CHINAPLAS 2021 Organizer Interview | PRM Media Channel

Recently despite many exhibitions that have been canceled or postponed, CHINAPLAS 2021 successfully made the event to be held on time, April 13th to 16th, 2021. In this manner, PRM Media Channel has conducted an online interview with Ms. Ada Leung, the General Manager of Adsale Exhibition Services Ltd., the organizer of CHINAPLAS. Ms. Ada Leung sincerely replied to our questions about this special event at a special time due to the pandemic. She also shared very useful information about the forthcoming CHINAPLAS 2021 including the focus of the exhibition, online activities for the visitors who cannot attend the exhibition, future plan of CHINAPLAS through digitalization and hybrid exhibition model. Let's take a look at the interview video to learn more, and let us know your opinions and questions.

High Speed Slitting Machine - S2A Series | YICHEEN

YICHEEN is a professional equipment supplier that specializes in soft-material cutting technology, including die cutting, sheet cutting, slitting and laminating. Since 1979 we have been supplying soft material cutting machinery. This has now transformed into state of the art high-precision customized cutting equipment, which meets worldwide standards and guidelines.

Multi-Circuit Electric Screw Drive Injection Molding Machine | CLF

Product Name: Multi-Circuit Electric Screw Drive Injection Molding Machine - CLF CLF's Products: ⚫Via continuous challenging high-end injection machinery, CLF has success- fully invented the multi-circuit plastic injection machines, horizontal injection molding Machine, servo-driven hydraulic fully closed-loop controlled injection machine, multi-color/multi- resin injection molding machine, and etc. ⚫With our strength of machinery diversity, we could provide our customers the scheme of installment of whole factory buildings to achieve perfection of techniques and produc- tion capacity, and finally help them save the cost and shorten the investment cycle.

2024 CHINAPLAS Interview | ARBURG

I'm honor to meet Dr. Christoph Schumacher, the vice president Global Marketing from Arburg. Let's hear about what's his thoughts on Chinaplas! And their new type machine launched in China.

Plastic Inflation Machine | KANG CHYAU

Plastic Inflation Machine - Twin Head HDPE Plastic Inflation Machine-Kang Chyau Specializes in Plastic Inflation Machine. Since its founding in 1988 Kang Chyau Industry has worked constantly to bring out new and innovative Plastic Inflation Machine products and offer customers a wide range of choices. After more than a decade of work our products are now sold in 62 countries around the globe, a true measure of our success in the Plastic Inflation Machine market.

Sustainable Innovation of Blown Film Machine | KUNG HSING

The latest innovation of Three Layer Blown Film Machine is featured with 3 in 1 Gap Winder that combines Surface Type, Contact Drive Type and Gap Winding. We are pleased to invite Kung Hsing Machinery to share the insight of the Blow Film Industry with us, which includes application, ESG and the effect of geopolitic to the economy. 【Product Features】 ● Five layers co-extrusion blown film line ● Φ300 mm Die : Production output 600 kg / hr ● Gain in weight gravimetric dosing unit ( Italy made) ● Profile measurement & auto thickness control (Auto Air Ring-Height Adjustable, High Efficiency Cooling and High Output Rate, Germany made) ● IBC computer control system (U.S.A Made) ● Horizontal oscillating take-up unit ● 3 in 1 Gap winder ( Surface type, Contact Drive Type and Gap Winding) 【Video Outline】 0:00 Welcome to K 2022 0:24 Introduction of Kung Hsing Machinery 0:53 Highlights of Kung Hsing at K 2022 1:54 Applications of KS Blown Film Machines 2:34 Upgrade of Three Layer Blown Film Machine 5:38 Strategy and Implementation to ESG 6:51 Customer Oriented Service 7:54 Advantages of Taiwanese Supply Chain 8:54 Occurrences affect Global Market 10:04 Development Trends of KS Blown Film Machine 11:07 More information on PRM B2

Injection Molding Machine | CLF

Injection Molding Machine - Chuan Lih Fa Specializes in injection molding machine, CHUAN LIH FA MACHINERY WORKS CO., LTD. was founded in 1966, backed up with 40 years manufacturing injection molding machine, multi color injection molding machine, All electric molding machine, plastic injection molding machine, plastic injection mold, injection molding machine manufacturer experience. CLF Supply maximum injection machine machine all over the world. Precisely productive equipments and rigidly productive procedures have providing customers with satisfied multi color injection molding machine, All electric molding machine, plastic injection molding machine, plastic injection mold, injection molding machine manufacturer quality to help them getting most profit.

Bag on Roll Making Machine | COSMO

COSMO has many years of experience in bag making machines. We are still willing to have much more improvement and all the consumers are satisfied with the quality of machines offered to you. 【Machine Features】 2 lines coreless star sealed bag on roll making machine Oscillation film feeding & sealing system for stability and high out put Automatically reel changing system High production efficiency to save manpower and time Servo motor, as standard attachment, makes it easy to adjust the bag length and the production speed Computer control over the entire process From film roll to final bag, non-stop, one process flow Automatically stop when running out of film/ film feeding blocks or bags jam/ color scanning misses 【Company Introduction】 COSMO Machinery Co., Ltd. established in March 2001, is well-known for Taiwan manufacturing plastic bag making machinery with servo driving systems. The product from COSMO has the servo motor as standard attachment, makes it easy to adjust the bag length and the production speed, computer control over the entire process, component self-testing function available, high production efficiency to save manpower and time. Up to now, COSMO products are extensively exported to 100 countries spreading all over the world.

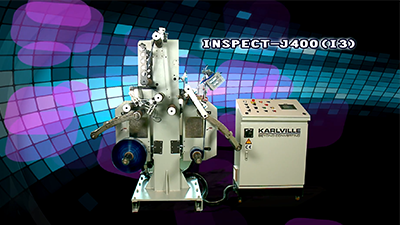

Inspection Machine | WEBCONTROL

Webcontrol Machinery Corp.- Manufacturer of inspection machine and more. More information about inspection machine: 1.Inspection Rewinding Machine- INSPECT-J300 2.Doctoring Rewinder Machine- INSPECT-H300/H400/H500 Webcontrol Machinery Corp has been specializing in manufacture of inspection machine since 1988. Webcontrol ceaselessly develop new machine to extend production line for meeting various needs of customers. In additions, we constantly improve our inspection machine with new technology, and innovate to enhances its performance, efficiency and reducing waste on production. Our consistently aim is to build high-performance, sophisticated Converting Machinery with inexpensive price as well as providing fast inspection machine service ensure our worldwide customers must be satisfied.

Live Broadcast of High-quality MIT Suppliers | 2022 Taipei Pack

This year, Taipei Pack Exhibition will continue to exhibit various types of packaging machinery, materials, and logistics from different Taiwanese Manufacturers. Of course, PRM Media Channel will continue to attend this year's exhibition with LIVE STREAM video interviewing different manufacturers and giving you insights about their machinery technologies and functionality. Event: Taipei Pack Exhibition Date & Time: June 23, 2022 , 15:00 (GMT+8) Location: Taipei Nangang Exhibition Center, Hall 1 (TaiNEX 1) If you are looking for a packaging machine or packaging relevant suppliers, We, PRM MEDIA CHANNEL, invite you to watch this LIVE STREAM! Stay tuned!

Eksim x PRM: Bridging Taiwan and Turkey in the Plastics Industry

Join us at PlastEurasia Istanbul 2024 as we interview Eksim, a prominent agent representing renowned Taiwanese brands like FKI, CLF, and LYM. Discover Eksim’s insights into the Turkish market and their strategies for building long-lasting, mutually beneficial relationships with Taiwanese manufacturers. Don’t miss this exclusive look into how Taiwan’s expertise supports Turkey’s growing demand for advanced plastic and rubber machinery!

Aluminum Foil Printing Techniques | WORLDLY

Have you ever wondered how essential it is for manufacturers and consumers to have the right packaging or sealing material on a decomposable product like medicine, snacks/drinks, or any other related product? By interviewing Klive from WORLDY, we have been explaining what kind of technical strengths Worldly has and they are capable of manufacturing and designing customization machines according to client's demand. Moreover, You will obtain the knowledge of the difference between plastic and aluminum foil to understand the applications of each materials.

Robot Arm, Take Out Robot, Injection Robot | ALFA ROBOT

Robot Arm, Take Out Robot, Injection Robot | ALFA ROBOT Originated from the parent company Alfa Auto Machinery Co., Ltd, Gamma is established based on the specific needs of customers. The chairman of ALFA, Mr. Shi Fuxing founded Dongguan Gmtek Technology Limited and Suzhou Gamma Automation Tech Co., Ltd in 2006 with the foundation of 2 million US dollars. The main services of Gamma are precision machining and professionally developed and manufactured high speed vertical machining center. Since the establishment, Gamma strives to fulfill the requirements of the customer and continue to provide the customers with the best service no matter if it’s precision, machining speed , the cost performance or the flatness.

Five Layer Blown Film Line | Multilayer Blown Film Machine | Blown Film Extruder - Kung Hsing

/ Kung Hsing Main Products / K.S. manufacture Agricultural Blown Film Machine, Inflation making machine, Flat Yarn making machine, Plastic strapping band making machine, Plastic Recycling Machine, as well as special design for all extrusion system machineries and whole plant projects. #KUNGHSINGPLASTICMACHINERY #BLOWNFILMLINE #MULTILAYERBLOWNFILM

Slitting Machine SLIT-HSI 1600 | WEBCONTROL

Inspection Rewinding Machine-Inspection Machine-I1-Inspect J300-Webcontrol Webcontrol Machinery Corp has been specializing in manufacture of Inspection Rewinding Machine since 1988. Webcontrol ceaselessly develop new machine to extend production line for meeting various needs of customers. In additions, we constantly improve our Inspection Rewinding Machine with new technology, and innovate to enhances its performance, efficiency and reducing waste on production. Our consistently aim is to build high-performance, sophisticated Converting Machinery with inexpensive price as well as providing fast Inspection Rewinding Machine service ensure our worldwide customers must be satisfied.

2024 TaipeiPlas International Plastics & Rubber Industry Show| Geording

In this video from the 2024 TaipeiPlas International Plastics & Rubber Industry Show, we present Geording’s machine designed to support green policies. With a self-cleaning screen changer, their equipment helps customers enhance efficiency and focus on green recycling development. Geording has maintained a long-term working relationship with Polaris, and we explore their experience with our services. Watch to learn more about Geording's commitment to sustainability in the plastics and rubber industry!

UHS Turret Slitter Rewinder - UHS-TR | WEBCONTROL

UHS Turret slitter rewinder The UHS-TR model is a proven fully automatic slitter rewinder, offered with many options to fulfill even the most demanding applications: - Cutting-edge slitting systems - Reliable auto cut and transfer - Advanced tension control - Combined with progressive differential winding technology - Precision and capacity at an affordable cost. - UHS-TR a must addition to any plant requiring quality Automatic knife positioning down to 25 mm slit width, double turret unwind, automated finished roll unloading systems are some of the available options to increase productivity, quality and decreasing operator influenced down time. Materials to be processed: Plastic film, paper and laminates Thickness range: -Rigid films: 10 – 200 micron -Soft films: 12 – 300 micron Machine Specification - SLIT UHS TURRET: -Web width:1300 / 1600 mm max -Unwind roll diameter: 1000 mm -Unwind roll weight: 1500 kg -Unwind roll cores: 3” and 6” I.D. -Finished roll diameter: 610 mm max -Finished roll cores: 3” and 6” I.D. -Slit width: 50 mm and up -Machine speed max: 600 m/min (depending on material type/quality) -Winding tension: 0.5 pli to 2.5 pli (11 - 45 kg) standard

Twin Head Blown Film Machine for Plastic Bag Manufacturers | POLYSTAR

Introducing POLYSTAR Twin Head Blown Film Machine with the motto of the company: "Extrusion Made Simple". The blown film extruder is specially designed for HDPE and LDPE bag producers. 【HIGHLIGTS OF Twin Head Blown Film Machine】 - Monolayer (1 Layer) - Two Die Heads, Single Screw - Film Width from 150~650mm - Extruder Dia: 45mm, 55mm, 75mm - Material: HDPE, LDPE - Output: 30~140 kg/hr - Works with virgin, recycled materials, Biomaterials, and CaCO3 - Possible end products: T-shirt bags, Bottom sealed flat bags, Shopping bags, Supermarket bags, Garbage bags 【MACHINE PORTFOLIO OF POLYSTAR】 1. BLOWN FILM MACHINES - One Layer Twin Head HDPE LDPE 650mm Machine - Multilayer Blown Film Machines - One Layer HDPE / LDPE 800mm (Mini type) Machine - AB - 2 Layer Co-Extrusion LDPE/LLDPE Machine - One Layer HDPE LDPE LLDPE 1500mm Machine 2. BAG MAKING MACHINES - Bottom Sealing Bag Making Machines - Folded Garbage Bags Machines - Perforated Bag on Roll Machines - Thick Bag Making Machines - Laundry Bags Machines 3. RECYCLING MACHINES - Plastic Recycling Machines - Plastic film recycling Machines - Two stage recycling Machines - Air cooled recycling Machines - Hopper feeding recycling Machines - Shredder integrated recycling Machines 【ABOUT POLYSTAR】 POLYSTAR is a pioneer manufacturer of Plastic Recycling Machines, Blown Film Extruders, and Plastic Bag Making Machines. The company has gained the trust of its customers with 32 years of experience in the industry, today POLYSTAR has been sold over 4,000 machines in 105 countries worldwide.

PET Recycling Innovations and Sustainability through Plastic Recycling | PARTICO

This time our guest is Partico Machinery Inc. Partico stands out with its customized thermoplastic recycling machines in Taiwan with over 25 years of experience. Dear Denny Chang and Lucy Huang, the sales representatives of the company, were really intimate to share their company's innovations and investments in R&D. By developing PET vacuum extrusion pelletizing system, Partico makes a distinction from other traditional manufacturers and creates its own market value. As a manufacturer of extrusion pelletizing machines, Partico is dedicated to calling for the importance of sustainability. The purpose of the company is not only to manufacture plastic recycling machines for the industry but also to assist in environmental protection with efficient machinery, as a part of the company's ESG contribution. The most important thing is that Partico is familiar with various materials that its machines can recycle. In addition, Partico is also capable to plan suitable conveyor systems for the customers according to their materials characteristics and applications, so they do not need to worry about the overall planning of equipment. In recent years, the main trend in the PET recycling industry is to apply pellets to make food contact materials. One of Partico's goals is to get FDA certificate, which refers to manufacturing recycling machines that recycle PET flakes for food packaging applications. We have more to share, then let's take a look at this intimate interview and learn more about Partico and its innovative contribution to the plastics recycling industry.

U Liner Bag Making Machine SHCG-75U | SING SIANG

SING SIANG MACHINERY CO., LTD

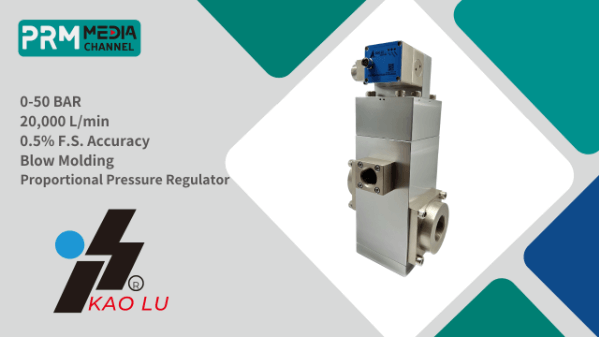

Ultra-Series QKL-HS1·HS2 Electronic Air Pressure Regulator | KaoLu

Product Description The low flow electronic pressure regulator (electric air pressure regulator) is suitable for industries that require precise pressure changes at any time and monitor pressure values. Moreover, the electronically controlled pressure regulator price of B3-1A is economical to this extent that the user can afford it with no hassle. Similar goes for electronic gas regulators; it's a digital air regulator that possesses the ability to resist massive quality air pressure. Over and above, the electronic pressure regulator (electronic proportional air regulator) Arduino is an open-source electronics platform that is especially designed to make electronic machinery more accessible in this digital era. The digital air pressure regulator facilitates the users with the digital reading of the present output pressure value. Another useful feature is an air flow regulator with digital pressure gauge that allows users to measure the quantity of the pressure allotted to the mechanical device for its operation. Available with 3 selections of input signal: 0-10VDc, 4-20mA, or RS485 Modbus. Monitor signals can be chosen from 1-5V, 0-10V, or 4-20mA. Our special design offers high pressure and high flow capability electronic air pressure regulators in unibody design. For applications that require a high pneumatic flow rate, we offer the option of an air pilot volume booster to amplify downstream flow. For applications that require an external pressure transducer, there is also an option to link our pressure regulators to external sensors for closed-loop control. All our electronic pneumatic regulator have CE, SGS, RoHS certification with ISO13485 quality system. Applications: Laser cutting, leak tester, tension control, PET bottle molding machine, multi-stage pressure control, etc. Applications for Electronic Pressure Regulators Spraying/ Painting Air Blowing Leak Testing Filling Pressure Artificial Heart Laser Cutting FAQ session – Proportional Electronic/Digital Pressure Regulators What are the differences between Proportional Pressure Regulator, Electronic Pressure Regulator, Electro Pneumatic Pressure Regulator Electronic, I/P Converter, Digital Pressure Regulator, and air flow regulator with digital pressure gauge? They are the same products with different names. Where is the digital pressure regulators used? Digital pressure regulator is usually used for laser cutting, plastic blow molding machines, tension control equipment, tire making machines, etc. Is the pressure regulator resistant to dirt? No, it is not resistant to dirt particles. Please use dry clean air and filter with < 5 μm. Any restriction on mounting orientation? Electronically controlled pressure regulator Arduino is especially designed to operate mechanics. There is no restriction on mounting orientation; however, please be aware to protect the regulator from environmental water drop, oil, and welding slag. Knowledge Base How Does a Proportional Pressure Regulator Work? A Proportional Pressure Regulator has many advantages over mechanical manual regulators. A manual regulator will maintain pressure downstream, most effectively with constant upstream flow rates. However, upstream flow and pressure will often fluctuate in most applications. Pumps and compressors deliver pulses, and the pressure will fluctuate with demand. When a mechanical pressure regulator lacks accuracy or can’t respond fast enough, the result is uneven pressure output. This simple device might be good enough when accuracy isn’t as crucial. However, a digital pressure regulator delivers better accuracy and stable output pressure by utilizing a control signal and the feedback signal to create closed-loop pressure control. Uses of Regulators Electronic pressure regulators (electric air regulators) maintain a constant output pressure within a pressurized system even if there are fluctuations in the incoming pressure to the regulator. Mechanical pressure regulators are typically only adjustable by hand, limiting their usability in a digitalized process environment. When using an electronic gas pressure regulator with a digital control system, the precise output pressure is controllable via slight adjustments to the control signal. An internal pressure transducer creates a closed loop control device and offers a feedback voltage of the current output pressure. By reading this feedback signal from an electronic regulator, control systems can make real-time adjustments, greatly improving consistent pressure regulation in the most demanding applications. The Working Process: Electronic pressure regulators (automatic air pressure regulator) are a big improvement over manual regulators; they are simple and very effective at allowing better control. An electronic air regulator uses a fill valve and a vent valve to maintain the outlet pressure at the desired set-point. A small inner pressure sensor monitors the output pressure and the digital controller adjusts the flow output of the internal valves to retain the required set-point (i.e. closed-loop control). That means that when you set the desired pressure, the regulator(pressure regulator digital) will maintain this pressure even with changing flow rates through the system. The internal pressure transducer gives immediate feedback to adjust the flow of either the fill or vent valve so the output pressure remains static. When the control signal increases, the internal proportional pressure control valve activates, increasing pressure into an internal pilot chamber. When this happens, more of the inlet pressure passes through the proportional fill valve and into the pilot chamber. The pressure in the pilot chamber grows and causes the upper surface of the diaphragm to operate. Because of this, the air supply valve linked to the diaphragm opens, and a portion of the supply pressure becomes output pressure. This output pressure goes back to the control circuit using the pressure sensor. The fill valve will continue to slightly adjust until the output pressure is equivalent to the desired set-point of the control signal. Please check our video on: GennDih Enterprise. Co. Ltd

JIT-SS |JIT T-Shirt Bag Making Line- |JANDI'S

Blown Film→Printing→Bag Making→Die-Cut Recovery, from resin to finished bags, ALL IN ONE PROCESS. HDPE / LDPE / Biodegradable / Compostable Material AVAILABLE

2023 IPF Interview | BPGMEA

It is our great honor to have the opportunity to interview Mr. Shamim Ahmed, the president of BPGMEA (Bangladesh Plastic Goods Manufacturers & Exporters Association). In the interview, Mr. Shamim shared much information about the plastic, printing and packaging industry, IPF Bangladesh is rapidly growing and gaining more exhibitors and visitors every year.

Flying Knife Cutting Bottom Sealing Bag Making Machine, MGA-BSF-1000W | MING JILEE

Flying Knife Cutting Bottom Sealing Bag Making Machine, MGA-BSF-1000W For Further information:https://www.mingjilee.com/en/product/Wire-Impulse-Bottom-Bag-Sealing-Machine-with-Flying-Knife-Cutter.html

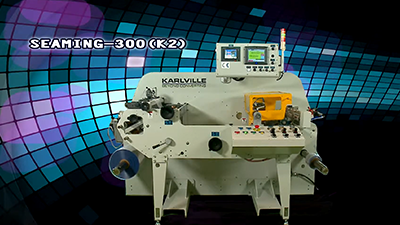

Seaming Machine | WEBCONTROL

Seaming Machine-300(K2)-Webcontrol Webcontrol Machinery Corp has been specializing in manufacture of Seaming Machine since 1988. Webcontrol ceaselessly develop new machine to extend production line for meeting various needs of customers. In additions, we constantly improve our Seaming Machine with new technology, and innovate to enhances its performance, efficiency and reducing waste on production. Our consistently aim is to build high-performance, sophisticated Converting Machinery with inexpensive price as well as providing fast Seaming Machine service ensure our worldwide customers must be satisfied.

2024 NPE Orlando Interview | WIPA

We are honored to have our first interview with Wipa, a high-quality plastic recycling machine manufacturer from Germany. In this interview, Wipa introduces their latest machine show at NPE, highlighting its features and benefits for the plastic recycling industry. Join us to learn more about this innovative technology and how Wipa continues to lead performance.

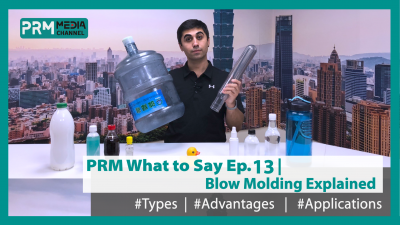

Plastic Blow Molding Process Explained | PRM What to Say EP 13

In blow molding, hollow plastic components are formed through a producing process categorized into three main methods: injection, extrusion, and injection stretch blow molding. In this episode of PRM What to Say, the plastic blow molding process is explained. Besides, we also mentioned some common benefits of the blow molding production method. For more info and machine manufacturer info, you can refer PRM-TAIWAN Blow Molding Machine category at Blow Molding Machine Category Since blow molding allows freedom for design and engineering, the range of applications that you can manufacture by blow molding is really wide. The automotive industry, Appliance components, Medical supplies and parts, Children’s toys, Packaging, Sporting Goods, and Industrial bulk containers are where we see blow molded products often. The blow molding process is very suitable for automation. Especially using the robot technology for take out units and packaging offers the benefit of faster production. Besides that, you can also reduce labor costs by using automation.

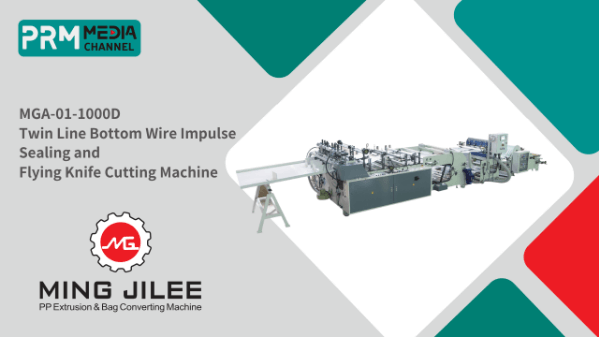

Twin Line Bottom Wire Impulse Sealing and Flying Knife Cutting Machine MGA-01-1000D | MING JILEE

Twin lines Bottom Bag impulse sealing and flying knife cutting machine, MGA-01-1000D

Bag Making Automation Solutions at K 2022 | PLAS ALLIANCE

It's such a great honor to interview Eugene Chiu, the Sales Manager from PLAS ALLIANCE LTD. In the interview, he mentioned influences by the pandemic. In the end, he also talked about the trending topics in recent years, for instance, Circular Economy. PLAS ALLIANCE LTD. also has excellent customization ability. They provide customized machinery, especially when their customers are searching for Biodegradable Materials applications.

CHINAPLAS 2025 | Innovation and Collaboration for Sustainability

Experience the future of plastics at #CHINAPLAS2025! Shenzhen World Exhibition & Convention Center (Bao'an), Shenzhen, PR China 15-18 April, 2025 Let's embark together on this journey of innovation, collaboration, and sustainability! See you there #PlasticsInnovation #CHINAPLAS

High Speed Zipper Bag Making Machine With In-Line Zipper Lamination | MGA-06Z-800D

High Speed Zipper Strip Hot Lamination Side Sealing Machine, MGA-06Z-800D Zipper bag side sealing machine is latest design to produce zipper bag / Ziploc bag / IKEA zipper bag/ grape bag/ slider zipper bag. The zipper bag side sealing machine is equipped 3 sets of servo motors to control the best tension and high speed production. The zipper bag side sealing machine is equipped in-line zipper strip sealing station. MACHINE PERFORMANCE (1) Feed material : LDPE, HDPE, PP, EVA (2) Single layer film thickness a. Side sealing bag : 0.02 - 0.08 mm b. zipper bag : 0.04 - 0.08 mm (3) Effective bag width (feeding length) : 85 - 600 mm (4) Effective bag length (sealing width) : 150 - 650 mm (5) Output : 40 - 200 pcs /min (depend on size and thickness) FEATURES (1) The PLC controller is made in Taiwan and very stable. (2) The size control of Zipper Bag Side Sealing Machine is by servo motor. Made in Japan (3) Zipper Bag Side Sealing Machine is equipped mark sensor for printed material (4) For getting the best quality of zipper bag product, unwinding station is mount the auto tension control (5) The individual zipper strip unwinder with motor control to get the high quality of zipper sealing quality. (6) Ultrasonic welding is design by motor driven for highest speed production (7) The ultrasonic welding station to crack the zipper on the edge of the bag for easy side sealing cutting. (8) the best design of zipper bag side sealing machine, made in Taiwan

Sensing & Polymer Test Equipment at K 2022 | Dynisco

We are glad to have an interview with Bill Desrosiers, Vice President of Dynisco, since our last interview at K 2019. The industry has been changed a lot due to COVID said by Mr. Desrosiers. Moreover, we had a discussion of how Dynisco implemented trending topics at K 2022, such as Circular Economy, Digitalization and Environment Protection, and applied these concepts in Dynisco products.

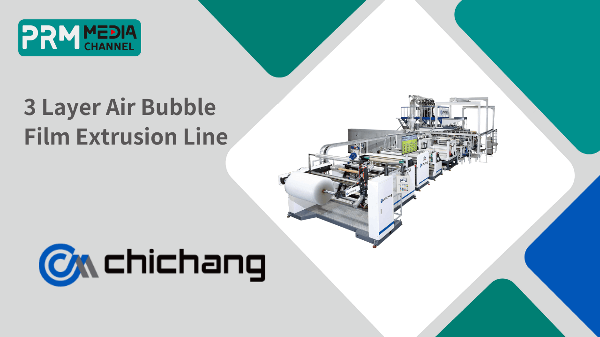

3 Layer Air Bubble Film Extrusion Line | CHI CHANG-

MACHINERY IN THE VIDEO: 3 Layer Air Bubble Film Extrusion Line from CHI CHANG MACHINERY APPLICATIONS: The main uses of the Air Bubble Sheet are: Packaging of electronic material with anti-static additive. Agricultural sector (green house) with anti-UV additive. Covering of swimming pool with anti-UV additive. Typical packaging with anti-shock, anti-abrasion and anti-crushing functions. Laminated with paper, PE woven and aluminum foil for making envelope.

Bio Resin Bag Making Line - JIT Series | JANDI’S

JANDI'S INDUSTRIAL CO., LTD. is committed to developing blown film machines combined with bag making, printing, and recycling machines. Until 2018, they obtained more than 30 patents of plastic machinery in China and Taiwan. With the concept of plastic reduction raising, JANDI'S proposes an idea about green innovation. The company develops JIT series integrated plastic bag making machines that are 100% suitable with biodegradable and compost materials such as PBAT and PLA. Moreover, JANDI'S added the automatic packaging part to JIT series.

Extrusion Blow Moulding Machine |FONG KEE

Extrusion Blow Moulding Machine - High Speed Blow Moulding Machine-hbb-ssg-Fong Kee Specializes in Extrusion Blow Moulding Machine, Fong Kee International Machinery Co., Ltd. (FKI) is the largest and finest Extrusion Blow Moulding Machine manufacturer in Taiwan Plastic Extrusion Industry. Established in 1953 by founder C.C Wei and spread its business to over 100 countries . FKI manufactures variety of Extrusion Blow Moulding Machine and etc. If you are looking for good Plastic Extrusion Machine Supplier, please feel free to contact us.

Plastic and Rubber Industry B2B Platform | PRM-TAIWAN

Are you looking for plastics and rubber suppliers for machinery, molds, raw materials, auxiliaries, and so on? Here is PRM-TAIWAN B2B Platform only one click away. Visit our website now and search for your Taiwanese suppliers. #PRMTAIWAN

Industry 4.0 Smart Factory for Injection Molding - sFactory 4.0 | SHINI

【VIDEO FOCUS】: SHINI Industry 4.0 Smart Factory for Injection Molding which is called "sFactory 4.0" 【ABOUT SHINI】 Derived from Taipei, Taiwan, Shini group has gone through an extraordinary journey for more than 40 years. To date, Shini group has established six production bases and one corporate technology center globally. Specialized in manufacturing plastic auxiliary equipment, Shini products consist of eight series, including drying & dehumidifying, feeding & conveying, dosing & mixing, heating & cooling, granulating & recycling, automation solution, systematic solution, and hot runner system. Adhered to the management principle “focusing on a particular business, pursuing to be the world leader”, Shini people have created new situations one after another. Till now, Shini group has ranked among the world-class manufacturers of plastic auxiliary equipment and taken the lead of Asia's plastic auxiliary equipment industry.

Die Cutting Machine Manufacturer | Yicheen

Yicheen High Precision Die Cutting Machine offers a variety of options, such as CCD Auto Positioning, Auto movable Stacking, etc., click the link to see more Die Cutting Machine info: ???? https://bit.ly/3qbjbtf

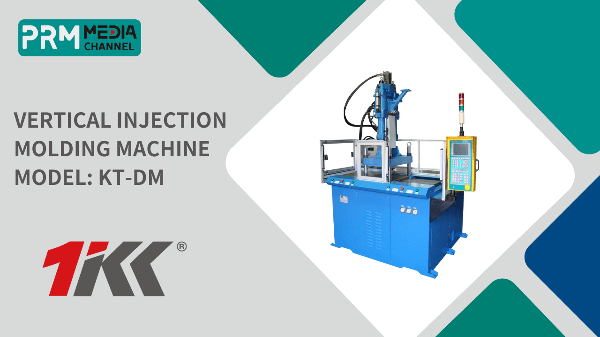

Vertical Injection Molding Machine - KT 300 | TAIWAN KINKI

FEATURES: 1.Vertical mold clamping and injection, small footprint, and high degree of precision. Our Vertical Injection Moulding Machine is ideal for the injection of medium and small products with inclusions. 2. Direct-pressure mold clamp allows even injection force, and the relatively low pressure means maximum precision and an incredibly smooth cycle of operation. 3.KT-300 Vertical Plastic Injection Molding Machine offers a wide range of programmable functions including automatic inclusion, extraction, and fully-automatic production. 4. Dual-cylinder injection system offers high injecting pressure for fast operation, making this injection machine your best choice for the production of thin items. 5. Choose a platen or a rotary plate in accordance with the type of products to be injected, in order to achieve the best possible in feed and injection effects. 6. There are also many other control systems that facilitate flexible production and keep costs low while maximizing precision.

Two Platen Injection Molding Machine 600TPIIR | CLF

Two Platen Injection Molding Machine 600TPIIR 3D animation from CLF. CLF is specializing in manufacturing plastic injection molding machines with super-large, high precision, and high performance. 【HIGHLIGHTS OF THE MACHINE】 Clamping Force 1800~4000 TONS Unique two-platen design for clamping mechanism exhibits exceptionally high-speed clamping feature. Clamping force, mold opening stroke, and distance between tie bars are easy to customize. Quick and accurate mold adjustment makes the machine suitable for small lot flexible production. Uniform force distribution on mold ensures the high accuracy of the product. Uniform tension force on tie bars for the dramatic increase of service life. Simplified construction with no wearing problem on toggle clamp. Rigid machine structure, minimum deformation, and consistent product accuracy.

Recycling Solutions for Packaging Industry | POLYSTAR Interview

At the recent TAIPEI PACK 2020, the famous packaging machinery exhibition of Taiwan, we have interviewed Ms. June Pei, from POLYSTAR. POLYSTAR is one of the most famous and leading recycling and blown film machines manufacturer from Taiwan, and has sold machinery in many countries around the globe. Ms. Pei shared her opinions and observations about the packaging industry, their recycling solutions related to the packaging industry, and also introduced the machinery they are showcasing at the exhibition. Moreover, she also mentioned the implementations to ease the effects of the pandemic on the business and the solutions they provide to their current and potential customers. Let's watch the interview video together and learn more. Thank you for your opinions and questions that you can leave as a comment. Remember to subscribe to our social media channels for the forthcoming interview videos and similar videos!~

2024 Expo Plasticos Guadalajara | Organizer Executive Jeorge

Dive into our exclusive interview from the Mexico Plastics and Rubber Industry Expo 2024, where we explore the event’s commitment to sustainability and circular economy practices. This year’s expo features 100% recyclable carpeting, aligning with ESG goals and showcasing the industry’s push toward a greener future. The event has attracted numerous professional buyers, with a bustling atmosphere fueled by nearby factories and industries in Guadalajara. Join us as we uncover the organizers’ objectives and hopes for this year’s exhibition. After watching, visit our PRM platform for a comprehensive post-show report to see if these goals were met. Don’t miss out on the highlights and insights from one of the industry’s most vibrant events!

CHINAPLAS 2021 | PRM What to Say EP1

PRM Media Channel is here with a brand new program: PRM What to Say. More Info: https://bit.ly/2RngTZM Due to the rapid transformation in many industries because of pandemic, including plastics and rubber industry, we all realized the power of social media and video marketing. Through PRM What to Say program hosted by PRM Media Channel, we aimed to bring current issues of plastics and rubber industry on the table, and discuss these topics with experts and listen the possible solutions. Let's take a look at our first episode about CHINAPLAS 2021 and let us know your opinions and questions in the comments section. Thank you for your support!~

FSL-TR series Turret Rewind Slitting Machine | HCI

HCI’s newly launched FSL-TR1300 turret rewind slitting machine is designed for automatic slitting and rewinding operations, with automatic splicing and roll changing, stand-by paper core auto positioning, finished roll pusher and unloading device to increase productivity and reduce the operation down time. The HMI operating system equipped with a color touch screen provides easy-to-learn operations and memory of operating parameters, which makes the product quality stable.

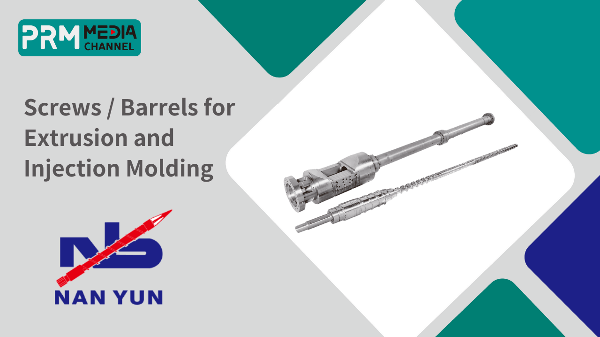

Screws / Barrels for Extrusion and Injection Molding | NAN YUN

As leading company of Screws and barrels in Taiwan, Nan Yun is able to provide the highest quality screw and barrel for Extruder Machine. We are continually researching new screw and barrel materials that would best fit the needs for pellet extruder or plastic pelletizing machine, which results in better mixing, and critical melt quality. Nan Yun's engineers work with our customers to provide the best possible extruder screw design for extruder machine such as PVC pelletizing machine, PE pelletizing equipment, Plastic pellet extruder.

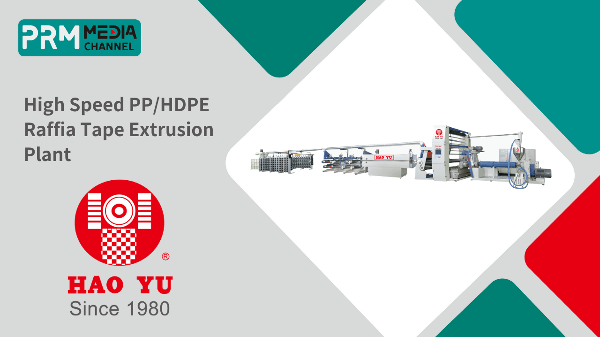

High Speed PP/HDPE Raffia Tape Extrusion Plant | Raffia Tape Extrusion Line | HAO YU

【New generation high speed PP/HDPE raffia tape extrusion plant - GV series (Green Veloz)】 / Raffia Tape Extrusion Line/Plant Features - (HY7/SP-80GV) / ⚡️Suitable for making 100% recycle PP/HDPE materials ⚡️Finish products complies with the requirement of GRS(Global Recycled Standard). ⚡️Meet the requirements of companies interested in selling their products to ESG approved companies. ⚡️Rapid color changing.