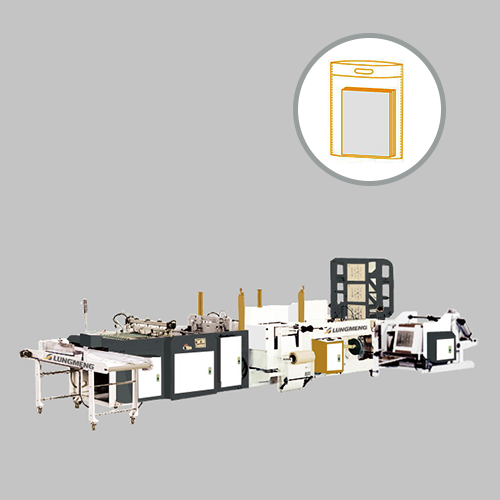

Classification : Converting System

Country: Taiwan

Phone: 886-6-232-1126

Fax: 886-6-203-1178

Contact Person: Kelly Kao

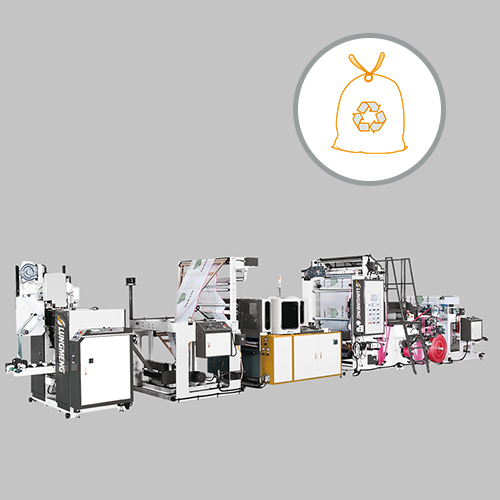

This garbage bag on roll making machine can produce garbage bags with different types of materials such as HDPE, LDPE, PP and more. The garbage bag thickness ranges from 0.008 mm to 0.07 mm, and the maximum production rate reaches 100 meters per minute.

-

Advanced Design

New developed concept of continuous turn around theorem and special design of free-loop film tensioning device allow for sealing tightness, supporting even the thinnest gauge material. -

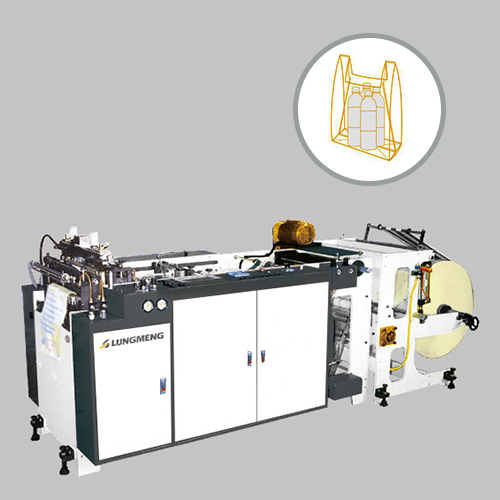

Single and Double - Track Production

Flat seal for c folding and 2-up servo driven system supports high-speed turn around work, ensures film running even, makes operation & maintenance easy. -

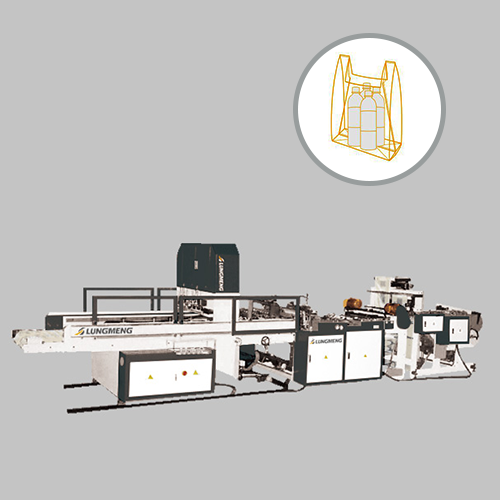

High Productivity

Max. Speed 150 M/Min., material suitable for HDPE, LDPE, LLDPE, PP & recycled. -

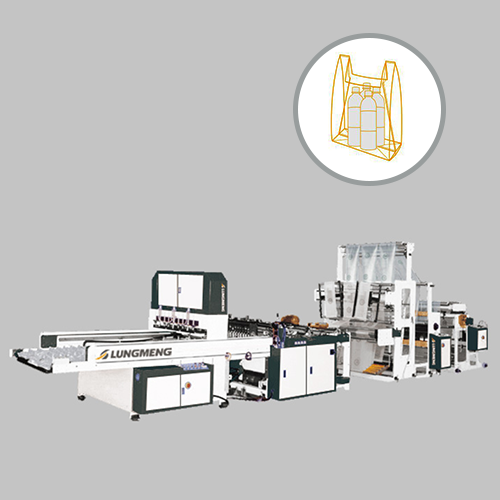

Synchronized Rewinding & Labeling

The fully automatic high speed four spindle roll winder includes the highly efficient auto labeling device to synchronized the products' surface to be posted by the label. -

Surface Unwinder

Surface winder is designed for one single flat and 2 star seal rolls of different roll diameter. -

Operator - Friendly Controller

User interface panel control micro - processor , provides bag parameter setting and diagnostic information without stopping production. -

Jumbo roller in-line with hot slitting device.

| Model: | TAD800D1-S |

| Mother Film Width (mm): | 750 |

| Mother Film Dia. (mm): | 1000 |

| Thickness of Film (mm): | 0.008 - 0.07 |

| Finished Production (mm): | 300 x 2 or 700 x 1 |

| Finished Production Roll Dia.(mm): | 130 |

| Max. Production Speed (M/ min): | 100 |