WINDER

Categories : Slitters and Rewinders

Winder is installed on the calender production line or on the end of production line that carries out exchange or rewinding various materials, in response to different winding requirement according to the products. Our winder adopt precise guidance and easy to operate. The speed is up to 200 m / min, the reel diameter is up to 1500mm, width is up to 6000mm. Some models are capable of reeling the upper side of films into the inner or outer roller. And after cutting the film into the desired specification, up to 3 rollers from the single spindle can be done. Processing with the drive motor and control system, the maximum tension precision at high-speed is guaranteed. We have a broad selection of winders for different product layout or custom. Automatic center winder (taping or Free taping type), automatic single roller surface winder, multi-roller surface winder; auxiliary equipment (trimming cutter and central cutting device, roll unwinding equipment and weighing unit, automatic roller puller), etc.

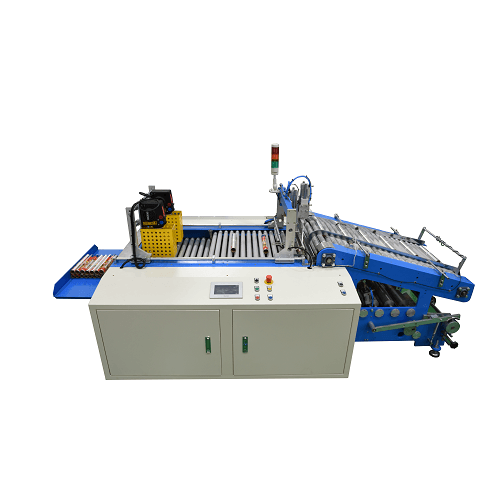

AUTOMATIC SHRINK FILM PACKAGING MACHINE (TPG 50)

Categories : Slitters and Rewinders

Model TPG50, the automatic shrink film packaging machine. A special design for wrap roll products. It can be connected to the back side of rewinding machine as an automatic production line. You can not only make your product refined and protected, but also arrange manpower more effectively. TPG50 is carried 3 conveyors as 3 work areas. It uses conveyors to deliver products to the processing area. You can choose automatic feeding of the material,or feed by detected sensor. As shrinkable films, BOPP, PVC and PE can be used on TPG50. The length of over wrapping film can be set manually or detected by the mark sensor. For packing decoration, you can use printed film; or, equip with a label paper device. The device will insert a piece of label before shrinking. The label will be wrapped inside the film, makes your product eye-catching. The last step, electrostatic device and thermal-wind will perfectly pack your products! Welcome to consult machine with us, we will at your service.

Polarizer Bonding Machine GFL-20

Categories : Extrusion Lamination Machines

High Rigid Body Design: Higher workpiece machining accuracy. More stabilized bonding range. Higher accuracy. Smooth Bonding Process: The bonding process has been carefully designed in providing safe interlocking and higher yield rate. Automatic Film Stripping Mechanism (Optional): Automatic bonding film stripping mechanism in providing stabilized action and higher efficiency. Patented Bonding Mechanism: Special bonding mechanism is designed to achieve higher bonding accuracy and air bubble free effect.

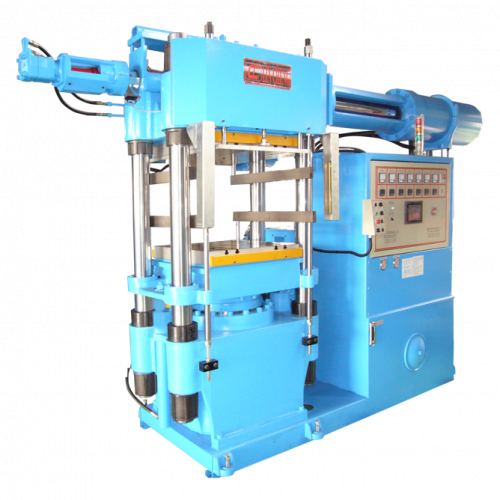

Up-Down Rubber Injection Molding Machine

Categories : Rubber Injection Molding Machines

Features Injection volume control High precision optical ruler is adopted for precisely calculating and controlling. Design of rotary injection board Special designs for loading/unloading functions are provided. It causes no dead material in the injection nozzle. It is easy to clean the material. It is durable and the quality is stable. Safety design A high-tech infrared safety electronic sensor and automatic warning system are adopted to monitors the status of machine in order to provide extra protection to ensure the operation safety for operators. Hydraulic system Design Hydraulic system Designed by proportional pressure and flow ratio, which is steady, quiet and low frequency of malfunction. Two shafts can be operated simultaneously.

DG-B Series Special-Purpose Bmc Injection Molding Machine

Categories : Automatic Injection Molding Machine

BMC is material mixed by unsaturated polyester, filling agent, coloring agent, releasing agent, catalytic agent and glass fiber. Not only with excellent heat- resistant, mechanic character, electric insulation, stable contractibility, suitable for any electric products of no-fuse-breaker, but also with high intensity, exact size, outstanding appearance, suitable for OA products as copy machines or printers, audio spare parts and car light-housing, etc.

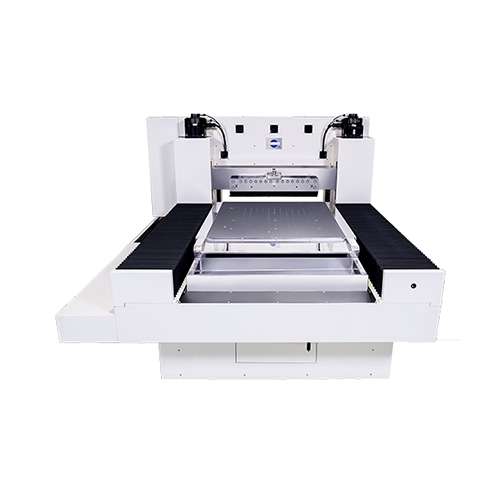

Coating Equipment Sheet To Sheet Coater

Categories : Inspecting and Testing Equipment

Slit Die coating on sheet substrate to check the coating thickness and uniformity. SUITABLE APPLY TO Water Base /Oil Base / Non-Solvent Type Liquid

Fiberglass Products Forming Machine

Categories : Compression Molding Machines

• Down stroke design with lower working height. • Double stations with the sliding carts increase productivity. • Sliding carts with position pins to secure working safety.

All Electric Automation Composites Forming Machine

Categories : Compression Molding Machines

Designed with independent ceramic heating system for quick materials preheating. Equipped with heating and cooling system to meet the different forming process, the key to make TPC products with high surface requirement.

Bimetallic Cylinder

Categories : Screws and Barrels

With a view to up-grade and achieve better stability in quality products, TAN STAR MATERIAL CO. LTD. had undertaken great efforts in the field of research and development in order to reach this goal. Since our Co. had gained ISO 9002 certification in the year 1997, we have continued to acquire modern equipment to improve the manufacturing process of our bimetallic barrel and screws. In order to resist the halogen free fire retarding agent for plastic, now Tan Star raises the tungsten carbide percentage to strengthen the ability of anti- corrosive and anti- abrasive. The best new one we called T-60.

TH Series-850/950/1100w

Categories : Industrial Robots

‧3Asix servo drive ‧Pick up time :0.5sec,Cycle time:2.9 sec ‧Huge traverse chain ensure cable/tubing durability ‧Motor thermal design long durable life ‧Full colour touch screen controlle

MULTI-LAYER AUTOMATIC FEED CUTTING MACHINE VAC-310

Categories : Foaming Machinery

Double-Axle Synchronous Pressurizing Mechanism: Performs the pressurization with double output axle to provide powerful and stabilized pressurizing capacity. Automatic Feed Mechanism: Uses servo control to carry out the setting according to the breadth and length of the material. Alignment Mold System: Performs concurrent cutting process after locking the material in place. Parameter Storing System: Performs module-based memory for the production figures to facilitate the parameter management. Cutting Plate Turntable Mechanism: Sets the offset length to achieve over 95% of plate utilization rate after cutting. High-Efficiency Boosting Circuit: Reduces over 30% of power consumption as compared to conventional circuit.

Composites Compression Forming Machine (Down Stroke)

Categories : Compression Molding Machines

Shuttle mold by sliding cart with smooth and precise movement. Downstroke design with lower working height. Special tilt angle for different mold design.