8 Color Rotogravure Printing Machine

Categories : Rotogravure Printing Machines

For PP, OPP, PE printing and more.

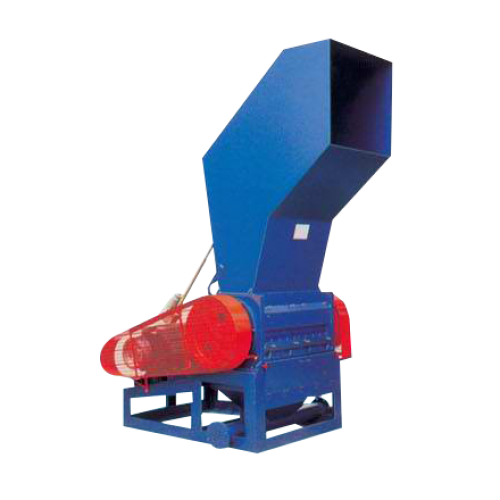

PP/PS Rigid Sheet Recycle Machine

Categories : Plastic Waste Recycling Machines

To have PP/PS Rigid sheet wastage be recycled which can be used in industrial field and make it more friendly in this environment.

5 Fold Garbage Bag Making Machine

Categories : Plastic Bag Making Machines

Flat bag style, 5 fold garbage bag making machine.

YR Multiple Embedded Rotary Injection Molding Machine Series

Categories : Vertical Injection Molding Machines

Vertical clamping with vertical injection. Rotary table oscillate 180 °, rotate back / forth for easy loading and finished parts pick out, to increase productivity. Rotary table with location pin, accurate positioning for mold alignment and automation. Robot interface capability for complete automation. Standardized wtih 2-sation function, and capable for 3-station or 4-station function & automation linkup for advanced efficiency. Standardized wtih 3-column clamp, and available for 4-column clamp upon request.

Small Blow Molding Machine

Categories : Electric Blow Molding Machines

Small-Continuous Type Blow Molding Machine This series model can produce small size containers ranging from 20mL to 10L for applications such as cosmetics, beverages, edible oil, pharmaceutical use, chemicals, housewares, and other industrial purposes. With the energy-saving system option, this machine can save up to 20% of power consumption. Some of the most common applications for small blow molding machines are: Lubricant oil bottles Laundry detergent bottles Cosmetic bottles Pesticide bottles Pharmaceutical bottles Multi-color kettles PVC cans Moreover, small blow molding machines can be customized according to the client’s needs of production: It can be a single or double station machine A visible stripe extruder unit can be added to observe liquid level It can include an auto-deflashing unit and many other features to make the machine as automatized as possible. An automatic extrusion blow molding machine is many times preferred because it leads to the reduction of manpower need which results in reduced costs, increased efficiency, and time savings for an organization.

Automatic CO-Extrusion Blow Molding machine- P Series

Categories : Horizontal Blow Molding Machines

CO-EXTRUSION BLOW MOLDING MACHINE FOR MULTI-LAYER BOTTLES – Applicable for single and double station with single to multiple die heads for producing up to SIX-LAYER CONTAINERS (2 TO 6-LAYER CO-EXTRUSION), such as chemical bottles, catchup bottles, or cosmetic bottles. Co-extrusion application allows unrelated materials with different characteristics to be combined in one parison through Full Shine special-designed die head. This combination binds different materials, such as combining high-gloss outside layer and barrier layer by an adhesive layer between them in order to achieve the perfect outcome. Co-extrusion application is the advanced technology by the leading brand: Full Shine.

DPM-The Shaft Driven Press

Categories : Rotogravure Printing Machines

DPM ( The Shaft Driven Press) The press is an economical solution for gravure printers. This is the basic model in the rotogravure class. The press is driven by shaft for the registration control. If you are looking for a shaft driven rotogravure press, this is the press for you to customize

PET Stretch Blow Molding Machine - TEM12S2

Categories : Automatic Blow Molding Machines

Blower power consumption for 1000 bottles: 2Wh Air Compressor power consumption for 1000 bottles: 6 kWh compact space Screw driven controlled by servo motor providing fast and smooth motion Single lamp bilateral centralized heating, easy controlled within 3°C and energy heating Low-pressure air compressor will NOT be required due to high-pressure recovery system. High efficient air recovery system up to 45%

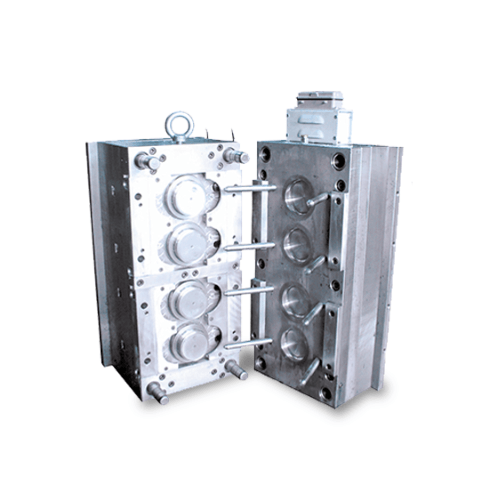

P-19

Categories : Injection Molds

Heavy Duty Profile Cutting Machine With Winding Unit

Categories : Foaming Machinery

A heavy duty type profile cutting machine, designed for cutting flexible urethane foam (polyester, polyether, polythylene) into profiled pattern.

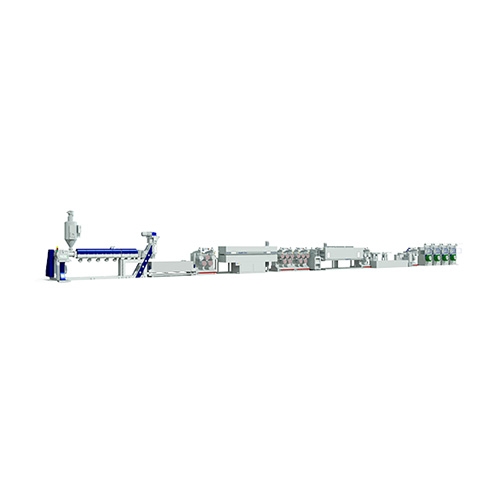

PET Strapping Band Extrusion Line (JC-SPET Series)

Categories : Tape Extrusion Machines

Our JC-SPET Series of strapping band extrusion lines utilize the latest extrusion technology to produce PET strapping bands from 100% treated PET bottle flakes. The resulting straps possess tensile and breaking strength comparable with steel bands, offering a safer, economical, environmentally-friendly solution for medium- to heavy-duty applications, such as securing bricks, tile, cotton bales, and lumber.

Extrusion Dies Lamination

Categories : Extrusion Dies / Dies Heads

EXTRUSION DIES LAMINATING DIES CFJ Width: 500 ~ 5000 mm Die lip span: 0.6 ~ 1 mm Extrusion capacity: 100 ~ 500 kg/hr Width adjustment: internal deckle system Die lip adjustment: manual or motor drive SUITABLE AVAILABLE POLYMERS INCLUDING EAA, EVA, PE, PET, PP, PS, Surlyn EXTRUSION DIES LAMINATING DIES CFC Width: 500 ~ 2500 mm Die lip span: 0.6 ~ 1 mm Extrusion capacity: 100 ~ 500 kg/hr Width adjustment: internal and external deckle, and others Die lip adjustment: manual SUITABLE AVAILABLE POLYMERS INCLUDING PE, PET, PP, PS EXTRUSION DIES WITH AUTO CONTROL Width: 500 ~ 5000 mm Finished goods thickness: 0.012~0.05µm Extrusion capacity: 100~500 kg/hr AVAILABLE POLYMERS INCLUDING BOPET, BOPP, Laminating PE

Polyamid 66 - NBE1200G30

Categories : PA(Polyamide) /Nylon

Glass fiber 30% reinforced, super high impact. Applications: Hand tools, Power tools, Gardening tools, Automobiles, motorbikes, bicycle parts and components, Spare parts of sports equipment, Electronics, Electrical cases and components, OA office components, Water supplies, Medical rehabilitation equipment.

C Type / Tie-barless Rotary Table - YC Series

Categories : Vertical Injection Molding Machines

C Type / Tie-barless Rotary Table - YC Series - C-type structure, the deformation is small. Easier for insert molding.

GENERAL TYPE BLOWN FILM MACHINE

Categories : Blown Film Extruders

Applicable raw materials: HDPE, LDPE, LLDPE, EVA High-efficiency machine with high capacity but low energy consumption High-class gear box with enforced lubrication system and oil cooler Well-designed screw and barrel provide good mixing quality Nip rolls of adjustable height

P-06

Categories : Injection Molds

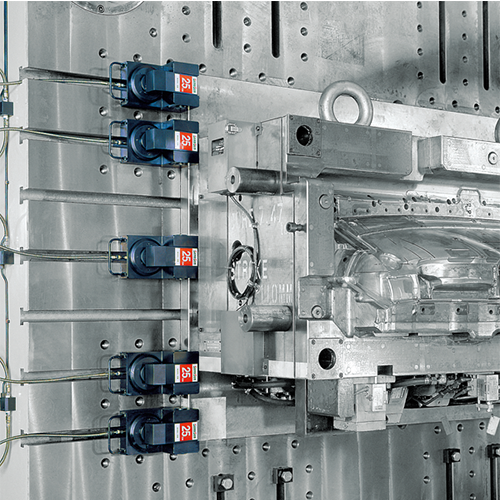

Quick Mold Change System

Categories : Mold Changing Systems

It is an era for making high frequency mold change with multiple patterns and small quantity. In order to save time for the mold change and ensure the safety of the operation, it is just in time to apply Quick Mold Change System. SAFETY FUNCTION OF SYSTEM Each hydraulic circuit has the function of check and avoiding oil leaking. This system can add pressure automatically when the pressure reduction. Each hydraulic circuit has the function of inspection pressure and can be interlocked with the machine. It adopts the intersecting direction to clamp the mold. There are several functions to avoid operation error.