Shredder Integrated Recycling Machine | GEOR-DING-

Shredder Integrated recycling machine Features: -Can handle large heavy materials or thin-film materials 0:50 -Automatic backfllush screen changer,Reduce the screen changing labor cost 1:03 -Side Feeding Twin Screw design

Cutter Compactor Plastic Recycling Machine (KRIEGER Series) | GENIUS

The KRIEGER series cutter compactor plastic recycling machine integrates crushing, extruding and pelletizing in one machine. A proprietary designed cutter compactor can compact the density of fluffy plastic film to flakes. It helps to increase the efficiency of extruder. After compactor, the materials are extruded to Genius patented universal joint pelletizing system. The universal joint pelletizing system can automatically adjust the distance when cutting the polymer to pellets. Significantly reduces manual adjustment error rates. After cooling, these pellets are sent to centrifugal dryer to remove moisture. A vibrator at next step removes powders or oversized pellets. Finally, recycled pellets can be reused in different fields, for example, blow film or injection molding industries. / Key Features of Cutter Compactor Plastic Recycling Machine / Energy cost saves up to 20% Only 1~2 operators are needed to operate the pp recycling machine. High-speed rotation operation makes the fluffy material compact. Simultaneous material dewatering. Triple cooling sections – air cooling system, compactor body water cooling system, and water spraying system. The temperature control is convenient, and the temperature of the crushing barrel is controlled in a stable manner. Provide customized recycling, sorting, feeding, degassing, filtering, granulating to storage and packaging systems.

Vertical Injection Molding Machine Rotary Table | TAIWAN KINKI

MACHINERY IN THE VIDEO: Vertical Injection Molding Machine -Rotary Table KT 300R 3S FEATURES: -Vertical mold clamping and injection, small footprint, and high degree of precision. This machine is ideal for the injection of medium and small products with inclusions. -The Dual-cylinder injection system offers high injecting pressure for fast operation, making this injection machine your best choice for the production of thin items. -Direct-pressure mold clamp allows even injection force, and the relatively low pressure means maximum precision and an incredibly smooth cycle of operation. -Choose a platen or a rotary plate in accordance with the type of products to be injected, in order to achieve the best possible in feed and injection effects. -This machine offers a wide range of programmable functions including automatic inclusion, extraction, and fully-automatic production.

Food Packaging Solutions | AI SHIN Interview

At the recent TAIPEI PACK exhibition, PRM Media Channel had an interview with AI SHIN MACHINE CO., LTD. to discuss about the current situations in the packaging industry, upgrade in the service of the company due to current pandemic, also the machinery showcased. AI SHIN is famous for its Automatic Filling & Sealing Packing Machines. The company specialized in manufacturing high speed packing machines for food, filling and sealing liquid cups such as yogurt, juice and water cups. Let us know your opinion and the inquiry in the comment section. Stay tuned for the forthcoming interview videos and remember to subscribe to our social media channels for the similar videos!~ MAIN PRODUCTS/SERVICES OF AI SHIN: Automatic Filling Machine, Automatic Sealing Machine, Rotary Type Filling Machine, Filling & Sealing Machine, Bag Sealing Machines, Sealing & Packing Machines, Semi-automatic Sealer, Rotary Type Sealing Machine, Fully Automatic Box Filing & Sealing Machine for Butter, Capping Machine for Butter, Yogurt Packaging Machine, Pudding Filling & Sealing Machine, Frozen Food Filling & Sealing Machine, Cup/Bowl Instant Noodle Packing Machine, Packing Machinery, Cap Sealing Machine, Jam Cap Sealing Machine, Butter Filling/Sealing Machine, Cup Filling Sealing Machine ***

Food Processing Machine Solutions | HUNDRED MACHINERY

Since 1996, Hundred Machinery Co., Ltd. has been the professional automatic encrusting machine manufacturer in Taiwan. PRM Media Channel had an interview at the recent TAIPEI PACK and had a chance to introduces the companies automatic food processing machinery lines. Let us know your opinion and the inquiry in the comment section. Stay tuned for the forthcoming interview videos and remember to subscribe to our social media channels for similar videos!~ MAIN PRODUCTS/SERVICES OF HUNDRED MACHINERY:

Mold Cart | FORWELL

Mold Cart - Mold Cart System-Forwell Features -Fully automated die or mold changing - High precision die or mold placement - Increased safety and efficiency - Can serve multiple production lines at once - Multiple layout configurations System Introduction : Forwell's Die / Mold Cart System provides automatic die or mold changes for a range of different machines, such as plastic injection molding machines, plastic extrusion machines and press machines. This Die / Mold Cart system offers very fast, efficient and safe die and mold changes, using an advanced cart on rails system. Conventional die or mold changes can often take over an hour, but with the Die / Mold Cart System, die or mold changes are automatically completed in just a fraction of the time. Using this system, all procedures from die transfer and changing, to positioning and clamping is carried out by this system, resulting in extremely accurate die or mold changes. As the Die / Mold Cart System offers very precise die or mold changes, many operational issues can be avoided such as locking screws breaking when hand tightened, and incorrect mold alignment resulting in damage to the mold or production equipment. The Die / Mold Cart System also massively increases safety and efficiency, by allowing for automatic operations and making it feasible to perform many small batch production runs. Another great feature of this system is that it can be configured to specific user needs, different production facilities and serve multiple production lines at once.

Circular Loom Machine - 6 Shuttle Circular Looms | HAO YU

Introducing 6 Shuttle Circular Looms Machine from HAO YU. With HAO YU HY7-m6SCL six shuttles circular loom is designed with 6 shuttles to perform tubular weaving at high speed up to 180 RPM which is the highest technology in this woven bag equipment field in Asia. It reaches outputs up to 140 meters per hour. In case warp and weft breaks (finished), the machine stops automatically, An auto compensation system is also equipped to prevent the machine from empty weaving, it is an advanced circular loom specially designed to meet the stringent productivity requirements of today. The circular looms equipped with European inverter and high quality components. HAO YU is applying patent in Taiwan, China, India, and other countries. 【Machine Features】 Low spare part consumption & easy maintenance Energy saving nearly 50% over conventional models Large weft yarn insertion capacity up to 1080 PPM(max) Flat yarn applicable weaving denier from 500-1200(standard) Large weft yarn carriage capacity up to 115mm(max) Equipped with European inverter for main motor Lubrication-free for shuttle & cam 【Optional Accessories】 Gusseting device Both sides heat slitting device and additional fabric winder Center unfold device with heat slitting device and extra large unwinder for cement bag industry 【ABOUT HAO YU】 Hao Yu has been dedicated to manufacturing PP/PE/PET woven bag machinery and whole-plant equipment since its establishment in 1980. Enhancing present machinery and developing new models are Hao Yu’s objectives in order to improve the efficiency, product quality, and profitability for their customers.

Rotary Table Injection Molding Machine | TAIWAN KINKI

MACHINERY IN THE VIDEO: Rotary Table Injection Molding Machine with Full Auto System from TAIWAN KINKI (TKC) [TAIWAN KINKI LINES OF BUSINESS] Production of vertical plastic injection molding machines. Design of automatic injection molding machinery. Turn-key plants for accessories and peripherals for injection machinery. Injection mold design and manufacturing. Electrodeposition, powder coating, baking enamel, and leather treatment. Agency of the vertical injection machine and Zinc alloy coating. [APPLICATIONS] Especially suitable to manufacture Automobile Parts [TAIWAN KINKI (TKC) BACKGROUND] TKC had over 40 years of experience in Vertical Injection Molding Machine manufacturing. The company offers a full series of vertical injection molding machine portfolios including Standard, Slide, and Rotary table models. TKC also offers mold design and a full auto system for customer's products.

Brief Intro of Plastic Recycling & Pelletizing Machine | GEORDING

【Product Line】 Plastic recycling machine Compounding machine Dyeing & Pelletizing Automatic batch weighing and mixing system Washing line Rubbing drying machine Powerful crusher Shredder Plastic flat board extruder Refuse derived fuel (RDF) 【Company Intro】 GEORDING MACHINERY CO., LTD. has dedicated to innovating their machines with superior features which can process various plastic materials, such as PA, PET, ABS, TPU, Calcium Carbonate and even PE foam. By keeping developing and improving their technology, GEORDING has become one of the leaders of the extruder supplier as well.

Mold Cart System Co-Ordinated with AGV for Plastic Injection Molding - Industry 4.0 | SANDSUN

Mold Cart System Co-Ordinated with AGV for Plastic Injection Molding - Industry 4.0 | SANDSUN Introducing automatic injection molding mold change carts system from SANDSUN in Taiwan, which is a leading global customized die and mold change cart system manufacturer. Please refer to the link above to learn about SANDSUN's detailed designs on the mold cart system, including functional advantages such as Hook Type, Motor Roller Type, Real Case, and Electric Mold Trolly. SANDSUN has been providing high quality, secure and efficient injection molding machine mold change cart systems to India, South Korea, Thailand, the United States, Vietnam, Malaysia, Mexico, Brazil, Russia, and many other countries at a reasonable and affordable price for many years. Thus, SANDSUN earned a good reputation in mold change systems and die change systems around the world. Features of die/mold cart system : Shorten the operation time of mold change. Auto position checking of mold changer moving. Automatically check the stroke of mold open, arrival, and positioning in the process of moving. Device for preventing mold sliding. Die / Mold Cart System co-ordinate with AGV : This video was shot at Chung Yuan Christian University in Taoyuan, Taiwan. The content is the collaboration between the automatic mold cart system and the automated guided vehicle (AGC). The combination of two high-tech devices effectively increases industrial production efficiency and achieves industry 4.0 goals. # SANDSUN Die Cart System Mold Cart System AGC Automated Guided Vehicle Fourth Industrial Revolution Industry 4.0 PRM Media Channel Hizli Kalip Degistirme Sistemleri Enjeksiyon Makinesi Kalip Degistirme

Plastic Recycling Machine, Repro-Flex | POLYSTAR

【Machine Features】 The one-step plastic pelletizing machine, Repro-Flex, combine cutting, extrusion, and pelletizing into one compact and efficient pelletizer line. The cutter-compactor of the plastic pelletizing machine prepares the plastic waste (PE plastic film and PP plastic film waste) into an ideal condition for the extrusion process and feeds the plastic waste directly into the extruder. This integrated system does not require a separate crusher, and therefore, eliminates the problem of inconsistent feeding, reduces space and labor costs, and has lower energy consumption. Simple in Design. Flexible in Operation. POLYSTAR is able to customize its machines regarding customers’ needs. How this pelletizing system works: 1. Feeding a. By belt conveyor Feeding of scraps is easy and automatically controlled depending on the amount of material input. b. By Nip roller Film-on-rolls can be fed at the same time. 2. Cutting and compacting The cutter compactor integrated cuts, dries, and compacts the material which enables a fast and stable feeding from the compactor directly into the extruder. 3. Degassing system The two-zone degassing can process plastic film with larger printed areas. 4. Filtration Screen change with a dual channel system for non-stop operation that also prevents plastic material from leaking. 5. Pelletization Water-ring pelletizing system, also known as hot die face pelletizing, the plastic comes from the recycling extruder and is directly cut by the rotating knives attached to the surface of the die head. 6. Final Product Round-shaped recycled pellets are produced and cooled inside the water ring immediately. 【Company Intro】 Headquartered in Taiwan, POLYSTAR has focused on the user-friendliness of its machines through continuous re-engineering, making recycling extremely “Simple” for its users – Easy operation and maintenance is what makes POLYSTAR the No.1 selling recycling machine today. Over the past 32 years, more than thousands of POLYSTAR recycling machines have helped worldwide plastic producers to reprocess their post-industrial (in-house) waste back into high-quality pellets in a simple and easy way.

WEI MENG | WMD Onion Bag Making Machine

Our Double Needle Bar Raschel Machine is the perfect solution for businesses that need to produce high-quality, high-speed packing sacks. With a working width of 170 inches and gauges of 2 - 6 needles per inch, this machine can produce a variety of nets for different purposes. It is also ideal for producing onion bag machines, special wide nets, and double-layered nets. This machine is equipped with a high-speed warp supply system that ensures that your nets are produced quickly and efficiently. It also has a number of features that make it easy to use, including a user-friendly control panel and an automatic yarn tensioning system. If you are looking for a high-quality, high-speed Double Needle Bar Raschel Machine, then our machine is the perfect choice for you. Contact us today to learn more about our machines and how they can help your business. Double Needle Bar Raschel Machine is specially designed for onion bag and double layer nets making. This machine is applicable Yarn is HDPE flat yarn and monofilaments. Standard gauges machine 2 - 6 needle per inch, Maximum performance of the machine can up to 600rpm.

High Speed 2 Lines Coreless Bag on Roll Trash Bag Making Machine | CHAO WEI

High Speed Fully Automatic 2 Lines Coreless Bag on Roll Trash Bag Making Machine | CHAO WEI, TAIWAN [DESCRIPTION of the Machine] ⚡️Special for two lines perforating coreless bottom and star sealing bags on roll. ⚡️In-line triangle folding device for star sealing bags. ⚡️E.P.C. (Edge Position Control) for the film at correct position. ⚡️Japan made servo motors & servo drivers control bag length precisely and high speed production, reducing electric consumption. ⚡️Bag length & production speed can be changed easily from touch screen. ⚡️German made photocell-SICK for accurate printing mark. ⚡️Automatic lift up reel unwinder with air shaft, reducing the number of employees. ⚡️Automatic tension control with AC motor and inverter system for jumbo diameter film roll. ⚡️Two lines automatic roll changing system.

2024 CHINAPLAS Interview | JANDI’S

We are here with Tony from JANDI’S at the CHINAPLAS. JANDI’S INDUSTRIAL CO., LTD. is committed to developing blown film machines combined with bag-making, printing, and recycling machines. They obtained more than 30 patents for plastic machinery in China and Taiwan. With the concept of plastic reduction raising, JANDI’S proposes an idea about green innovation. The company develops JIT series integrated plastic bag-making machines that are 100% suitable with biodegradable and compost materials such as PBAT and PLA. Moreover, JANDI’S added the automatic packaging part to JIT series.

Full Electric Co-EBM with visi strip (4 head double station) | CM-90.55FVH2D | Chia Ming

CM-FE90.55FVH2D Full Electric Co-Extrusion Blow Molding Machine - Continue extrusion with horizontal movement and toggle clamping. Fully automatic and highly efficient production. -------------------------------------------------- Why Go Full-Electric? ► Energy savings 20%~70% ► Precise and more efficiency ► No hydraulic, less noise, no oil leakage ► Easy maintenance -------------------------------------------------- / Key Features / ★ All-electrics (Fully servo motor driven) ★ Servo Drive Die Head Nodding System ★ Full Electric Parison Control System ★ Crank Type Servo Drive Carriage Movement ★ Visi Strip function ★ Auto deflashing device ★ Backhoff, Germany and Keyence, Japan control system -------------------------------------------------- / Other Features / ★ Equipped with robot arm (2D Gripper) ★ Post cooling ★ Auto loading system ★ Residue conveyor to crusher ★ Built by standard components, i.e. Beckhoff, Festo, SMC, Toshiba, Tokimec, Schneider, ABB, Omron, ensuring straightforward maintenance at lower cost and global spare parts availability -------------------------------------------------- / Optional equipment or function/ ????Support the “Industrial” internet of things. (More info, please contact.) -------------------------------------------------- / Application/ Jerrycan/ Food packaging/ drinks/ detergents/ reagents/ cosmetics/ medicines/ engine oil bottles/ lubricants/ jars/ home products/ car parts/ decoration parts...

Quick Die Change System | FORWELL

Forwell’s Quick Die Change System is an automatic die changing system that can be specifically designed for hydraulic and mechanical power presses and press production lines. This system automates the die changing process and provides increased speed, efficiency and productivity to a workshop. The Quick Die Change System not only reduces die change time, but also promotes diverse small batch production runs and streamlines production management.

Bag on Roll Making Machine | COSMO

COSMO has many years of experience in bag making machines. We are still willing to have much more improvement and all the consumers are satisfied with the quality of machines offered to you. 【Machine Features】 2 lines coreless star sealed bag on roll making machine Oscillation film feeding & sealing system for stability and high out put Automatically reel changing system High production efficiency to save manpower and time Servo motor, as standard attachment, makes it easy to adjust the bag length and the production speed Computer control over the entire process From film roll to final bag, non-stop, one process flow Automatically stop when running out of film/ film feeding blocks or bags jam/ color scanning misses 【Company Introduction】 COSMO Machinery Co., Ltd. established in March 2001, is well-known for Taiwan manufacturing plastic bag making machinery with servo driving systems. The product from COSMO has the servo motor as standard attachment, makes it easy to adjust the bag length and the production speed, computer control over the entire process, component self-testing function available, high production efficiency to save manpower and time. Up to now, COSMO products are extensively exported to 100 countries spreading all over the world.

UHS Turret Slitter Rewinder - UHS-TR | WEBCONTROL

UHS Turret slitter rewinder The UHS-TR model is a proven fully automatic slitter rewinder, offered with many options to fulfill even the most demanding applications: - Cutting-edge slitting systems - Reliable auto cut and transfer - Advanced tension control - Combined with progressive differential winding technology - Precision and capacity at an affordable cost. - UHS-TR a must addition to any plant requiring quality Automatic knife positioning down to 25 mm slit width, double turret unwind, automated finished roll unloading systems are some of the available options to increase productivity, quality and decreasing operator influenced down time. Materials to be processed: Plastic film, paper and laminates Thickness range: -Rigid films: 10 – 200 micron -Soft films: 12 – 300 micron Machine Specification - SLIT UHS TURRET: -Web width:1300 / 1600 mm max -Unwind roll diameter: 1000 mm -Unwind roll weight: 1500 kg -Unwind roll cores: 3” and 6” I.D. -Finished roll diameter: 610 mm max -Finished roll cores: 3” and 6” I.D. -Slit width: 50 mm and up -Machine speed max: 600 m/min (depending on material type/quality) -Winding tension: 0.5 pli to 2.5 pli (11 - 45 kg) standard

Quick Mold Change System|Sistema cambio rápido moldes|быстрый mold изменение системы|SANDSUN

Learn more about the Quick Mold Change Systems : https://bit.ly/37ST04V Sistema de cambio rápido de moldes, быстрый mold изменение системы, السريع تغيير النظام العفن produced by SANDSUN Introduction of our Quick Mold Change System : It is an era for making high frequency mold changes with multiple patterns and small quantity. In order to save time for the mold change and ensure the safety of the operation, it is just in time to apply Quick Mold Change System. Sandsun safety function of Quick Mold Change System : ✔️Each hydraulic circuit has the function of checking and avoiding oil leaking. ✔️This system can add pressure automatically when the pressure reduction. ✔️Each hydraulic circuit has the function of inspection pressure and can be interlocked with the machine. ✔️It adopts the intersecting direction to clamp the mold. ✔️There are several functions to avoid operation error. Explanation of video content : Mold Change less than 2 minutes on 1300T injection molding machine 0:00 Quick mold change less than 2 minutes on injection machine 0:19 Pre-load the mold on the cart 0:23 Mold move out 0:36 Mold arrive in the position, and the cart start to switch position 0:49 Mold cart arrive in position 0:55 Injection machine adjust the stroke for mold automatically 1:04 Mold move in 1:21 Hook back to original point, door close automatically 1:28 Mold close, clamps lock the mold automatically 1:39 Protection rods rise, cart start to move 1:49 Cart back to mold hanging area, finish mold change

Vertical Injection Molding Machine - KT 300 | TAIWAN KINKI

FEATURES: 1.Vertical mold clamping and injection, small footprint, and high degree of precision. Our Vertical Injection Moulding Machine is ideal for the injection of medium and small products with inclusions. 2. Direct-pressure mold clamp allows even injection force, and the relatively low pressure means maximum precision and an incredibly smooth cycle of operation. 3.KT-300 Vertical Plastic Injection Molding Machine offers a wide range of programmable functions including automatic inclusion, extraction, and fully-automatic production. 4. Dual-cylinder injection system offers high injecting pressure for fast operation, making this injection machine your best choice for the production of thin items. 5. Choose a platen or a rotary plate in accordance with the type of products to be injected, in order to achieve the best possible in feed and injection effects. 6. There are also many other control systems that facilitate flexible production and keep costs low while maximizing precision.

Two Functioned Bags on Roll Making Machine:SR(2)MR(1)-1000-OS-2T-R4S | COSMO

Fully Automatic High Speed Two Functioned Single Line & Two Lines Core-less Garbage Bags on Roll Making Machine Machine Model : SR(2)MR(1)-1000-OS-2T-R4S Machine Name:PHENIX • Core-less bags on roll • star sealing bags / Bottom sealing bags with V, C, N, M shape • Shuttle sealing & feeding system • Four shafts re-wind system

All-Servo Drive T Shirt Bag On Roll Bag Making Machine ft. Swing Type Feeding System | PLAS ALLIANCE

T Shirt Bag Bag On Roll with core auto insert system - 32RTWDFA-VR-2 Plas Alliance has a variety of plastic bag on roll machines for customers to choose, and is committed to innovation and research and development. So far, it has developed a variety of bag making machines for various bag formats. 【T-Shirt Bag On Roll Making Machine Features】 High speed Continue feeding system available in 200/250/300rpm systems. Tension-less sealing avoids sealing line pull & elongation for high-speed production. Rotary Die cut by Magnetic cylinder with simple die cut blade exchange. Inverter controlled feeding matching main machine speed for easy operation without manual adjustment. Support to work for Jumbo film slitting into two separate roll with post gusset in line system by Option (or model : 36RTWDFA-VR+SLG2) Equipped with LCD touch panel, easy to operate Switch control to exchange bag making process without adjustment Bag re-wind in roll , paper CORE insert in line automatic End of Film, core auto STOP 【Machine Available System】 Tension-less sealing T shirt bag on roll Flat bag on roll S type bag on roll 【Company Intro】 “PAL- Working with you to create all types of bag making automation solutions!” Like the first companies in 1988 to create the first bottom seal bag machine started, and since then, we have been studying bag machine design, manufacturing, innovation and change with the bag, we have always kept up to date technology, continue to explore, develop more labor-saving, cost-saving bag machinery, to provide customers with a complete bag packaging solutions, growing up with customers, a business partner to create the pinnacle!

Water Transfer Printing Film and Equipment Manufacturer | YUAN HENG TAI-

Semi Automatic Hydro Dipping Machine with Lay film, Auto Spray Activator, and Production Arm. A powerful combination of all necessary important processes for WTP processing. From the very beginning laying, and the following activator spraying to the final dipping stage, done the main WTP process with only one button. This machine includes dipping tank, auto film layer and auto spray system. The combination of these 3 components not only makes WTP even simple, but more important– stable quality to the final product. The system can memorize multiple sets of different processes. This dipping machine is perfect for large product and medium quantities of production/day.

Solventless Laminating Machine (LM SF1300T) | WEBCONTROL

Webcontrol develops innovative solventless laminators with driven coating system and automatic turret unwind & rewind for high efficiency, consistent tension & minimum waste during roll changes.

2024 CHINAPLAS Interview | King Plus

They are the manufacturer of blown film machines. In the past thirty-five years, Han King has relentlessly accumulated vast experience, from manufacturing mono-layer machines to two-layer, three-layer, and five-layer machines. We develop and produce our rotary die, embossing device, 360-degree oscillating haul-off, internal bubble cooling system, automatic air ring, and other blown film machine components.

PP Woven Bag Fully Automatic Liner Inserting-Bag Top Hemming Conversion Line | BOTHEVEN

【MAIN FEATURE】 All in one multi-functional machine - Flexible Usage for various type of PP woven bag Processing on the same machine. Available for PP woven bags: ● With liner Inserting-Cutting-Sewing and bag top hemming process ● With Cutting-Sewing and Bag Top Hemming Process Only (Without Liner Inserting) ● With Liner Inserting-Cutting-Sewing Only (Without Bag Top Hemming process) Cutting-Sewing Process only (Without Liner Inserting & Without Bag Top Hemming) Saving Manpower, Space and Saving Cultivated Training for Skilled Manual Operation to the Maximum. Producing Finished Bags with Conformed & unified quality with stable performance Experiencing Clean Process of Bag Top Hemming, largely Reducing Hang-Touching on the bag top area. Highly synchronized machine for Easy Setup and quick bag size changeover. A Total-Solution Machine for PP woven bags with Final Products Applicable in a Big Variety Market. 【COMPANY INTRO】 Botheven Machinery Industrial Co., Ltd, (Since 1984), has accumulated more than 30 years of technical experience & know-how in the planning design, manufacturing, sales and service of PP/HDPE Woven Bag Making Machines in Taiwan. Our equipment has been sold worldwide with assured quality, stable performance and reliable after-sales services. We can build machinery according to customers' requirement; also provide cost-down solution for customers.

Corporate Image Video – Plastic Mixing Machine | AVALONG

AVALONG Corporate Image Video – Plastic Mixing Machine, Cold Mixing Machine, Pulveriser System , Automatic Weighing System, Complete Turnkey Plant AVALONG has been established in Taiwan since 1977. Plastic industry in Taiwan has grown rapidly since then. We design and develop high quality and efficiency High – Speed Mixer, Vertical Cooler, Horizontal Cooler and Semi- Automatic Conveying System suitable for PVC plastic raw materials, chemical materials, cosmetic, food, glass, ferrite, etc.

Quick mold change system|QMCS|for Injection molding|Sistemas de cambio rápido del molde|FORWELL

Forwell has been a pioneer of Quick Mold Change Systems for many years. With over 20 years of experience in developing these systems they can offer you the best for your molding operations. These fully customizable Quick Mold Change Systems drastically minimize setup times, maximize efficiency and increase safety. Forwell’s Quick Mold Change System can be designed to fit almost any injection molding machine and mold casting machine to allow for quicker mold change times, resulting in shorter machine down time and increased productivity. This system uses a special mold clamp that does not require a cut out on the mold, increasing its application versatility and allowing it to be used with a large number of different molds. Quick Mold Change Systems can rapidly transform your workshop, allowing for easy changeover for small batches, reduced labor costs and reduced stock holding. Coupling this system with a Mold Cart System will allow for fully automatic mold changing, further increasing the efficiency and productivity of your manufacturing operations. When installing a Quick Mold Change System for your injection molding and mold casting operations there are a number of direct and indirect benefits. Review the following table to see an overview of all of these benefits. Indirect Benefits Die Standardization Press Standardization Increased Safety Improved Working Environment Increased Competitiveness Direct Benefits Reduction in Die Change Time Efficient Small Batch Runs Reduced Stock Handling Higher Productivity and Quality Reduction in Labor Costs

High Speed T Shirt Bag Making Machine|PLAS ALLIANCE

T Shirt Bag Bag On Roll with core auto insert system - 32RTWDFA-VR-2 Plas Alliance has a variety of plastic bag on roll machines for customers to choose, and is committed to innovation and research and development. So far, it has developed a variety of bag making machines for various bag formats. 【T-Shirt Bag On Roll Making Machine Features】 High speed Continue feeding system available in 200/250/300rpm systems. Tension-less sealing avoids sealing line pull & elongation for high-speed production. Rotary Die cut by Magnetic cylinder with simple die cut blade exchange. Inverter controlled feeding matching main machine speed for easy operation without manual adjustment. Support to work for Jumbo film slitting into two separate roll with post gusset in line system by Option (or model : 36RTWDFA-VR+SLG2) Equipped with LCD touch panel, easy to operate Switch control to exchange bag making process without adjustment Bag re-wind in roll , paper CORE insert in line automatic End of Film, core auto STOP 【Machine Available System】 Tension-less sealing T shirt bag on roll Flat bag on roll S type bag on roll 【Company Intro】 “PAL- Working with you to create all types of bag making automation solutions!” Like the first companies in 1988 to create the first bottom seal bag machine started, and since then, we have been studying bag machine design, manufacturing, innovation and change with the bag, we have always kept up to date technology, continue to explore, develop more labor-saving, cost-saving bag machinery, to provide customers with a complete bag packaging solutions, growing up with customers, a business partner to create the pinnacle!

Sheet Cutting Machine | YICHEEN

Description: Friendly interface, PLC computer touch-panel screen control system. Non-hydraulic design, no pollution, low noise, best for using in dustless room. Servo motor control feeding (for EVA sheet cutting tolerance +/-1mm). Modulating control for tension control, it keeps cutting stable. Anti-static PU roller drive for reducing scrape happened. Optional devices: Shaftless unwind stand (electrical left/right moving), EPC (Edge Position Controller), Slitter, Punching device (electrical left/right moving), Automatic stacker, Static eliminating device,

KT Series Injection Molding Machine (ROTARY TABLE) | TAIWAN KINKI

KT Series Injection Molding Machine Vertical mold clamping and injection, small footprint and high degree of precision. This machine is ideal for injection of medium and small products with inclusions. Dual-cylinder injection system offers high injecting pressure for fast operation, making this injection machine your best choice for production of thin items. Direct-pressure mold clamp allows even injection force, and the relatively low pressure means maximum precision and an incredibly smooth cycle of operation. Choose a platen or a rotary plate in accordance with the type of products to be injected, in order to achieve the best possible in feed and injection effects. This machine offers a wide range of programmable functions including automatic inclusion, extraction and fully-automatic production. There are also many other control systems that facilitate flexible production and keep costs low while maximizing precision.

Quick Mold Change | FORWELL

Quick Mold Change - Quick Mold Change System-forwell-qmcs-en-Forwell Features • Decreased mold change time • Fully customizable to fit a wide range of machines • Safer operations • Reduced labor costs • Easy changeover for small batch runs System Introduction : Forwell has been a pioneer of Quick Mold Change Systems for many years. With over 20 years of experience in developing these systems they can offer you the best for your molding operations. These fully customizable Quick Mold Change Systems drastically minimize setup times, maximize efficiency and increase safety. Forwell’s Quick Mold Change System can be designed to fit almost any injection molding machine and mold casting machine to allow for quicker mold change times, resulting in shorter machine down time and increased productivity. This system uses a special mold clamp that does not require a cut out on the mold, increasing its application versatility and allowing it to be used with a large number of different molds. Quick Mold Change Systems can rapidly transform your workshop, allowing for easy changeover for small batches, reduced labor costs and reduced stock holding. Coupling this system with a Mold Cart System will allow for fully automatic mold changing, further increasing the efficiency and productivity of your manufacturing operations.

FSL-TR series Turret Rewind Slitting Machine | HCI

HCI’s newly launched FSL-TR1300 turret rewind slitting machine is designed for automatic slitting and rewinding operations, with automatic splicing and roll changing, stand-by paper core auto positioning, finished roll pusher and unloading device to increase productivity and reduce the operation down time. The HMI operating system equipped with a color touch screen provides easy-to-learn operations and memory of operating parameters, which makes the product quality stable.

Quick Die Change | FORWELL

Quick Die Change - Quick Die Change System-qdcs-en-Forwell Features : • Decreased die change time • Designed for hydraulic and pneumatic presses • Increased efficiency • Reduced labor costs • Safer operations System Introduction : Forwell’s Quick Die Change System is an automatic die changing system that can be specifically designed for hydraulic and mechanical power presses and press production lines. This system automates the die changing process and provides increased speed, efficiency and productivity to a workshop. The Quick Die Change System not only reduces die change time, but also promotes diverse small batch production runs and streamlines production management. Quick Die Change Systems are becoming a standard for large manufacturers as they not only increase production efficiency, but also improve the overall working environment. The Automatic Die Change System can be built specifically for your machining requirements and will drastically reduce machine idle time during die changes, boosting your competitiveness. There are also a number of indirect benefits of installing a Quick Die Change System for your hydraulic and mechanical type press machines. Firstly, automated operations reduce labor expenses, but also reduce workshop accidents and the physical stresses on operators, making them more productive. Secondly, all dies can be changed without any modification allowing for the use of standardized die and press equipment, saving costs. Lastly, multiple presses can share a single Quick Die Change System, further economizing on costs and resulting in higher efficiency and productivity.

Bottle Grade PET Bottle Washing Line | BoReTech

MACHINERY LINE IN THE VIDEO: Bottle-to-Bottle Grade PET Bottle Washing Line from BoReTech. The line is mainly used for PET bottle-to-bottle projects (FDA Approval), which recycles post-consumer PET bottles into rPET flakes. The regenerative PET flakes conform to the quality index requirements of downstream food packaging and are used for bottle blowing and packaging which can directly contact food after pelletizing and SSP processes in the late stage. HIGHLIGHTS Solutions for diversification of input PET bottle bales. Automatic de-baling technology, reduces labor, a strong bale breaking ability for high-density PET bottle bales. Patent technology for PVC label removal. Patented Pre-washing and hot washing process to ensure the cleanliness of rPET flakes. Integrated technology and capability for automatic sorting machine and PET bottle recycling line. The hot washing process reduces impurities content to achieve food-grade index. Stable and reliable quality of rPET flakes, online inspection to ensure the stability of rPET flakes. Completed online water recycling treatment system for pre-washing, hot-washing, and rinsing. Low operation breakdown, production management guidance service for the customers. FOOD GRADE PET BOTTLE RECYCLING PROCESS De-baling➜Metal Removal➜Label Removal➜Metal Removal➜Bottle Pre-washing➜Optical Bottle Sorting➜Manual Sorting➜Crushing➜Dust Removal➜FlotationHot washing➜Friction Washing➜Rinsing➜Flushing Washing➜Drying➜Dust Removal➜Optical Flakes Sorting➜Blending➜Online Inspection➜Packing FOLLOW PRM ON: PRM YouTube:https://www.youtube.com/c/PRMTaiwan PRM Facebook: https://www.facebook.com/PRMMediaChannel PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan/ #BoReTech #PRMMediaChannel #PETrecycling #PETwashingLine #BottleToBottleRecycling #PRMTAIWAN #Plastics #Rubber #Industry #Internationalmarket #Export #machinery #PET #PETbottle #Recycling

6 Cavities Automatic Injection Heading Machine | BONMART-

Double transferring rollers design. Stopless roller adjustment design. Plate wheel outer finetune mechanism Quick release ink rollers. Printing wheel clean system (200 mm dischargeable) Sleeve Printing Plate wheel pre-register mechanisim.

Plastic Bag Making Machine | WorldSteel

Suitable for a range of shapes folds and pockets, interlinking with other equipment to be able to make even more types of bags for easy exchange. Pattern types include: punching equipment for round holes, butterfly holes, utilizes handheld punching equipment for accuracy and can produce perforations for letter and packaging tear off strips. Using a vertical up and down heat sealing system and supersonic sealing line device. Provide extra parts for improved production accuracy and quality, including EPC edge sensor, servo motor to drive the machinery and an automatic conveyor to get your finished products to the packing section as soon as possible. Suitable for already perforated and/or folded films. 【Company Introduction】 World Steel Machinery Company is dedicated to making technological innovations and manufacturing packaging machines.They have the best engineering crew in the industry to provide total solutions which include design, customization and development. If you are looking for machines that produce, flower sleeves, diaper bags, book sleeves, self adhesive bags, handle bags, sandwich bags or more, then World Steel is the best choice for you.

T-Shirt Bag on Roll Making Machine | COSMO

COSMO has many years of experience in bag making machines. We are still willing to have much more improvement and all the consumers are satisfied with the quality of machines offered to you. 【Machine Features】 2 lines T-shirt bag on roll making machine High production efficiency to save men power and time Computer control over the entire process From film roll to final bag, once process flow Servo motor, as standard attachment, makes it easy to adjust the bag length and production speed Automatic film feeding, coordination free from tension adjustment Oscillation film feeding system for stability and high out put Automatically stop when running out of film/ film feeding blocks or bags jam/ color scanning misses Automatically core changing system Punch system on magnetic roller 【Company Introduction】 COSMO Machinery Co., Ltd. established in March 2001, is well-known for Taiwan manufacturing plastic bag making machinery with servo driving systems. The product from COSMO has the servo motor as standard attachment, makes it easy to adjust the bag length and the production speed, computer control over the entire process, component self-testing function available, high production efficiency to save manpower and time. Up to now, COSMO products are extensively exported to 100 countries spreading all over the world.

Bio Resin Bag Making Line - JIT Series | JANDI’S

JANDI'S INDUSTRIAL CO., LTD. is committed to developing blown film machines combined with bag making, printing, and recycling machines. Until 2018, they obtained more than 30 patents of plastic machinery in China and Taiwan. With the concept of plastic reduction raising, JANDI'S proposes an idea about green innovation. The company develops JIT series integrated plastic bag making machines that are 100% suitable with biodegradable and compost materials such as PBAT and PLA. Moreover, JANDI'S added the automatic packaging part to JIT series.

Fully Automatic Coreless Bottom Sealed Bags On Roll Making Machine | CHAO WEI

【Machine Spec & Features】 Bottom Sealed Bags On Roll Making Machine (Coreless) Film width: 600 mm / Thickness: 15 micron E.P.C Control & Rollers Device (E+L, German made) Length: 750 mm x Speed: 135 Pcs/Min Production Line Speed: 100M/Min Servo Driven Shuttle Type Sealing & Perforating Unit Two Sets Triangle Folders For Making Finished Roll With Small Width Machine Maintains High Speed Production By 4 Sets Rewinding Shafts While Producing Small Quantity Of Bags Per Roll 【Company Introduction】 Chao Wei Plastic Machinery is an advanced manufacturer of plastic bag making machine with more than 35 years of experience with ISO 9001 & CE certificates in Taiwan. One of the reasons for the excellence of Chao Wei’s machines is our dedication to research and development.

Plastic Recycling & Pelletizing Machine | GEORDING

【Product Line】 Plastic recycling machine Compounding machine Dyeing & Pelletizing Automatic batch weighing and mixing system Washing line Rubbing drying machine Powerful crusher Shredder Plastic flat board extruder Refuse derived fuel (RDF) 【Company Intro】 GEORDING MACHINERY CO., LTD. has dedicated to innovating their machines with superior features which can process various plastic materials, such as PA, PET, ABS, TPU, Calcium Carbonate and even PE foam. By keeping developing and improving their technology, GEORDING has become one of the leaders of the extruder supplier as well.

Rubber & Silicon lnjection Molding Machines | LONG CHANG

Long Chang is manufacturing the series of Rubber & Silicon injection Molding Machines, and Heated Compression Molding Machines etc. 【Machine Series】 Silicone Injection Molding Machine Rubber Injection Molding Machine Horizontal Automatic Rubber & Silicone Injection Molding Machine Single Body / Twin Body Vacuum Oil Hydraulic Compression Molding Machine Vacuum Rubber Oil Seal Hydraulic Compression Molding Machine Single Body / Twin Body Die-Moving & Ejection Compression Molding Machine Four Columns Type Oil Hydraulic Press EVA Foam Tire / Single Body Double Color Of Automatic Oil Hydraulic Compression Molding Machine 【Company Introduction】 Long Chang Mechanical lndustrial Co., Ltd. was established in 1971, under the leadership of president Huang Chin-Huo with the idea of "always be loyal to the obligation, give more than enough thought to operate the business" and demands "making the perfection more perfect" to be the target.

Slitting Machine (HS-Compact) | WEBCONTROL

The SLIT-HSC series slitter is new compact type to save the working space. From the unwind side, the web is guided middle to the main machine, easy access to the slitting section and eliminates dust collection/hazarded steps. The slitter comes standard with razor cutters and groove roller configuration. A shear cutter system is offered as option for paper and other pressure sensitive materials. The machine uses three AC Vector Drives and has automatic tension on unwind and rewind controlled through easy-to-use PLC & MNI touch screen. Friction rings are used on rewind shafts to ensure the production of quality slit rolls when the film thickness varies.

CI Flexo Printing Machine - RPM1208-CI | ROTOFLEXO

MACHINERY IN THE VIDEO: CI Flexo Printing Machine - RPM1208-CI | ROTOFLEXO - 8 colors central impression flexo printing machine - High precision stainless-steel impression drum imported from Italy - Automatic water temperature control system - High precision gear transmission system - Closed chamber doctor blade system - Automatic tension, edge, and web guide control - High speed forward and reverse printing desk motion - High precision ball screw designs for key components - Motorised horizontal and longitudinal registration system - Electric heat/drying system - CNC desk position control

Complete Set of Mixing Metering & Conveying Equipment | CHIAO WEI

【Machine Features】 A mixing system is a process of mixing raw plastic materials in particles or powders to manufacture piping and tubing structures. It is a part of the plastic extrusion process. It involves the pre-mixing of multiple additives, which is performed in an efficient manner. Mixing System is commonly used in manufacturing water pipes, plastic floors, wall panels, plastic floor tiles, wires, cables, plastic steel doors, windows, to name a few. Suitable for filling small amounts of additive. A semi-automatic operation system that saves labor and times, lowers production costs while upgrading throughput by 20%. With material storing function. No powder leakage during delivery. A mixing and delivery system that meets environmental protection requirements. The flow guide plate is a special design, featuring uniform mixing, high speed, superior dispersion and energy saving. Exclusively designed material outlet port can be set according to customer's material types. Another benefit is its fast material outfeed with residuals.(Patented design). The tank invertor is a stainless steel construction, polished to upgrade material missing efficiency and reduce electricity consumption. The steel base is a one-piece fabrication and equipped with anti-vibration pads, providing smooth and stable running. 【Company Intro】 "CHIAO WEI MECHANIC CO., LTD" founded in 1987 and a professional manufacturer of Hi-speed mixer, Blending machine & those ancillary equipments etc. Although we have established about twenty years, our staffs were continued and guided by principle of innovating, persuing the excellence & hard-working etc., Especially, the scientic-technology will be upgraded gradually as well as human life be diversified day by day. Since, our company has focused on new products R/D and manufactured hi-eff, automation, low noise & low pollution products. And we have contributed trivial efforts to make capability advances for professional.

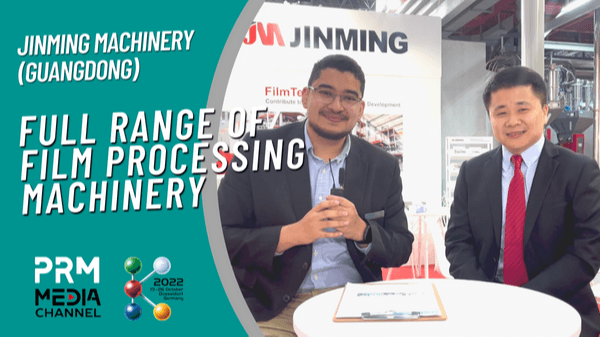

Full Range of Film Processing Machinery at K 2022 | JINMING

PRM was pleased to have a short interview with Simeon Wang, Vice President of Jinming Machinery, at K 2022. By interviewing with Mr. Wang, we have obtained the information about MDOPE solution, which was launched in recent years, to enable the stretch of the film manufactured from its machine. Moreover, Mr. Wang has expressed how Jinming solved the clients’ problems by its automatic technology during the pandemic. In the meanwhile, he also shared his observation of sustainability and expectation of the market in the post-pandemic era.

Plastic Thermoforming Machine - Fruit Container Box Machine | CHUDONG

Plastic Thermoforming Machine for Fruit Container Box - RMD 800from CHUDONG MACHINERY European design, intelligent control, lightweight. Convenient mold change, quick, suitable for smaller quantities and diverse production line manufacturing. High rate of movement, low failure rate, reducing the costs associated with machine errors. Innovative intelligent system, which gives the operator an easy to use interactive interface which reduces the opportunity for human error. Remote obstacle monitoring and instantaneous data processing allow rapid problem correction. High-precision cutting technology, allowing high-speed control, low machinery wear, and exceptional cutting performance. Adjustable, automatic stacking technology, which remembers your last production needs. Applications: Disposable Sushi box, egg tray, Various types of lids, Cooked food coverings, Strawberry box, Salad box, Plastic containers, Transparent salad containers, Fruit box, Vegetable box, Fresh fruit packaging, All types of food packaging, Takeout box, Instant noodle bowl, Lunch box, and so on

Plastic Continuous Thermoforming Machine - Automatic Cup Lids Machine | CHUDONG

Continuous Plastic Thermoforming Machine For Cup Lids | SL-1220A from CHUDONG MACHINERY High-rigidity design of machine bed: Integral casting design combined with high-tension steel plate structure offers steady and low noise operation. 4-column high-rigidity guide-rod mechanism: Guide-rods are made of top-grade steel, offering high repetitivity of mold clamping in combination with the 4-column mold structure for steady forming. Servo chain feeding system: Japanese chain operated by servo-controller ensures exact precision of high-speed feeding. Precision Temperature Control System: Independent temperature control with the respective settings for each temperature zone uses SSR with PID calculus for controlling the temperature, combined with high-speed transmission and control, offers precision adjustment, and is convenient for elevated yield. Upper and Lower Heating Oven: German-made ceramic heater, temperature accuracy can be controlled very well. Automatic Lubrication System: Automatic oil feed for slide parts, eliminating any failure resulting from insufficient lubrication. Applications: Disposable Sushi box, egg tray, Various types of lids, Cooked food coverings, Strawberry box, Salad box, Plastic containers, Transparent salad containers, Fruit box, Vegetable box, Fresh fruit packaging, All types of food packaging, Takeout box, Instant noodle bowl, Lunch box, and so on