PET Recycling Innovations and Sustainability through Plastic Recycling | PARTICO

This time our guest is Partico Machinery Inc. Partico stands out with its customized thermoplastic recycling machines in Taiwan with over 25 years of experience. Dear Denny Chang and Lucy Huang, the sales representatives of the company, were really intimate to share their company's innovations and investments in R&D. By developing PET vacuum extrusion pelletizing system, Partico makes a distinction from other traditional manufacturers and creates its own market value. As a manufacturer of extrusion pelletizing machines, Partico is dedicated to calling for the importance of sustainability. The purpose of the company is not only to manufacture plastic recycling machines for the industry but also to assist in environmental protection with efficient machinery, as a part of the company's ESG contribution. The most important thing is that Partico is familiar with various materials that its machines can recycle. In addition, Partico is also capable to plan suitable conveyor systems for the customers according to their materials characteristics and applications, so they do not need to worry about the overall planning of equipment. In recent years, the main trend in the PET recycling industry is to apply pellets to make food contact materials. One of Partico's goals is to get FDA certificate, which refers to manufacturing recycling machines that recycle PET flakes for food packaging applications. We have more to share, then let's take a look at this intimate interview and learn more about Partico and its innovative contribution to the plastics recycling industry.

2024 TaipeiPlas International Plastics & Rubber Industry Show| Geording

In this video from the 2024 TaipeiPlas International Plastics & Rubber Industry Show, we present Geording’s machine designed to support green policies. With a self-cleaning screen changer, their equipment helps customers enhance efficiency and focus on green recycling development. Geording has maintained a long-term working relationship with Polaris, and we explore their experience with our services. Watch to learn more about Geording's commitment to sustainability in the plastics and rubber industry!

Vertical Injection Molding Machine - KT 300 | TAIWAN KINKI

FEATURES: 1.Vertical mold clamping and injection, small footprint, and high degree of precision. Our Vertical Injection Moulding Machine is ideal for the injection of medium and small products with inclusions. 2. Direct-pressure mold clamp allows even injection force, and the relatively low pressure means maximum precision and an incredibly smooth cycle of operation. 3.KT-300 Vertical Plastic Injection Molding Machine offers a wide range of programmable functions including automatic inclusion, extraction, and fully-automatic production. 4. Dual-cylinder injection system offers high injecting pressure for fast operation, making this injection machine your best choice for the production of thin items. 5. Choose a platen or a rotary plate in accordance with the type of products to be injected, in order to achieve the best possible in feed and injection effects. 6. There are also many other control systems that facilitate flexible production and keep costs low while maximizing precision.

T-Shirt Bag Making Line with Carton Packaging Line|JIT-SS 4 sets full auto. in-line|JANDI'S

#PlasticReuse #MachineManufacturer #PlasticRecyclingMachine 00:00 Opening 00:08 Blown Film 00:28 Machine current speed 00:37 Cutting, Sealing & Punching 00:54 Sending finished bag to Carton Packaging Section 01:07 Take-up Tower & Printing 02:27 Carton Packaging Proccess 05:04 Ending --- Website : www.jandis.com.tw & www.inflationmachine.com Facebook : www.facebook.com/JANDIS.JIT Email : [email protected]

Fully Automatic Coreless Bottom Sealed Bags On Roll Making Machine | CHAO WEI

【Machine Spec & Features】 Bottom Sealed Bags On Roll Making Machine (Coreless) Film width: 600 mm / Thickness: 15 micron E.P.C Control & Rollers Device (E+L, German made) Length: 750 mm x Speed: 135 Pcs/Min Production Line Speed: 100M/Min Servo Driven Shuttle Type Sealing & Perforating Unit Two Sets Triangle Folders For Making Finished Roll With Small Width Machine Maintains High Speed Production By 4 Sets Rewinding Shafts While Producing Small Quantity Of Bags Per Roll 【Company Introduction】 Chao Wei Plastic Machinery is an advanced manufacturer of plastic bag making machine with more than 35 years of experience with ISO 9001 & CE certificates in Taiwan. One of the reasons for the excellence of Chao Wei’s machines is our dedication to research and development.

Sustainable Innovation of Blown Film Machine | KUNG HSING-

The latest innovation of Three Layer Blown Film Machine is featured with 3 in 1 Gap Winder that combines Surface Type, Contact Drive Type and Gap Winding. We are pleased to invite Kung Hsing Machinery to share the insight of the Blow Film Industry with us, which includes application, ESG and the effect of geopolitic to the economy.

Company Introduction | ALFA

Alfa Industrial soul thought - professional quality, put product quality in the first place. Whether it is the procurement of parts in the early stage or the final machine inspection, Alfa Industrial strictly monitors every link, every process and every detail to ensure the stability and performance of each machine. Email: [email protected]

Bag on Roll Making Machine-Draw tape Garbage Bag|Plas Alliance Ltd.

Are you looking for plastics and rubber suppliers for machinery, molds, raw materials, auxiliaries, and so on? Here is PRM-TAIWAN B2B Platform only one click away. Visit our website now and search for your Taiwanese suppliers. Learn More : • Bag on Roll Making Machine|Draw tape G... ------------------------------------ Draw tape garbage bags are advanced type of garbage bags which has strong tensile strength and puncture resistance, and controlled elongation for volume. The draw tape can be pulled and knotted for secure closure. Bag on roll are good and compact for transportation and end use for household consumers. - Bag making application - Draw tape garbage bag on roll - Folded draw tape garbage bag

CHINAPLAS On-site Tour Hall No.7 | PRM-TAIWAN

What! You don't know which manufacturers are participating CHINAPLAS? Hurry up and check out the CHINAPLAS on-site tour brought to you by PRM. Let Alice show everyone the charm of the CHINAPLAS. Welcome to PRM's booth if you are interested in the first-hand marketing and trade news of the Plastic and Rubber industry. ->PRM booth number: 7G01

Circular Loom Machine - 6 Shuttle Circular Looms | HAO YU

Introducing 6 Shuttle Circular Looms Machine from HAO YU. With HAO YU HY7-m6SCL six shuttles circular loom is designed with 6 shuttles to perform tubular weaving at high speed up to 180 RPM which is the highest technology in this woven bag equipment field in Asia. It reaches outputs up to 140 meters per hour. In case warp and weft breaks (finished), the machine stops automatically, An auto compensation system is also equipped to prevent the machine from empty weaving, it is an advanced circular loom specially designed to meet the stringent productivity requirements of today. The circular looms equipped with European inverter and high quality components. HAO YU is applying patent in Taiwan, China, India, and other countries. 【Machine Features】 Low spare part consumption & easy maintenance Energy saving nearly 50% over conventional models Large weft yarn insertion capacity up to 1080 PPM(max) Flat yarn applicable weaving denier from 500-1200(standard) Large weft yarn carriage capacity up to 115mm(max) Equipped with European inverter for main motor Lubrication-free for shuttle & cam 【Optional Accessories】 Gusseting device Both sides heat slitting device and additional fabric winder Center unfold device with heat slitting device and extra large unwinder for cement bag industry 【ABOUT HAO YU】 Hao Yu has been dedicated to manufacturing PP/PE/PET woven bag machinery and whole-plant equipment since its establishment in 1980. Enhancing present machinery and developing new models are Hao Yu’s objectives in order to improve the efficiency, product quality, and profitability for their customers.

TaipeiPLAS 2022 Live | PRM

The self-media era is coming! The plastics & rubber industry not only allows specific people or professionals to learn about this area. Throughout PRM's interview videos, we convey general information from plastics & rubber industry, environmental issues and social enterprise responsibility topics. ⏰ 10/1(Sat.) 15:00 (GMT+8) 【PRM exhibition insight interview】 We'll introduce the innovative machinery and techniques by interviewing exhibitors at TaipeiPlas 2022. To those who cannot attend the exhibition and overseas buyers, you can watch our on-site interviewing video to obtain the latest information.

Interleaved Draw Tape Bag On Roll Converting System ft. Labeling Device | LUNGMENG

【Feature】 High-speed servo-driven system Special sealing system, keeping the production speed steady regardless of the film thickness and length Convenient sealing knife system, with easy changeovers of sealing knives, making production more flexible Unique perforating knife system for various film materials Intellectual rotary interleaved winder with the 2-in-1 system applicable to bags on roll and interleaved bags User friendly touch screen control system Reliable & multi-functional system, capable of producing star sealed bags, wave type bags, table covers and many more through modular system changes 【Company Introduction】 Lung Meng Machinery also known as Dragon Plastic Machinery was established in 1976 as a professional plastics converting machinery manufacturer. In 1983 Dragon Plastic developed “All In Line System”, which allows blown film extruders, printers and bag machines to work together in-line. Lung Meng Machinery's wide range of innovative machines are the very solution to exceed customer's expectation at a satisfactory price. After 46 years of continuous research and development, Dragon Plastic has become the only company that can integrate all three kinds of machines together in an in-line process.

Plastic Recycling Machine, Repro-Flex | POLYSTAR

【Machine Features】 The one-step plastic pelletizing machine, Repro-Flex, combine cutting, extrusion, and pelletizing into one compact and efficient pelletizer line. The cutter-compactor of the plastic pelletizing machine prepares the plastic waste (PE plastic film and PP plastic film waste) into an ideal condition for the extrusion process and feeds the plastic waste directly into the extruder. This integrated system does not require a separate crusher, and therefore, eliminates the problem of inconsistent feeding, reduces space and labor costs, and has lower energy consumption. Simple in Design. Flexible in Operation. POLYSTAR is able to customize its machines regarding customers’ needs. How this pelletizing system works: 1. Feeding a. By belt conveyor Feeding of scraps is easy and automatically controlled depending on the amount of material input. b. By Nip roller Film-on-rolls can be fed at the same time. 2. Cutting and compacting The cutter compactor integrated cuts, dries, and compacts the material which enables a fast and stable feeding from the compactor directly into the extruder. 3. Degassing system The two-zone degassing can process plastic film with larger printed areas. 4. Filtration Screen change with a dual channel system for non-stop operation that also prevents plastic material from leaking. 5. Pelletization Water-ring pelletizing system, also known as hot die face pelletizing, the plastic comes from the recycling extruder and is directly cut by the rotating knives attached to the surface of the die head. 6. Final Product Round-shaped recycled pellets are produced and cooled inside the water ring immediately. 【Company Intro】 Headquartered in Taiwan, POLYSTAR has focused on the user-friendliness of its machines through continuous re-engineering, making recycling extremely “Simple” for its users – Easy operation and maintenance is what makes POLYSTAR the No.1 selling recycling machine today. Over the past 32 years, more than thousands of POLYSTAR recycling machines have helped worldwide plastic producers to reprocess their post-industrial (in-house) waste back into high-quality pellets in a simple and easy way.

Core Objects for Plastic & Rubber Machines | NAN YUN

Do you know SCREWS and BARRELS? Those are dispensable parts to injection molding machines, extruders and relevant machines in the plastic and rubber industry. Nan Yun Industrial Co., LTD., an expert who specializes in designing and manufacturing a full range of screws and barrels. With more than 30 years of experience, Nan Yun’s team provides customization services to meet customer’s special applications. By interviewing Mr. Kuo-Feng Huang, Assistant Manager of ST Dept., we also discussed an important engineering technology concept “Reverse Engineering” and how Nan Yun applied it into their business. Moreover, after-sales service is one of Nan Yun’s values. By Gathering feedback and reviewing consultation forms in past years, they could provide accurate solutions to their customers. 【Video Outline】 00:00 - Introduction 00:45 - The role of Nan Yun 01:22 - The specialty of Nan Yun 03:03 - Service during the pandemic 03:37 - Solutions to customer’s problems 04:25 - Future plans and messages to customers 05:23 - Closing

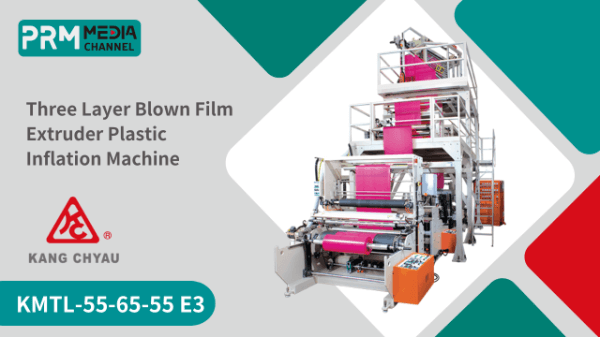

Three Layer Blown Film Extruder Plastic Inflation Machine | KANG CHYAU

Introducing three-layer blown film extruder machine, in another name called three-layer plastic film inflation machine. From one of the pioneering blown film extruder manufacturers in Taiwan, KANG CHYAU. For more information and/or inquiry, please directly contact the manufacturer at the contact button. For any assistance, PRM will be more than happy to assist, please use CONTACT PRM button to leave a comment below. Then we will reply and contact you asap. Machinery in the video: THREE LAYER BLOWN FILM EXTRUDER PLASTIC INFLATION MACHINE | Model No: KMTL-55-65-55 E3 Film Width: 500-1800 mm Screw Diameter: Ø 40-45-40/45-55-45/55-56-55 mm Suitable Materials: HDPE/LDPE/LLDPE/mLDPE

Find Your Plastic & Rubber Supplier | PRM-TAIWAN

Welcome to PRM-TAIWAN Plastic & Rubber B2B Website introduction video. In this video you will watch how to find Taiwanese Plastic and Rubber Machinery suppliers through PRM-Taiwan. It's so simple! Just go to www.prm-taiwan.com select the machinery or materials, and send your inquiry. Leave the rest part to us.

Eksim x PRM: Bridging Taiwan and Turkey in the Plastics Industry

Join us at PlastEurasia Istanbul 2024 as we interview Eksim, a prominent agent representing renowned Taiwanese brands like FKI, CLF, and LYM. Discover Eksim’s insights into the Turkish market and their strategies for building long-lasting, mutually beneficial relationships with Taiwanese manufacturers. Don’t miss this exclusive look into how Taiwan’s expertise supports Turkey’s growing demand for advanced plastic and rubber machinery!

Slitting Machine (HS-Compact) | WEBCONTROL

The SLIT-HSC series slitter is new compact type to save the working space. From the unwind side, the web is guided middle to the main machine, easy access to the slitting section and eliminates dust collection/hazarded steps. The slitter comes standard with razor cutters and groove roller configuration. A shear cutter system is offered as option for paper and other pressure sensitive materials. The machine uses three AC Vector Drives and has automatic tension on unwind and rewind controlled through easy-to-use PLC & MNI touch screen. Friction rings are used on rewind shafts to ensure the production of quality slit rolls when the film thickness varies.

Slitting Machine SLIT-HSI 1600 | WEBCONTROL

Inspection Rewinding Machine-Inspection Machine-I1-Inspect J300-Webcontrol Webcontrol Machinery Corp has been specializing in manufacture of Inspection Rewinding Machine since 1988. Webcontrol ceaselessly develop new machine to extend production line for meeting various needs of customers. In additions, we constantly improve our Inspection Rewinding Machine with new technology, and innovate to enhances its performance, efficiency and reducing waste on production. Our consistently aim is to build high-performance, sophisticated Converting Machinery with inexpensive price as well as providing fast Inspection Rewinding Machine service ensure our worldwide customers must be satisfied.

Best Choice Of PET Extrusion Pelletizing Machine Line From Partico Machinery, Inc | PARTICO

Model no:HF-FTO-135 3 in 1- Flow Channel Pelletizing System Double Filters system: no.1 Double pistons(Back flush) no.2 CPF Spec:The dia of screw 135mm Output:500-600kg/hr Application:PET yarn, flakes, fiber, filament

Hydraulic Die Cutting Machine (HDR 0505) | Yicheen

Yicheen specializes in manufacturing Rewinding Hydraulic Die Cutting, which high speed sliding table feeding, motion is fast and safe.

Business Tips of Choosing Plastic Recycling Machine | PRM What To Say EP17

Do you understand different kind of plastic recycling machines? Each type of plastic could be processed by certain type of machine. If you are still confused in choosing machines for your business, you must watch this video.

Bangladesh Culture and Tips on Operating Market | PRM What To Say EP18

Bangladesh has a rich, diverse culture. Its deeply rooted heritage is thoroughly reflected in its architecture, dance, literature, music, painting and clothing. For this episode, we’re going to talk about Bangladesh culture and tips on the operating market. Let PRM Cicilia share her insight and observation about Bangladesh Market!

Plastic Recycling & Pelletizing Machine | GEORDING

【Product Line】 Plastic recycling machine Compounding machine Dyeing & Pelletizing Automatic batch weighing and mixing system Washing line Rubbing drying machine Powerful crusher Shredder Plastic flat board extruder Refuse derived fuel (RDF) 【Company Intro】 GEORDING MACHINERY CO., LTD. has dedicated to innovating their machines with superior features which can process various plastic materials, such as PA, PET, ABS, TPU, Calcium Carbonate and even PE foam. By keeping developing and improving their technology, GEORDING has become one of the leaders of the extruder supplier as well.

Shrink Sleeve Conversion Seaming Machine - K5 Plus | WEBCONTROL

Machine Specification - WEBCONTROL Seaming Machine K5 Plus: -Machine Speed: 500 m/min -Width: 350 mm -Material Width: 720 mm -Unwind Diameter: 600 mm (Option 800 mm) -Rewind Diameter: 600 mm -Minimum Lay Flat Width: 40 mm with 18 mm option -Core Diameter: 3" (76 mm) -Lay Flat Tolerence: 0.25 mm The K5 PLUS combines all the advantages of the new PLUS technology with non-stop operation. The new PLUS series is the most advanced seamer in the industry. WEBCONTROL has once again innovated by launching the third generation of seamers which eliminates the forming tool. This new patented design makes the K5 PLUS the most operator friendly machine available, facilitating operator training with the most automated machine on the market. The K5 PLUS has 3 tension zones, which allows for a dedicated tension zone in the forming section for better layflat control. The unwind tension zone is now free to add innovations like laser integration for t-perforation or pin hole perforation while the film is flat. The K5 PLUS offers a long list of advantages that solve the issues that come with the previous generation of machines that use forming tools. This new machine promises to revolutionize the way shrink sleeves are converted. Make sure you see it before making any decisions.

Co-rotating Twin Screw Extrusion | CYKF

Did you know that? Because of the low cost and material versatility, strand pelletizing is the most commonly used pelletizing system. Description: 1. Heating & Cooling System: The material can keep the best temperature in the manufacturing by alternatively using hot water and cold water. 2. Stable Feeding System: The designed screw can avoid material stuck and causing uneven feeding. The feeding quantity can be adusted according to needs. 3. Side Feeder: Used for adding additives including powder, liquid, or pellet type, the side feeder can arrange an automatic system that supplements additives by itself. 4. Vacuum Unit: Purify the pellet by getting rid of exhaust gas or steam from materials. 5. Water Cooling Unit: The water tank cooled the strand plastic, and the organized water tank remains the proper temperature to make the plastic straight and unbroken. 6. Dryer: The dryer removes water from the strand plastic surface with strong wind, and the removed water will return to the water tank eventually. 7. Pelletizer: The pelletizer cut strand plastic into pellets, and the rotate speed can adjust freely, customers can also change other models for bigger productivity. More product information please visit our website: https://www.cykf.com.tw/tw/product/Strand-Pelletizing-System.html

Flexographic Printing Machine | LEEWIN

【Product Lines】 In-line Flexo Printing Machine FSP Off-line Flexo Printing Machine Chamber Dr. Blade Flexographic Printing Machine LL Off-line Flexo Printing Machine Heavy Duty Flexo Printing Machine Logo Flexo Printing Machine Flexographic Printing Machine for Biodegradable Plastic Bag Flexo Printing Machine Opional Equipment 【Company Intro】 LEEWIN brand Flexographic Printing Machines are suitable for reel-to-reel printings of fiber glass cloth, PP/PE woven bags, cellophane, aluminum foil, roller paper, packing paper, tubular films, and PP / HDPE / LDPE / LLDPE polyester bags.

Exclusive Interview: Jawhari Kamil on the 20th Saudi PPPP and Vision 2030

Join host Jason as he sits down with Jawhari Kamil, chief organizer of the 20th Riyadh Expo, for an insider’s look at this landmark event. In just a few minutes you’ll learn: What makes the 20th Saudi PPPP and how it reflects Saudi Arabia’s rapid industrial momentum Kingdom Vision 2030 in action—why national transformation goals are shaping every corner of the show Sustainability in focus: from low-carbon solutions to green partnerships that matter A surprise reveal: Jawhari hints at a major collaboration with a world-famous exhibition coming in 2026—watch to the end to find out which one! Whether you work in plastics, packaging, or any sector eyeing the Middle East, this interview delivers fresh insights you won’t want to miss.

3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine | GEORDING

3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine - GEOR-DING MACHINERY CO., LTD.. We specialize in manufacturing of 3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine. The main businesses include: 3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine and planning of entire plant’s equipment. While the demand for output and quality in 3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine worldwide is increasing day by day, our determination for upholding the motto, "Quality is number one. Output comes second. Customer satisfaction. Perfect service”, will never shift. Under your support and encouragement, we will continue to provide quality 3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine products and services to higher standards.

KAIMEI | PE Extruding Blow Molding Machine for Product Maximum to 1,500L - PBI-1305X-

Kai Mei Plastic Machinery Co., Ltd. established in 1977, is a highly reputed manufacturer of blow molding machines. Different types of machines are designed to produce containers of various raw materials such as PE, PVC, PP, PETG, PU, etc. Kai Mei can produce 5-ml containers of PBA Series Machines to 1,500-liter containers of PBI-X Series Machines. These are fully recognized by customers around the world.

3 Layer Air Bubble Film Extrusion Line | CHI CHANG MACHINERY

【Applications】 The main uses of the Air Bubble Sheet are: Packaging of electronic material with anti-static additive. Agricultural sector (green house) with anti-UV additive. Covering of swimming pool with anti-UV additive. Typical packaging with anti-shock, anti-abrasion and anti-crushing functions. Laminated with paper, PE woven and aluminum foil for making envelope. 【Compnay Introduction】 Since our founding in 1972 CHI CHANG MACHINERY ENTERPRISE CO., LTD has been on a never-ending quest for breakthroughs and innovations in technology. CCM ensures that wherever our customers are in the world, all of our extrusion equipment and services reach outstanding levels of performance. Adhering to our motto of Integrity, Innovative technology and Sustainable services, CCM is dedicated to the design and fabrication of plastic extrusion machinery.

Label Converting and Finishing System | YICHEEN

Machinery in the Video: Label Converting and Finishing System from YICHEEN Features: * Running operated by full rotary die cut method or intermittent die cut method. * Die is easy in change, save a lot of time in die mold adjustment. * Micro adjustable for the depth of die, able to dotted line cut/full cut/kiss cut procession. * Servo driver and HMI control system, easy in operation, to upgrade the speed and precision control. * Sensor detector and alert for broken material to reduce material lost. * Optional module for satisfying customized demands. * Optional Mechanism: EPC, Laminating, Die Cutting (Front & Back Die Cut), Liner Razor, Varnishing, Slitting/Cutting Sheet * Application: IML(in mold label), Self-adhesive Label, Sticker, Foam, IPO, Single/Double sided adhesive, Post-press finishing material, and so on.

Exploring the Future of Packaging Machinery with Thomas Dohse | Shanghai swop Interview

In this exclusive interview at Shanghai swop, we sit down with Thomas Dohse, a key figure from interpack, to dive deep into the future of packaging machinery and the emerging trends shaping the industry. Discover the fascinating highlights of the swop exhibition, including innovative technologies and unique insights into the latest advancements. Thomas also shares his perspective on the resurgence of globalization, which has taken a new form through fragmented and decentralized transactions, creating fresh opportunities for businesses worldwide. Finally, Thomas gives us a sneak peek into the 2026 interpack, unveiling its central themes and what we can look forward to in this global event. Don’t miss this insightful discussion that combines cutting-edge trends with a vision for the future of packaging!

Sheet Cutting Machine | YICHEEN

Description: Friendly interface, PLC computer touch-panel screen control system. Non-hydraulic design, no pollution, low noise, best for using in dustless room. Servo motor control feeding (for EVA sheet cutting tolerance +/-1mm). Modulating control for tension control, it keeps cutting stable. Anti-static PU roller drive for reducing scrape happened. Optional devices: Shaftless unwind stand (electrical left/right moving), EPC (Edge Position Controller), Slitter, Punching device (electrical left/right moving), Automatic stacker, Static eliminating device,

Proportional Valves for Plastic & Rubber Industry | KAO LU

KAO LU ENTERPRISES CO. is an professional Taiwanese manufacturer. With experience for over 40 years, it’s one of the leaders of the proportional pressure and flow control valves. With high-quality manufacturing techniques, their distributors spread all around the world. 【Video Outline】 Company Introduction Product Application & Competitiveness Product Introduction Main Customers Application on Medical and Biotech Equipment Application on Plastic and Rubber Equipment Advantages of the Era of Industry 4.0 Contact Information

Triangle Folding Machine & 1 Color Rotogravure Printing Machine | MING JILEE

Triangle Folding Machine, 1 Color Rotogravure Printing, MGA-27B-1000, MING JILEE Specializes in Triangle folding machine , Ming Jilee Enterprise Co., Ltd. established in 1987 and received ISO-9002 approval for Triangle folding machine and exporter. Our Triangle folding machine products are all as our business policy: high-tech quality, competitive price, best service, on time delivery, and more for sealing and cutting machine services.

Plastic Washing Machine | GEORDING

Plastic Washing Machine - Plastic Film Crushing Washing and 3IN1 Pelletizing Line - Waste Plastic Crushing & Washing Line 1000kg - GEOR-DING MACHINERY CO., LTD.. We specialize in manufacturing of Plastic Washing Machine. The main businesses include: Plastic Washing Machine and planning of entire plant’s equipment. While the demand for output and quality in Plastic Washing Machine worldwide is increasing day by day, our determination for upholding the motto, “Quality is number one. Output comes second. Customer satisfaction. Perfect service”, will never shift. Under your support and encouragement, we will continue to provide quality Plastic Washing Machine products and services to higher standards.

Blow Moulding Machine |FONG KEE

Blow Moulding Machine - High Speed Blow Moulding Machine-hba-ddgv-Fong Kee Specializes in Blow Moulding Machine, Fong Kee International Machinery Co., Ltd. (FKI) is the largest and finest Blow Moulding Machine manufacturer in Taiwan Plastic Extrusion Industry. Established in 1953 by founder C.C Wei and spread its business to over 100 countries . FKI manufactures variety of Blow Moulding Machine and etc. If you are looking for good Plastic Extrusion Machine Supplier, please feel free to contact us.

2023 Plastics & Rubber Indonesia On-site Tour | PRM-TAIWAN

Check our on-site tour video for Plastics & Rubber Indonesia 2023! Taiwanese suppliers, which is specialized in the Plastic & Rubber industry, known as its high quality machinery. If you don't want to miss out the latest news, stay tuned!

Online Exhibition - PRM Theme Pavilion | PRM What to Say EP6

Online Exhibition - PRM Theme Pavilion | PRM What to Say EP6 Are you still seeking appropriate suppliers under the unstable circumstance of COVID-19? We heard your concerns and heartfelt wishes for attending an online exhibition! Through PRM Theme Pavilion, without traveling abroad, you will have many opportunities to connect with the world. Now, we are excited to announce an upcoming new event PRM Theme Pavilion, which will bring you to the new horizon. In this video, we are gonna present what you will see in this online exhibition. This time, we will focus on showcasing manufacturers who are specializing in the packaging industry. Let's take a look at the PRM What to Say episode 6, where we are evaluating and introducing the next PRM Theme Pavilion which focuses on the Packaging industry. In the video, you will learn more about not only what this event is about, but also the benefit of the event for global visitors, how the event is planned and concentrated on a specific focus with the selected machine manufacturers and machinery lines that a packaging business all need.

Multi-layers Die Head Manufacturer at K 2022 | HSIN LONG

Hsin Long Thread Rolling Machine Co., Ltd. is knowing for high-quality products, such as blown film machine, extrusion die and extruder filter, and their post-sale service. By interviewing Ms. Sandy Chen, Production Manager, we gained the information about how Hsin Long apply digitalization in their equipment.

The Best Choice of Bag Making Machines | COSMO

COSMO has many years of experience in bag making machines. We are still willing to have much more improvement and all the consumers are satisfied with the quality of machines offered to you. 【Product Lines】 T-shirt Bag On Roll Making Machine Bag On Roll Making Machine T-shirt Bag Making Machine Garbage Bag & Industrial Bag Making Machine T-shirt & Bottom Sealing Bag Making Machine Side Sealing Bag Making Machine Air Cushion Bag Making Machine Stretch Rewinder Glove Making Machine 【Company Introduction】 COSMO Machinery Co., Ltd. established in March 2001, is well-known for Taiwan manufacturing plastic bag making machinery with servo driving systems. The product from COSMO has the servo motor as standard attachment, makes it easy to adjust the bag length and the production speed, computer control over the entire process, component self-testing function available, high production efficiency to save manpower and time. Up to now, COSMO products are extensively exported to 100 countries spreading all over the world.

Haitian Mexico Interview Part 1 | Current Situation in Plastics and Rubber Industry

Haitian Mexico Interview Part 1 | Current Situation in Plastics and Rubber Industry As PRM Media Channel, we had a video conference with one of the greatest Injection Molding Machine Industry from Mexico, Haitian Mexico! The Deputy General Manager of HAITIAN MEXICO, Jose Antonio Barroso, talked about the company’s profile and the current situation of COVID-19 in Mexico, the challenges they are having due to the pandemic, and their solutions to overcome those challenges.

3000 Ton Plastic Injection Moulding Machine | CLF

3000 Ton Plastic Injection Moulding Machine - Chuan Lih Fa CLF's Products: ⚫Via continuous challenging high-end injection machinery, CLF has success- fully invented the multi-circuit plastic injection machines, horizontal injection molding Machine, servo-driven hydraulic fully closed-loop controlled injection machine, multi-color/multi- resin injection molding machine, and etc. ⚫With our strength of machinery diversity, we could provide our customers the scheme of installment of whole factory buildings to achieve perfection of techniques and produc- tion capacity, and finally help them save the cost and shorten the investment cycle.

TPE, TPR, TPU Materials Explained | PRM What to Say EP12

In this episode, we will open a special page for TPU and TPE, TPR materials. Because there are several common confusions about them. Then, let’s understand the differences and fields of application of those innovative materials together. 【TPE/TPR】 Both TPE(Thermoplastic Elastomer) and TPR(Thermoplastic Rubber) belong to the family of Thermoplastic Elastomers, and there isn’t a defined industry standard to distinguish them. But, it is certain that TPE is made from SEBS, while TPR is made from SBS block copolymers. [TPE/TPR Applications] TPE/TPRs are great for anywhere that flexibility, comfort, or cost savings are needed. They are a top choice for medical applications like surgical and dental tubing and also tubing used in the food/beverage industry. 【TPU】 TPU(Thermoplastic polyurethane ) is a soft polyether type polyurethane that is available in a range of hardness grades, which gives a diverse application range to TPU. There are two main types based on soft segment chemistry: Polyester-based TPUs, and Polyether-based TPUs. [TPU Applications] With their resistance properties, TPU is superior for use anywhere that ozone, extreme temperatures, and high levels of abrasion are a concern. In addition to medical uses, TPU is also a popular material for sporting goods, tubing, wire, protective coatings, and more. All those materials above are alternatives for natural rubber and are easy to manufacture. Moreover, those materials can be 100% recycled.

All-Electric Injection Molding Machine | TAIWAN KINKI

TAIWAN KINKI(TKC) is pioneer of Vertical Injection Molding Machines for Auto Industry, we were the first in the world to design and manufacture the 1st all-electric vertical injection molding machine for Taiwan and China. TKC works with a wide range of plastic injection materials and molded parts. 【All-Electric Vertical Injection Molding Machine Features】 Low Noise:All process-relevant movements (injection, mold open/close) are executed via electric motors, resulting in quieter and less noisy operation. High Efficacy:The electric unit is digitally controlled so that the mechanical operation is highly repeatable and precise, and the electrical drive enables the parallel movement of the machine, so the process is faster and more efficient. Save Water:Fewer components and oil need to be preheated than hydraulic injection machines, thus saving on cooling water usage. Power Green Energy:No hydraulic system is used, and energy is only used during machine movement, so it can save more energy and achieve power green energy.

2023 Plast Eurasia Interview | WEI MENG

It's our great honor to interview WEI MENG and their Turkish agent in the 2023 PlastEurasia. Watch our video for more information!

Central Drum (CI) Type Flexo Printing Machine | PRINTPLAS

The central impression drum surface precise grind and coated, without risk of pores and with the dual wall design for water cooling purpose to ensure material to be smoothly transport and precisely printed. 80mm thick cast metal plate frame provide a very steady, vibration free foundation for the printing work. Servo motors equipped for main drive / in-feed /out-feed / unwind and rewind, provide a smooth motion control for constant tension for film. Servo motors driven auto impression setting for each printing station with memory pack. Anilox sleeve and plate sleeve system is quick change side insert type. Turret type auto splicing for unwind and rewind is non-stop to change the roll. Equipped with internet accessible control system for remote diagnoses of programming and electronic components. 【Company Introduction】 Printplas Machinery Co., Ltd have been established since 2001 and specialized on the manufacturing of CI & STACK flexographic printing machine in Taiwan. With skill workers and machine R&D department, we are keeping our effort for providing precise, stable, high speed printing machine for our users.