceramic machines (thickness and planarity check), woodworking machines (thickness and planarity check )

Standard Flexible Rotogravure Printing Press(WRP-AS Series)

Categories : Rotogravure Printing Machines

In order to apply to various printing demands and output, Worldly develops a series of WRP-AS rotogravure printing machine with deliberate design. Because of the connecting with central control system, also the uncomplicated human-machine interface setting and accurate color register device, the machine can bring the beneficial result of high quality and certain output. Moreover the automatic orientating splicing device can decrease the waste material effectively to decrease the loss.

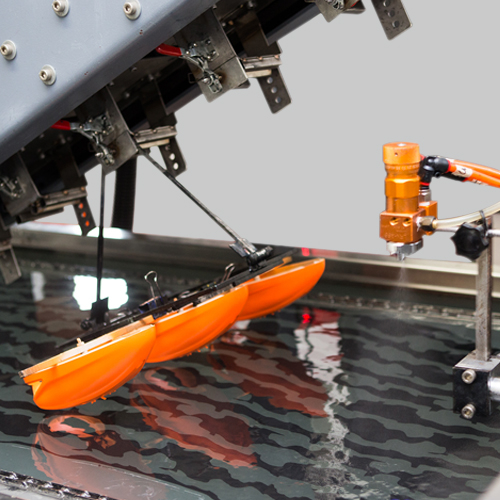

Water Transfer Printing Process

Categories : Hydrographic / Water transfer Machines

Yuan Heng Tai(YHT) Water Transfer Printing process is a method used to apply graphics such as wood grain, stone or camouflage onto substrate. The standard process is very important especially for certificate of automotive, aviation and branded products. We provide complete know-how transfer and training for WTP process based on customer's facility and product application. The approval of products relys on YHT experience and standard process.

Four Axis Industrial Robot - SR6IA

Categories : Industrial Robots

This industrial robots widely used in a variety of applications such as grabbing, handling, gluing, and splitting. Repeated positioning accuracy and dynamic response. Through the controller and software, the operation setting and management operation can be realized simply and conveniently.

High Speed Decoration Rotogravure Printing Machine(WDP-H Series)

Categories : Rotogravure Printing Machines

This model consist of five color printing units and one coating unit which is suitable for water base ink printing and apply to wide paper such as wallpaper and furniture leather and so on. Consider about cost, WORLDLY use special thermoduct with heat recycling system to promote its efficiency. In addition the blower use with infrared heating device which imported from Italy to accomplish complete drying for paper with water base ink printing. Moreover the machine drive with Japan-SUMITOMO sectional drive system. The machine approve by CE certification and produce in East Eruope.

Seaming Machine K3 Plus

Categories : Shrink Sleeve Machinery

Unwind Edge Guide System Independent Unwind, Forming and Rewind Tension Zones Frictionless Forming System Automatic Layflat Set-up Automatic Layflat Correction Direct Injection Solvent Application System Automatic Solvent Positioning System Proportional Solvent Speed Control Rewind Oscillation Fastest Set-up in the Industry

Dual-Line Analog Input Process Meter - DL Series

Categories : Indicators and Sensors

Viatran's multi-purpose, easy-to-use DL Series analog input process meters are ideal for level, flow rate, temperature, or pressure transmitter applications. They accept current and voltage signals (e.g. 4-20 mA, 0-10 V). Three of the front panel buttons can be custom-programmed for a specific operation. The analog input can be scaled to display the process in two different scales; for example, the main display could indicate level in feet and the second display could indicate the volume in gallons.

PPV Proportional Pinch Valve

Categories : Separators

Product Serial: PPV Pinch valve works in a way to open or to close a fluid path in a flexible tube by squeezing or pinching the tube. With a proportional pinch valve, the shaft that pinches the tube is driven by a stepper motor, thus that the extent of pinching can be adjusted, which indirectly controls the fluid flow rate inside the tube. The advantage of using a pinch valve is that it has no contact with the fluid, making it an ideal option for biotechnology processing, food industry, dosing system, blood process/analytical, CIP and SIP process, and biopharmaceutical equipment. Our PPV series pinch valve is driven by the PM series driver that accept either analogue ( 0-10V or 4-20mA) or digital RS485 modbus signal. What is a Proportional Pinch Valve? A Proportional Pinch Valve is a type of pinch valve that combines the characteristic and features of a pinch valve and a linear stepper motor. It is a great way to control fluid flow or fluid pressure in applications that emphasize sterile, clean, non-contact, avoid cross-contamination environment, such as Biotechnology Chemical Processing Dispensing, Filling, & Mixing Process Equipment Bioreactors Medical Devices Pharmaceuticals Life Sciences Food Processing In this article, we will start by introducing what type of proportional pinch valve KaoLu could offer, followed by the working principle, and when should you use a proportional pinch valve, and then conclude with what you should consider before making a decision on which valve to purchase. What type of Proportional Pinch Valve does KaoLu offer? KaoLu offers mainly two types of proportional pinch valve – miniature and high torque version. Miniature version: please click on photo to product brochure ,or visit https://www.genndih.com/pinch-valve/proportional-pinch-valve.html Three versions are now available: PPV-04, for tube outer diameter (O.D.) 3.5 – 4.5 mm (~0.125” to 0.188”) PPV-06, for tube O.D. 5.5 – 7 mm (~ 0.25” ) PPV-08, for tube O.D. 7 – 9 m (0.375”) The tube O.D. is flexible because we are using flexible plastic tube, and as long as the tube can fit into the insertion slot, it will be functional. The higher torque version is suitable for soft and more rigid tubing, up to durometer of 75 shore A. Please click on photo for product brochures, or visit https://www.genndih.com/pinch-valve/proportional-pinch-valve.html It is available to up 5 different sizes PPV-930-64 – tube O.D. 6 – 7 mm (~ 0.25”) PPV-930-95 – tube O.D. 9 – 10 mm (~0.375”) PPV-930-127 – tube O.D. 12 – 13.4 mm (~0.5”) PPV-930-191 – tube O.D. 18.6 – 19.6 mm(~0.75”) PPV-930-254 – tube O.D. 24.8 – 25.8 mm (~ 1”) All our proportional pinch valve can be controlled by either analogue (0-10V or 4-20mA) or digital signal. There is also an option for encoder. For the correct selection of product, please contact our product consultant. We also provides a video demo on how proportional pinch valve function, please visit and subscribe for our latest videos. https://www.youtube.com/watch?v=5z31SR9wqgk What is the Working Principle of a Proportional Pinch Valve? A proportional pinch valve combines the features and advantage of a pinch valve and a linear stepper motor. Let’s firstly introduce you the concept of these two items. Pinch Valve A pinch valve works in a way by pinching or squeezing a flexible plastic tube through a shaft that can be controlled by solenoid electromagnetic principle, by pneumatic pressure, or by a linear stepper motor. Pinch valve is especially useful in applications that does not allow valve to be in contact with the fluid inside the tube, such as chemical reagents, food, corrosive fluid…etc. A traditional pinch valve only provides full open or full closure function, and the disadvantage is that there is a flow rate drop when the tube is inserted into the pinch valve, and there is no way to control fluid flow rate. Linear Stepper Motor A linear stepper motor is a type of actuator that used the characteristic of a stepper motor to achieve linear motion. The degree in which one can control a step distance and torque is greatly dependent on the control system and the stepper motor quality and characteristics. A stepper motor is commonly used when one requires high resolution, high repeatability, and high torque. Pinch Valve + Linear Stepper Motor = Proportional Pinch Valve The combination of both provides an excellent solution for application that requires an automation on process line that requires sanitary environment and applications that require cleanliness and sterility, as well as highly accurate incremental flow or pressure regulation. This eliminating the need for multiple-valve, high-maintenance assemblies, and this single valve offers a compact, efficient solution. When should I use a Proportional Pinch Valve? KaoLu is expert in pressure and flow regulation. Please refer to the graph below: Pressure Regulation: The left had side is the control of inline pressure with a traditional on/off pinch valve. The right hand side shows the pressure control with a proportional pinch valve. In a process line that does not allow fluid to be contaminated, one could consider a proportional pinch valve to adjust the inline pressure by controlled the opening of the tube via a proportional pinch valve. With a fine step control, the pressure could be adjusted in a high resolution manner. Flow Regulation: The graph shows that the inline fluid flow rate could be regulated by a proportional pinch valve. The curve could be shift leftward with either a higher resolution stepper motor control or by adjusting zero offset of the pinch valve. With a proportional pinch valve, one can easily control (non-contacting method) the inline fluid pressure and flow rate, this offers a great advantage to many industries. What should you consider when purchasing a Proportional Pinch Valve? 1. Tube: outer diameter, material, shore A, inner tube pressure 2. Performance: resolution, repeatability, can achieve desired accurate flow or pressure control 3. Control: analogue or digital control We called it TPC. It is important to understand the characteristics of the tube you are using and the operating pressure. Sometimes, a suitable tube may not work if you have a high inner tube pressure which the pinch valve could not squeeze or pinch at all. Secondly, the performance of the proportional pinch valve should be taken into account when choosing which brand of proportional pinch valve is suitable for you. With KaoLu’s proportional pinch valve, we are able to achieve up to 40000 steps per revolution and the velocity in which the pinch shaft moves to squeeze and the torque of the motor could be calibrated easily by our customers to suit different requirements. The third important factor is control method. With our digital control method, it is possible to operate the valve half a mile away from the valve itself. We also provide RS485 holding register where the user could adjust zero offset and other parameters to fit customized solution. Please visit our product website for further information. https://www.genndih.com/pinch-valve/proportional-pinch-valve.html and remember to visit our youtube channel and subscribe for latest video updates: https://www.youtube.com/channel/UCjQ9bjuSOT_csnVA9if4_EQ/videos

Mold Temperature Controller (YBMI/YBMD)

Categories : Control Equipment

Steady controlled temperature makes plastic molding accurate in size and consistent with quality. Accurate mold temperature solves the problem of plastic flow patterns, reducing flow and weld lines, gloss appearance, record grooves effect, silver streaking, stress-whitening, warping, and etc.... P.I.D temperature controllers are used for accurate control of temperature within±1℃. Two-step-heating selector makes rapid temperature increasing possible when require thus saving time and power specially start up in the morning. Patented “Heat-insulated” design improves your safety, extend the machine’s lifetime and make maintenance more efficiently. YBMI : By oil, suit for long-term continuous operation, keep the temperature steady, no flash on tiny and thin products, and no corrosion. However, the heater may be damaged if you do not use the thermo oil correctly or change oil routinely. Recommend to choose oil-type mold temperature controller when your required temperature is 150℃ or above. YBMD : By water, heating up faster, cooling better, harmless to your mold and more economic than oil type for maintenance and cost. However, the water boiling point is low and the element of different water may occur corrosion or limescale to affect the heat exchange and products quality. Recommend to choose water-type mold temperature controller when your required temperature is 150℃ or below.

ULTRASONIC CLEANING MACHINE SINGLE TANK ULTRASONIC CLEANING MACHINE

Overview and characteristics of ultrasonic cleaning machine ※ Ultrasonic cleaning is widely used, such as electrical appliances, electronics, automobiles, industrial machinery, etc.; optical lens degreasing, removal of surface attachments and cleaning parts, using a powerful ultrasonic cleaning machine with the cleaning Engineering to improve the production efficiency and the cleaning quality and working environment by using single-slot, multi-slot, and automatic methods.

H,TC Series

Categories : Control Equipment

With thermocouple-break indication ON / OFF or proportional control selectable Heater-break indication selectable 5 alarm output modes selectable ARICO - The Best Solution Of Temperature Controller ARICO Technology and worldwide's rubber and plastic injection industry manufacturers have cultivated a long and stable co-operation relationship between us for many years. We was founded in 1987, base on sophisticated manufacturing technology, and focus on the research and development and innovation of industrial control instrument technology. We are not only good at producing customized precision Temperature Controller and related application equipment, but also provides high-quality Temperature Controller with the most convenient setting mechanism, stable quality, at a reasonable price to manufacturers in Taiwan, China, the United States, India, Argentina, Israel, Mexico, Thailand, Malaysia, Southeast Asia and other countries. In addition to accumulating and stabilizing partners for related instruments with Temperature Controller, ARICO continues to conduct research and development in order to provide more stable and efficient machine stability, just for achieving a higher efficiency and stable instrument technology level on temperature control, displacement sensing, pressure sensing, injection molding machine IoT on rubber and plastic industry.