Top 3 Advantages of Plastic Pallet Injection Molding machine

Plastic pallet injection molding machines are changing a revolution in industry. The conventional concept of wooden pallet is being replaced with the plastic pallet injection machine. Also, the emergence of new plastic pallet machines to change the traditional concept of the pallet can not only increase the production efficiency but also reduce the space occupied and be friendly to the environment.

Let's look into the top 3 advantages of plastic pallet injection molding machines.

1. High rigidity, stable clamping system

Through stress analysis, we ensure the structure's strength. With 4 clamping hydraulics, a stable and accurate clamping system, it can reduce the deformation of mold. Besides, with long moving platen to support the base, the clamping movement could be more smooth and stable. Also, it can keep the accurate degree of parallelism to avoid mold forward tilting.

2. A faster speed of mold changing

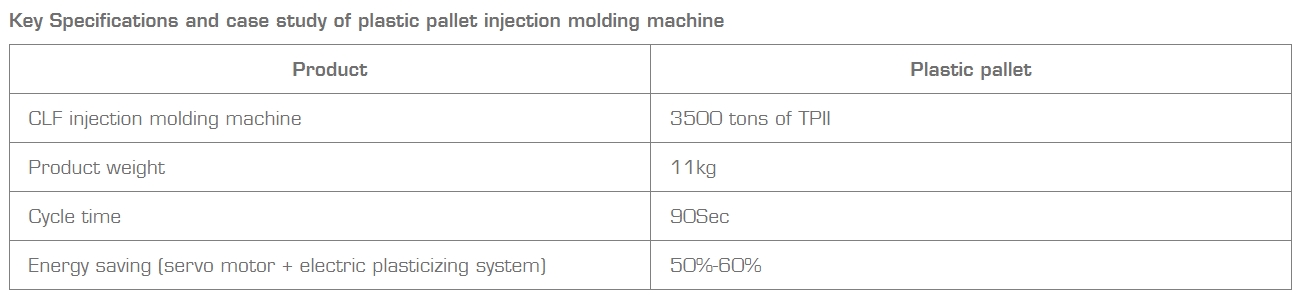

With a special structure designed by CLF, the TPII's Injection Molding Machine could give a better and faster process of changing mold. For those manufacturers who need small-volume large-variety production, TPII plastic pallet injection molding machine is their ideal choice.

3. Flexibility of customization

The plastic pallet injection molding machine with two-plate design offers greater flexibility for customization than other machines. Additionally, for factories with limited space for molding from the top, TPII injection molding machines provide the option to exchange molds from the side, allowing for more space and a more featured design. This makes for a valuable investment for plastic pallet manufacturers.

One success story involves a partnership with a leading Taiwanese brand of plastic pallets. The company requested improvements to the cooling system design and a shortened product cycle time. Based on their needs, the design was adjusted to improve cooling efficiency. Testing yielded positive results, with a decrease of approximately 40% in cycle time and the ability to produce an 11 kg plastic pallet in 90 seconds.

In summary, the increasing demand for plastic pallets presents a challenge for manufacturers to improve their production efficiency. Using recycled materials and eco-friendly systems not only saves energy and costs, but also demonstrates a commitment to sustainability. Optimizing the design of molds or cooling systems and reducing cooling time can help shorten the product cycle time. However, for a complete production solution, the TPII series may be the most valuable investment.

Currently, CLF is focused on R&D, manufacture and sales of plastic injection machinery, and is known in the market for its super-large, high precision and high performance plastic injection molding machines. Upholding the spirit of pursuit of excellence and sustainable innovation, CLF has never halted its progress in the development of plastic injection molding technology.

Due to market demands and expansion of business, in addition to the R&D headquarters in Taiwan, CLF also has a manufacturing plant in Zhongshan City, Guangdong Province, China, which is highly productive. CLF machinery has excellent quality and is very stable, sold globally to over 40 countries.

From the force to pushing the world forward to nurturing cornerstones of innovation, CLF firmly believes that frequent changes will create the extraordinary. We are happy to invest resources, nurture talents who are willing to innovate, with heavy involvement in the field of plastic injection molding, to break new grounds in creating technology that is truly global.