Liquid, Solid and Granule Food Packaging Machine Solutions | SAN TUNG Interview

At the last version of the TAIPEI PACK exhibition, PRM Media Channel had an interview with SAN TUNG MACHINERY. We invite you to take a look at the food packaging machine solutions and industry observation of SAN TUNG. In the video, you will find the on-site machine introduction of - Liquid Food Packaging Machine Solutions - Solid Food Packaging Machine Solutions - Granule Food Packaging Machine Solutions by the demonstration of Mr. Yao & Ms. Cathy. Moreover, Ms. Cathy is also sharing her insights into the current situations in the packaging industry, and her expectations of future cooperation with their clients.

2024 CHINAPLAS Interview | King Plus

They are the manufacturer of blown film machines. In the past thirty-five years, Han King has relentlessly accumulated vast experience, from manufacturing mono-layer machines to two-layer, three-layer, and five-layer machines. We develop and produce our rotary die, embossing device, 360-degree oscillating haul-off, internal bubble cooling system, automatic air ring, and other blown film machine components.

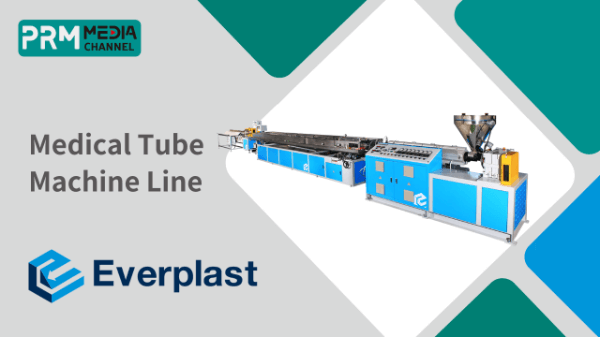

Medical spiral tube extrusion machine line (double output ) | Everplast

Medical spiral tube extrusion machine line (double output ) The medical tube, made by food-grade materials, with the advantage of high transparency, good elasticity, good fluidity and corrosion resistance, suitable for medical, pharmaceutical and food production of gas and liquid delivery pipes, etc. -Contact Info: Twitter: / everplast Facebook: https://reurl.cc/r1LZb Web: https://www.everplast.com.tw/ Tel: +886-2-2289-7271 / +886-6-201-4846 Fax: +886-2-2289-7282 / +886-6-201-4290 Email: [email protected]

Quick Mold Change System|Sistema cambio rápido moldes|быстрый mold изменение системы|SANDSUN

Learn more about the Quick Mold Change Systems : https://bit.ly/37ST04V Sistema de cambio rápido de moldes, быстрый mold изменение системы, السريع تغيير النظام العفن produced by SANDSUN Introduction of our Quick Mold Change System : It is an era for making high frequency mold changes with multiple patterns and small quantity. In order to save time for the mold change and ensure the safety of the operation, it is just in time to apply Quick Mold Change System. Sandsun safety function of Quick Mold Change System : ✔️Each hydraulic circuit has the function of checking and avoiding oil leaking. ✔️This system can add pressure automatically when the pressure reduction. ✔️Each hydraulic circuit has the function of inspection pressure and can be interlocked with the machine. ✔️It adopts the intersecting direction to clamp the mold. ✔️There are several functions to avoid operation error. Explanation of video content : Mold Change less than 2 minutes on 1300T injection molding machine 0:00 Quick mold change less than 2 minutes on injection machine 0:19 Pre-load the mold on the cart 0:23 Mold move out 0:36 Mold arrive in the position, and the cart start to switch position 0:49 Mold cart arrive in position 0:55 Injection machine adjust the stroke for mold automatically 1:04 Mold move in 1:21 Hook back to original point, door close automatically 1:28 Mold close, clamps lock the mold automatically 1:39 Protection rods rise, cart start to move 1:49 Cart back to mold hanging area, finish mold change

Mold Cart System Co-Ordinated with AGV for Plastic Injection Molding - Industry 4.0 | SANDSUN

Mold Cart System Co-Ordinated with AGV for Plastic Injection Molding - Industry 4.0 | SANDSUN Introducing automatic injection molding mold change carts system from SANDSUN in Taiwan, which is a leading global customized die and mold change cart system manufacturer. Please refer to the link above to learn about SANDSUN's detailed designs on the mold cart system, including functional advantages such as Hook Type, Motor Roller Type, Real Case, and Electric Mold Trolly. SANDSUN has been providing high quality, secure and efficient injection molding machine mold change cart systems to India, South Korea, Thailand, the United States, Vietnam, Malaysia, Mexico, Brazil, Russia, and many other countries at a reasonable and affordable price for many years. Thus, SANDSUN earned a good reputation in mold change systems and die change systems around the world. Features of die/mold cart system : Shorten the operation time of mold change. Auto position checking of mold changer moving. Automatically check the stroke of mold open, arrival, and positioning in the process of moving. Device for preventing mold sliding. Die / Mold Cart System co-ordinate with AGV : This video was shot at Chung Yuan Christian University in Taoyuan, Taiwan. The content is the collaboration between the automatic mold cart system and the automated guided vehicle (AGC). The combination of two high-tech devices effectively increases industrial production efficiency and achieves industry 4.0 goals. # SANDSUN Die Cart System Mold Cart System AGC Automated Guided Vehicle Fourth Industrial Revolution Industry 4.0 PRM Media Channel Hizli Kalip Degistirme Sistemleri Enjeksiyon Makinesi Kalip Degistirme

Waste Material Recycling Equipment at K 2022 | GENOX

It was a great honor for PRM-Taiwan to invite Jamie Jiang — the Marketing Director from GENOX. In the interview, we talked about the macro economic market during the pandemic, and the forecast for the future. In the end, Jamie also mentioned that the K Show is a worldwide exhibition for partners from the Plastic & Rubber industry, people can gain the newest industry information at the show.

Product Enhancement Through In-mold labels & Heat Transfer Films | XIANG IN

Have you ever wondered that your products do not look good and attractive? There is a simple way to enhance your product outlook and increase the quality and profitability. Throughout the interview with Ms. Penny, General Manager from XIANG IN ENTERPRISE, we have discussed advantages by using in-mold labels and heat transfer films to level up your products. Moreover, both of these two techniques not only be used in plastic, but also apply on wood, glass, metal and some particular materials. XIANG IN has been dedicated to developing its technique and improving their inspection. Therefore, the competitiveness of their products could not be replaced due to their strength of expiration and accurate quality inspection.

Fibrillated Tape Extrusion Line (JC-FYB) | PLASCO

PLASCO's JC-FYB Series of extrusion lines are designed to produce either standard or heavy-duty fibrillated tape for technical end-use applications, such as baler twine, insulated cable filler, carpet backing, synthetic grass, and more! 【Machine Spec】 Applicable Materials: PP / HDPE Screw Diameter (mm): 85 / 100 / 110 Denier (D): 3000-25000 / 3000-30000 / 3000-35000 Working Width (mm): 800 / 1000 / 1200 Extrusion Capacity (kg/hr): 120 / 200 /250 【Application】 Rope Cable filler Baler twine 【Company Intro】 PLASCO is a global industry leader in the design, manufacture, and supply of innovative plastic extrusion lines. They specialize in applying innovative engineering concepts to the design and manufacture of plastic extrusion lines with more than 30 year experiences.

Digital Transformation for Packaging Industry | Taiwan Packaging Association

In this video, we interview the new Chairman of Taiwan Packaging Association, Mr. Benker Liao. Throughout this video Mr. Liao introduces the importance of participation in the international exhibitions for the Packaging Industry and how it was affected during the pandemic. The new Chairman has encouraged the players of Taiwan Packaging Industry to make a change in mindset, organizational and business transformation for Online Marketing.

PVC Medical Tube Extrusion Machine Line (High speed type+Dust proof) | Everplast

The medical tubes produced by Everplast's medical tube extrusion machines have excellent quality and accuracy. They use advanced manufacturing technology and precision machining processes to ensure that each medical tube has accurate dimensions and uniform texture, complying with the strict standards and standards of the medical industry. specification. Whether used for infusion, drainage, or other medical applications, these tubings provide reliable performance and safety. Meets the strict quality and specification requirements of the medical industry. *Contact Info: Web: https://www.everplast.com.tw/ Facebook: https://reurl.cc/r1LZb YouTube:https://www.youtube.com/channel/UC_ziI3cDyRGjV71s8YkV-pg 1.https://www.everplast.com.tw/product/machine-line/medical-tube-machine-line/ 2.https://www.everplast.com.tw/product/machine-line/ 3.https://reurl.cc/QeMrp0 Tel: +886-2-2289-7271 / +886-6-201-4846 Fax: +886-2-2289-7282 / +886-6-201-4290 Email: [email protected]

YF Super Sealer | PRM Media Channel Interviews at TAIPEI PACK 2020

TAIPEI PACK once again is held in December 2020 at Taipei City, Nangang Exhibition Hall 1. PRM Media Channel was on the field to share insight into the packaging industry. During the exhibition, PRM Media Channel conducted an interview with Mr. Kevin Chang from YF Super Sealer (Y-Fang Group). We have talked about the current situation of the packaging industry during the pandemic, the new methods of the company to sustain efficient customer care. Moreover, Mr. Chang introduced the showcasing machine, which is designed especially for the take out food industry and ready food industry. Let us know your opinion and the inquiry in the comment section. Stay tuned for the forthcoming interview videos and remember to subscribe to our social media channels for similar videos!~

How to select anti-blocking agent for plastic masterbatch? --Please keep these 4 points!

Homsil special silica for plastic masterbatch is a mainstream and high-effective anti-blocking additive. It gives excellent performance to PP/PE/PET/POF and other plastic material anti-blocking masterbatch, co-made film by the masterbatch carrier. Widely used to Aluminized film, cigarette packaging film, heat shrinkable film, fruit bagging film, general packaging film, etc..Comply with FDA regulation, REACH regulation and other relative food contact requirements. Safe and healthy!

Yaodong Machinery Highlights Packaging and Printing Integration for High Efficiency and Low Cost Benefits (Chinese Interview)

Yaodong Machinery Manufacturing Co., LTD is a high-tech enterprise that specializes in designing and manufacturing automatic screen printing machine, hot stamping machine and the peripheral equipments related. The R&D Team is over 20 years industrial experience, adhering to expertise, efficiency, honesty, win-win is our philosophy, committed to create value for customer and offer comprehensive solution. Professional technology leads to our success; we will continue to innovate to promote the automation and intelligence of products, fully integrating auto loading, flame detection, CCD registration and detection, UV intelligent management, temperature and humidity synchronization monitoring and other function modules, continuous to provide high quality, stable and high performance products and supporting solution. “Advanced technology, quality first, service superior” is the central theme to win the reputation. We have serviced to lots of famous brand domestic and abroad, such as P&G, Amore Pacific, Unilever, LG, Loreal, Henkel, Kao, NIVEA, Reckitt Benckiser, Avon, Johnson & Johnson, Shiseido, Mentholatum, Pechoin etc..

Expanding Polymer Horizons: OQ Committed to Innovation and Sustainability of Polyolefin (Chinese Interview)

OQ is a global integrated energy company with roots in Oman. It emerged in late 2019 upon the successful integration of nine legacy companies, united to form a stronger, more efficient, and consolidated entity. We operate in 17 countries and cover the entire value chain in the hydrocarbon sector from exploration and production, to marketing and distribution of end-user products. Our fuels and chemicals are sold in over 60 countries worldwide. We also partner with local and international companies in the hydrocarbon sector to increase value for the shareholders and reap greater benefits for the communities.

Leading Global PEEK Company Victrex Reinforces The Presence and Capacity for China and Asia

Victrex is an innovative world leader in high-performance polymer solutions, focused on the strategic markets of automotive, aerospace, energy, manufacturing & engineering, electronics and medical. Every day, millions of people use products and applications, which contain our materials from smartphones, aeroplanes and cars to oil and gas operations and medical devices. With over 40 years experience, we develop world leading solutions in PEEK- and PAEK-based polymers and selected semi-finished and finished parts which shape future performance for our customers and our markets.

Donghua Machinery's High-precision All-electric Machine for Medical Applications Debuts, Chemical Foaming Promotes Automotive Lightweighting (Chinese Interview)

Donghua Machinery Ltd. is a subsidiary of Cosmos Machinery Ltd., the Hong Kong joint venture enterprise for manufacturing full-automatic computer-controlled injection moulding machines and auxiliary equipment. Donghua was founded in 1986, Donghua can provide a whole set of injection moulding machine and its auxiliary equipment to customers on turnkey basis, with 43g to 300,000g injection volume, 25T to 4,000T clamping force, totally in over 90 models with various design specifications. The yearly output capacity is over 5,000 machines.

Multitech's Injection Molding Modularization Accelerates The Delivery of Automotive Electronic Precision Parts (Chinese Interview)

Multitech Machinery specializes in manufacturing Vertical Precision Injection-Molding Machine, LSR Injection Molding Machine and Injection-Unit for multi-material product and focuses on technology developing to service Turn-Key solution to customers. Multitech was founded in 1994 as a machine service company. Through development, the factory, covering over 10,000 square meters is built in Shenzhen on September 2002 and recruits more than 200 employees; engineers and senior technicians account for 50% of all team members. After decade improvement, Multitech gains ISO9001 certification, CE certification and entitle with National High-Tech Enterprise in 2013.In 2018, Multitech Park is unveiled to world with covering 30,000 square meters facility, equipping modern CNC machines and world-class management system. With elite team in R&D, manufacturing, service and marketing, Multitech is devoted to be the professional manufacturer and be the global leader in special Injection Molding Machine.

FCS Presents Multi-color Injection Molding for Automotive and 3C Electronics (Chinese Interview)

FCS Group, based in Taiwan, was founded in 1974. And it was listed on OTC in electrical machinery category in 2004, as well as a provider of precision plastic injection molding technology services. FCS owns a professional team to excel in Injection Molding Machines, mold, plastic, molding technology and other fields to provide total solutions in customization and automation (systematic) of production equipment to meet customer requirements. For more than forty years, FCS IMM has built a very good reputation for its machines' high quality and excellent functions. The FCS World Marketing and Servicing Network rapidly and efficiently support customers' need. We have established three Sales & Service Offices in Taiwan, more than thirty ones in China, and have approximate forty agents all around the world. There are hundreds of professional technicians standby to serve FCS customers.

HSIN LONG Blown Film Die Heads | CHINAPLAS 2021

PRM Media Channel is very glad to announce the great cooperation with CPRJ, the official media group of CHINAPLAS. For this great opportunity, we bring you one of our special actors in the Blown Film Die Head Industry to share with us important facts & insights into the industry, and how their expertise reflects an outstanding performance on customer service, manufacturing process, and quality field. With half a century of rich experience in manufacturing, HSIN LONG is mainly specialized in producing Blown Film Dies and related components. These components can be applied in Packaging Films, Barrier Films for food packaging, Technical Films for high-tech applications, Sealing Films, Agricultural Films, Medical Films, Shrink and Stretch Films, TPU Films, Biodegradable Plastic Bags / Green Plastic Bags, and many more. In this video, our PRM Marketing Specialist Billy will be carrying the interview with the Special Assistant to the GM, Sandy from HSIN LONG Thread Rolling Co.

Leading European PA Supplier DOMO Accelerates Strategic Development in Asia Pacific (English & Chinese Interview)

Domo Chemicals is a leading producer of high-quality engineering materials and versatile plastics for industrial and consumer applications in a diverse range of markets, including the automotive, food, medical, pharmaceutical, chemicals and electronics industries. The company offers a complete portfolio of integrated nylon 6 and Nylon 66 products, including intermediates, resins, engineering plastics and packaging filmand distribution of petrochemical products. Headquartered in Germany, the family-owned company leverages advanced technology and consumer insights to deliver sustainable & innovative solutions.

JCtimes Debuts 2.5D Algorithm to Revolutionize Multi-layer Co-extrusion (Chinese Interview)

JCtimes Group dreams of what customers dream and pursues a globalized brand strategy. Owning three brands Jingcheng, JCTIMES, and Goodee, JCtimes Group has dedicated to the production, application, and R&D of extrusion dies and auxiliary equipment, and achieved over 70% domestic market share in China’s high-end market. JCtimes, a world-leading brand in the global flat-dies extrusion industry, has focused on the development of new materials, technology, and technique for more than 20 years. Key technical advantages in flow channel simulation system, five-axis processing, and precise grinder provide integrated solutions in sheet, foil, and film material fields. The products have been widely applied in electronics, automobiles, building materials, optics, new energy (solar energy, hybrid vehicles, lithium battery), health care, food packing, and other life aspects.

Haitian Shows Machines for All-electric and Thin-wall Injection Molding Trends (Chinese Interview)

HAITIAN INTERNATIONAL HOLDINGS LIMITED Haitian International Holdings Limited develops and produces the international machine concept of the 21st century. Our sophisticated product portfolio of injection molding machine construction covers the entire spectrum of the plastics processing industry and meets the most diverse customer demands for the manufacture of mass and high-precision plastic products.

Blown Film and Recycling Machines - POLYSTAR | CHINAPLAS 2021

PRM Media Channel once again happy to share the great honor of the cooperation with CPRJ, the official media group of CHINAPLAS. Through this cooperation, we aim to provide insights into the Plastics and Rubber industry by the sharing of experts. In this video, we have invited Mr. David Lo, Chief Marketing Officer, to share his knowledge and the overview of Blown Film Extrusion Machines and Plastics Recycling Machines markets. POLYSTAR Machinery is one of the most famous manufacturers especially in recycling machines in Asia with more than 30 years of experience. Besides recycling machinery, the company also well known around the world with its blown film machine lines. Most of the customers of POLYSTAR buy several sets of blown film machines as well as recycling machines together to set a complete line in their factories and contribute to the circular economy. In this video, Daniel from PRM will be carrying the interview with the Chief Marketing Officer Mr. David Lo. During the interview, Mr. Lo is explaining the advantages for the customers having both blown film machines and recycling machines from POLYSTAR. The following, interview covers several topics including: 1. Advantages of POLYSTAR recycling and blown film machines 2. POLYSTAR contribution to circular economy and examples 3. Simplifying machine design for ease of use 4. Vision and development in 2021

Three Systems for Thermoforming Machines - CHUDONG | CHINAPLAS 2021

PRM Media Channel continues with this great cooperation we began with CPRJ, the official media group of CHINAPLAS, providing insights about Taiwanese experts in the Plastic and Rubber Industry. In this specific case, we had the great opportunity to interview one of our special actors in the Thermoforming Machinery Industry who will give us some great insights of the related industry. CHUDONG Machinery is a professional manufacturer with more than 35 years of experience in manufacturing & developing thermoforming technology and services in forming, cutting, and stacking in one place. The core for growth and success according to CHUDONG is having a strong R&D that can create specific systems to different markets. In this video, our PRM Director Alice will be carrying this interview with President Chester Chen & Vice-President Sophie Lu from CHUDONG Machinery Company. In the following President Chester Chen & V.P. Sophie Lu will be covering more about the three systems for air pressure thermoforming machines for the European, Japanese, and Asian markets: 1. Three Systems for Thermoforming Machines 2. Key Factors for Product Development 3. Differences between these Three Thermoforming Machine Systems 4. 2021 Innovations and Developments 5. CHINAPLAS Exhibition 2021

Jwell's high-speed and high-efficient blow molding technology accelerates packaging development (Chinese & English Interview)

SUZHOU JWELL PLASTIC MACHINERY CO., LTD. Suzhou Jwell blow-molding machinery is another important strategic development center of Jiangsu Jwell plastic Machinery Co., LTD, located in Suzhou Taicang FOSHAN BEKWELL INTELLIGENT EQUIPMENT CO.,LTD. Foshan Bekwell Intelligent Equipment Co.,Ltd. is another important development strategy center of Shanghai JWELL Machinery Co.,Ltd. Locating at Lunjiao sireet Shunde district Foshan City,a high-tech manufacturer specializing in research and development of plastic extrusion equipment. The factory area is of 30 acres, more than 100 staff and 20 technical and management employees; We have a high qualified R&D and experienced mechanical and electri-cal engineer team as well as advanced processing foundation and normative assembly shop. We supply more than 200 sets lines annually. Our enterprise spirit is "Attentive, Enduring, Quickly and Orderly", keeping on exploring of new extrusion field. Mostly welcome to new and old customers to visit us for investigation, guidance and cooperation. We are happy to offer powerful support!

Victor Machinery Launches All-electric IBM Machine with World's First Full Circle In-mold Labeling (English & Chinese Interview)

Jiangsu Victor machinery co., LTD., is a collection research and development, production, sales and service in the integration of science and technology innovation enterprise.Main products injection blow molding machine and precision mould, plastic extrusion sheet production line, ptfe extruding production line.As a professional plastic packaging processing equipment suppliers, Victor machinery has been committed to become the trustworthy partner for customers, provide the comprehensive consummation production solutions.

Increase of orders: Jwell promotes new plates, sheet and film equipment (English & Chinese Interview)

CHANGZHOU JWELL PLATE & SHEET EQUIPMENT TECHNOLOGY CO., LTD CHANGZHOU JWELL PLATE & SHEET EQUIPMENT TECHNOLOGY CO., LTD. is one more important strategic center and production base of JWELL Group.As the leading enterprise in plastic sheet machinery industry,. It is a company be specializing in manufacuturing optic sheet and waterproof sheet extrusion equipments.We have different department which include technical d, this new factories are equipped with a lot advanced CNC machining centers and well-organized assembling workshops. Every year, there will be more than 800 intelligent extrusion equipments manufac tured from this production base.Changzhou Jwell Sheet & Film Equipment Co.,Ltd is focus on manufacturing Sheet & Film extrusion equipments, complete and professional technical service, we are dedicated to offering Customized extrusion equipments for our global customers. Rigorous technical design, Strict and standard production process, complete after-sale service and maintenance system, ZHEJIANG JWELL is providing high-efficiency,energy-saving, outstand ing-quality extrusion eqipments and caring service to our customers. CHANGZHOU JWELL CHEMICAL MACHINERY CO., LTD. CHANGZHOU JWELL CHEMICAL MACHINERY CO., LTD. is a professional company of Jinwei machinery with the main business of parallel twin-screw. For many years, CHANGZHOU JWELL CHEMICAL MACHINERY CO., LTD. has been committed to the production and research and development of co rotating parallel twin-screw main machine and supporting auxiliary machine, and has achieved the same level in the application of polymer materials, such as all kinds of high filling granulation, PET bottle and other recycling granulation, PLA / PBAT modification and filling granulation, polyurethane / TPU reactive extrusion granulation and other mainstream technologies required by market application Head to head and ahead in some technologies. SUZHOU JWELL MACHINERY CO., LTD. Suzhou Jwell Machinery Co., Ltd. is an important development strategy center and manufacturing basement under the JWELL GROUP. It is located in Chengxiang Industrial area, Taicang, Suzhou City, 30 minutes far from Shanghai Hongqiao Airport. It covers an area of 20 hectares, and the workshop area is 120000 square meters, equipped with CNC machines and standardized assembly workshop. More than 1000 employees, with high-quality design and R & D team and experienced mechani cal and electrical commissioning engineer team. The company focuses on the manufacturing of the plastic pipe extrusion equipment and the full range of professional and technical services and turnkey project, making top quality plastic extrusion equipment to the customers of the world, which accounts for more than 75% is export. Strict design, strict standardized manufacturing process, perfect after-sales service guarantee system, provide customer with high efficiency, energy saving, excellent quality extrusion line and intimate service.