Xiang In: How Is Having A Quality Labeling Design Increases Your Final Product’s Value

Nowadays, most of the products that we consume on a daily basis contain different kinds of labels promoting a brand or a message to its consumers. Xiang In Enterprise is one of the biggest manufacturers, with two decades of expertise in the industry, specialized and dedicated to the manufacture of heat transfer machines and films and in-mold labels (IML). In the Labeling Industry, they are considered one as the makeup artists for customers’ products, meaning they are capable to customize and design according to the customer needs. Xiang In products gives 5 different and essential benefits to its customer:

1. Durability

2. High Printing Quality

3. Lower Production Time and Costs

4. Hygiene

5. Environmentally friendly

When we compare both the IML and Heat Transfer Films, we see its usage has the same range of applications, but applied in different ways. The Heat Transfer Films is widely used on wood, iron, glass, and plastic products. The main plastic products of heat transfer films are used in PP, PE, LDPE or other hard plastics, such as ABS, Acrylic and Tritan. However, IML is currently only used in plastic products, PP and PE.

|

|

|

| In-mold Label | Heat Transfer Film |

The advantages of Xiang In’s production methods do not only come on their machines, but on its technologies as well. Through its technology, it is expected to have a yield rate as high as 95% to 98% on their labels. Unfortunately, this is commonly neglected by customers. Let's say if the quality of IML and heat transfer film are defective, it would not only cause the loss of labels, but also the loss of the whole unit of product because the cost of the product itself may be ten or even a hundred times higher than that of the label. Many parts of the production process are manually inspected, which is a quality control step that cannot be achieved by machine. As a result, customers do not have to worry about the high damage rate of the product and high costs. If the customer does not know how to evaluate the loss rate of their product, Xiang In is willing to provide a formula to calculate it.

At present, Xiang In is committed to follow the global trend to make the application of recycled plastics wider because many countries currently require all plastic products to be recycled. When the plastic injection uses the recycled plastic, its surface becomes very rough and looks cheap. Moreover, when recycled materials are re-processed, it will lose all luster and make it difficult to do printing on the surface. Therefore, IML and heater transfer films are applicable to those kinds of recycled materials. If you use heat transfer film and in-mold label for surface coating, it can be restored to a brighter and more beautiful product. What’s in it for the customers? It saves their production costs, and the final products' appearance becomes much more attractive.

Xiang In’s success rate has been more recognized around the world and this success has given them the opportunity to gradually expand to different international markets, such as: Southeast Asian countries, Asia, Europe, and the United States.

We welcome you to visit XIANG IN official website and inquire about their labeling films and machines you are interested in. Their specialist team will help you find and develop the most suitable choice for your production.

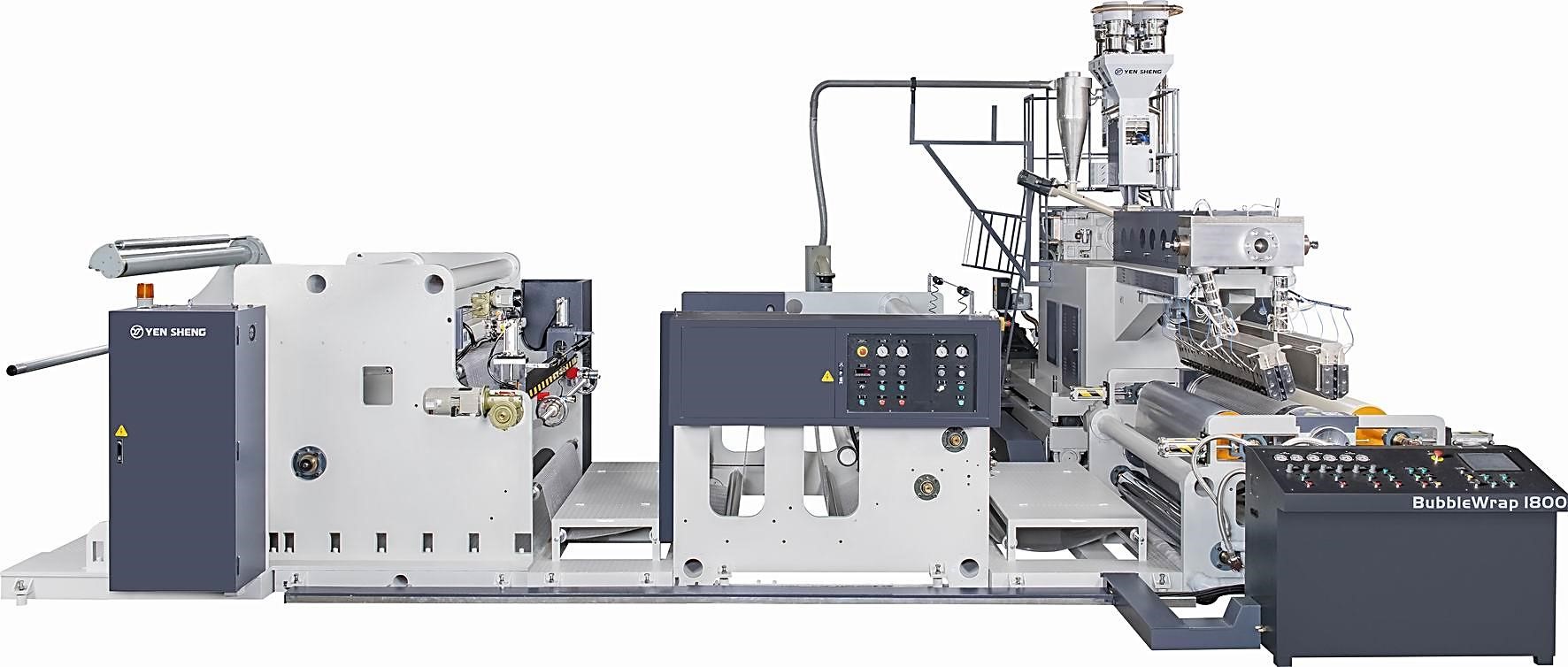

Xiang In Enterprise Co., Ltd was founded in 1997, and has been dedicated to manufacturing and developing of Heat Transfer Film,In Mold Labeling, and Heat Transfer Film Printing Machine. The aim of our company is to assist the clients and to develop sustainable operation to tend diversification development. With a belief of “Good tools are prerequisite to the successful execution of a job”, therefore we have equipped with the latest 10-color and 9-color gravure printing machines to accept multicolor requirement; we also have automatic cutting machine which can offer customer cutting service.

In addition to the manufacture of materials, we also customize the heat transfer machine to meet the clients’ vary requirements, as well as provide the technical assistance. We insist on taking strict inspection management for offering customers excellent quality products, these insistence not only reduce the following processing loss, also enhance the product competition in the worldwide market. Pursue high quality it's not enough for us, our delivery time is short and prompt for satisfying the customer’s request which can keep customer free of worry for delaying, make customers can contentedly recommend our printing to everyone.

We have been holding the spirit of turning the manufacturing industry into the service industry, and with the management philosophy “Superior quality, New product development, Serve Clients” as our principles. We look forward to collaboratively creating innovate business opportunities.