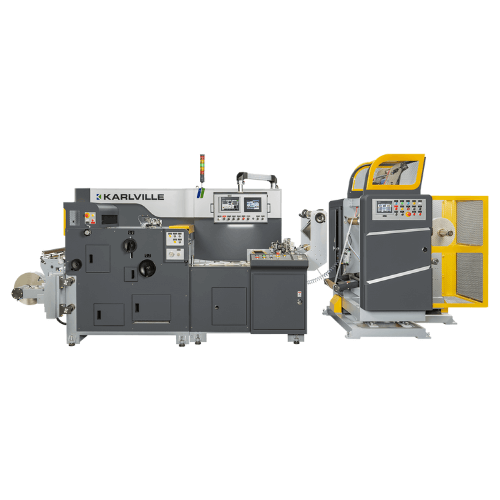

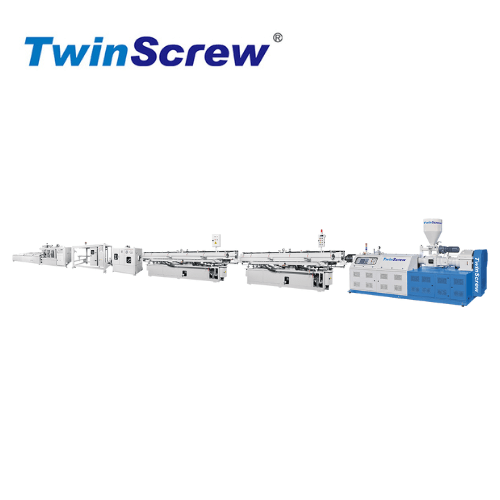

Reel to Reel Printing Line NRP-2012/8C (New Developed Model)

Categories : Flexographic Printing Machines

● Reel to Reel Printing Line is the most efficient way for the PP woven bag printing, and capable of two side printing on the bag in the one process, based on the current market demand, we are able to proide 12 colors(each side 6 colors) Reel to Reel Printing Line. ● Our Reel to Reel Printing Line provide the best printing quality with high output (up to 120 meter / minute) and only one operator required. Decreasing the printing cost to the lowest. It is the most wisdom choice for printing.

ATC990 Process Controller

Categories : Inspecting and Testing Equipment

The ATC990 with a graphical/text LCD display is a universal input process controller with advanced functionality including Trend views as well as Digital Inputs, USB and data logging options.

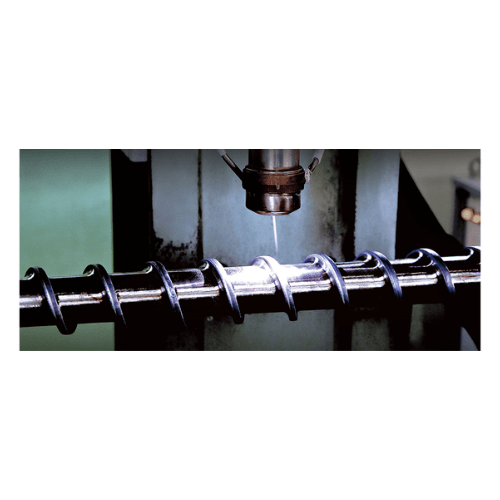

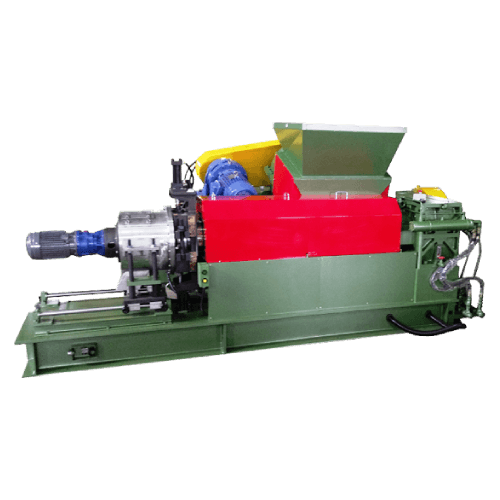

Feeder-Ruder Pellet Making Extruder

Categories : Feeders

This new model Feeder-Ruder Pellet Making Extruder usage for extruding and pellet making after Plastic or Rubber compound mixing in the Dispersion Kneader and conveying to the hopper of this machine. Pellets making method with mold Hot Face Cutting and Water ring cutting two kind.

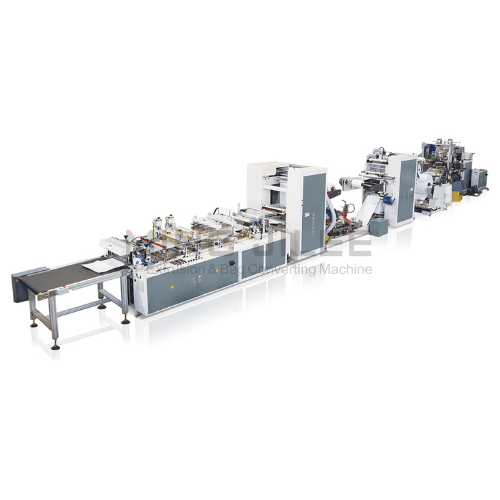

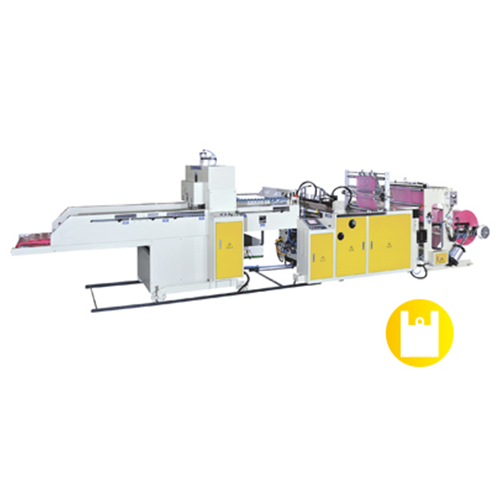

Single Line Heat Cutting T-shirt Bag Making Machine Model: CW-500P-SV1/CW-700P-SV1/CW-800P-SV1

Categories : Bag Making Machine by Applications

Single Line Heat Cutting T-shirt Bag Making Machine Model: CW-500P-SV1/CW-700P-SV1/CW-800P-SV1

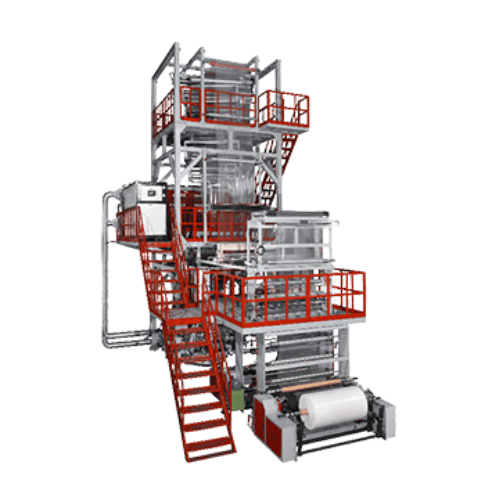

Multi-Layers Co-Extrusion Blown Film Machine

Categories : Co-Extrusion Blown Film Machines

Relying on the many years manufacturing experience of extrusion products, we understand the principle of each process of plastic blown film extrusion, we have the manufacturing capacity of blown film production line. Besides, Eterlong’s Plastic Film Blowing Machine is customized which depends on characteristics of raw materials and final applications. Before designing the products, HSIN LONG emphasizes on communications and discussion with customers in order to build the reliance with customers. Depending on the use of material, we offer from 3 layers up to 5 layers co-extrusion plastic film blowing machine. Also, the final products have all the desired properties at a significantly reduced cost.