Video Description

In this episode, we will open a special page for TPU and TPE, TPR materials. Because there are several common confusions about them. Then, let’s understand the differences and fields of application of those innovative materials together.

【TPE/TPR】

Both TPE(Thermoplastic Elastomer) and TPR(Thermoplastic Rubber) belong to the family of Thermoplastic Elastomers, and there isn’t a defined industry standard to distinguish them. But, it is certain that TPE is made from SEBS, while TPR is made from SBS block copolymers.

[TPE/TPR Applications]

TPE/TPRs are great for anywhere that flexibility, comfort, or cost savings are needed. They are a top choice for medical applications like surgical and dental tubing and also tubing used in the food/beverage industry.

【TPU】

TPU(Thermoplastic polyurethane ) is a soft polyether type polyurethane that is available in a range of hardness grades, which gives a diverse application range to TPU. There are two main types based on soft segment chemistry: Polyester-based TPUs, and Polyether-based TPUs.

[TPU Applications]

With their resistance properties, TPU is superior for use anywhere that ozone, extreme temperatures, and high levels of abrasion are a concern. In addition to medical uses, TPU is also a popular material for sporting goods, tubing, wire, protective coatings, and more.

All those materials above are alternatives for natural rubber and are easy to manufacture. Moreover, those materials can be 100% recycled.

-

CHINAPLAS 2021 Organizer Interview | PRM Media Channel

CHINAPLAS 2021 Organizer Interview | PRM Media Channel

-

GENIUS MACHINERY: Innovation & Current Situation in the Plastic Recycling Industry

GENIUS MACHINERY: Innovation & Current Situation in the Plastic Recycling Industry

-

Plastic Thermoforming Machine - Fruit Container Box Machine | CHUDONG

Plastic Thermoforming Machine - Fruit Container Box Machine | CHUDONG

-

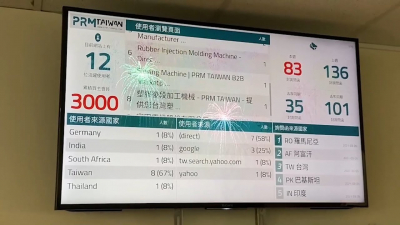

Thanks to 3000+ Members of PRM-TAIWAN B2B Platform

Thanks to 3000+ Members of PRM-TAIWAN B2B Platform

-

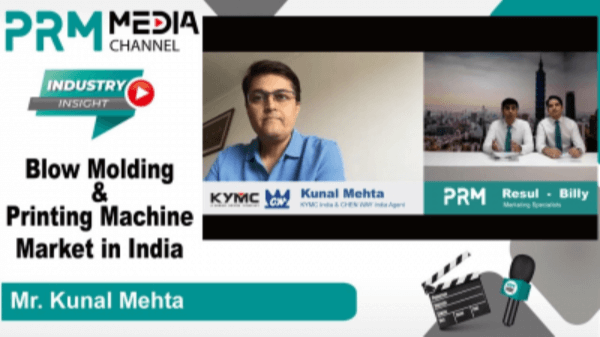

Industry Insight: Blow Molding Machine and Printing Machine Market India

Industry Insight: Blow Molding Machine and Printing Machine Market India