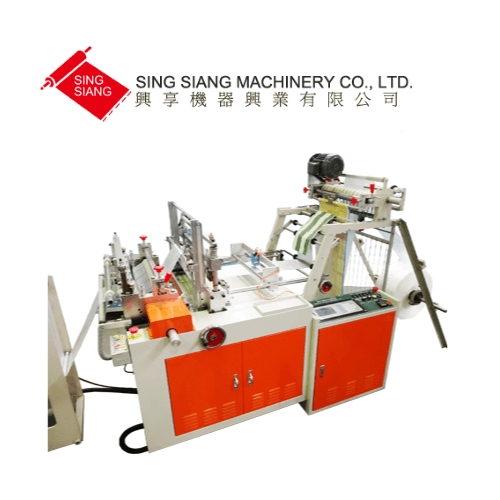

Bag on Roll Machine With Automatic Rewinding Module and Auto Labeling

Categories : Bag Making Machine by Applications

1. Servo Motor Driven, Efficient mechanical structure From film to final bag, one process flow. 2. Unique designed Multi-Functional Folding Device can fold three types of bags. 3. Adjustable Multi-Functional Folding Device can fold any size of bag without changing the rack. 4. This can produce Coreless Rolls. 5. User-friendly Control Panel, easy to understand easy to operate. 6. Digital control for production length adjusting, precise and less wastage. 7. Simple design, assemble precisely, durable, and easy for maintaining. 8. Easy operating, Pleasant cutting and sealing, with high firmness and no scratch. 9. Real time printing tracing control for accurate registration, when printing error occurred machine will stop automatically. 10. High production efficiency to save labor and time.

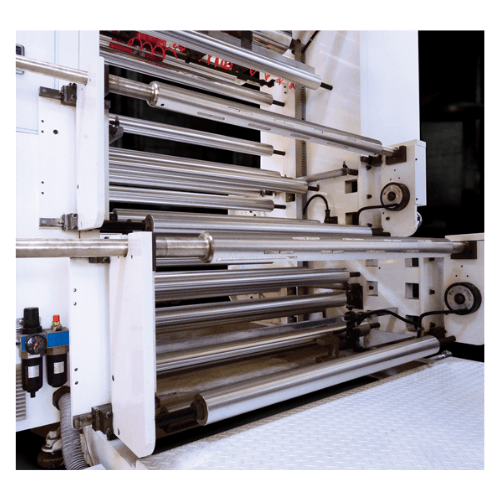

EPC - Horizon

Categories : Flexo Printing Parts

The Horizon type is Europe system made in Italy, this product automatic control the edge position to the right position by horizon move, which can be used on single colour flexo printing machine, ,two colour flexo printing machine, 6 colour flexo printing machine, flexo printing machine for corrugated carton, flexo label printing machine and other flexo printing machine.

40B96 Indicators and Alarm Units

Categories : Indicators and Sensors

Strain-gauge or potentiometer input -configurable by faceplate Sensor supply check Easy to calibrate with sensitivity auto-ranging Protected by a personal code Configurable by serial link Internal linearisation for engineering units Labels provided for the more common physical units Sampling time and trip intervention programmable between 15 and 120msec with resolution between 4000 and 30000 steps Retransmission of the measured variable signal 4 trip points, completely configurable from the faceplate 6 wires calibration o Version for magnetostrictive sensors

Doctoring Machine - REF-Q Series

Categories : Inspecting and Testing Equipment

Application and Materials: PVC shrinkable label tube

In-Mold Labeling Molds

Categories : Control Equipment

Varied items with In-Mold Labeling application available.

Wrap-around Labeling Machine KWT-500-Serials

Categories : Labeling Machines

KWT-500 serials are manufactured for round containers.

OPP/BOPP Labeling Machine For Square & Round Bottle -Automatic High Speed

Categories : Labeling Machines

1. Application for labeling round and square shape containers. 2. Fully automatic rotary operation for 330ml-4000ml bottles.(with certain change of parts). 3. Machine frame made of stainless steel 304. 4. PLC electronic control, touch screen monitor and electronic speed control(frequency inverter). 5. With a star-wheel carrying containers firmly while dispensing , provide stable dispensing performance under high-speed operation. 6. Use servo motor to synchronously tracks label supply, label cutting and use specially designed vacuum drum to ensure precise labeling. 7. Three-phase PLC and AC variable control with a synchronized tracking and control system to maintain label cutting accuracy in different running speed. 8. Centralized lubrication system for easy maintenance. 9. Detecting in feed situation with sensor, automatically adjust labeling speed according to feeding situation of production line, making production line coherent. 10. System safety device: when malfunctions such as irregular torques and abnormal feeding occur, machine will automatically stop for operation safety and machine durability. 11. Automatic label proofread system controller made in Germany. 12. Automatic speed self adjustment to contact other machine.

Secondary Packaging - Labeling - ABL-M

Categories : Labeling Machines

The labeling equipment is suitable for glue type labels. The entire equipment is mechanical controlled system to stabilize machine operation and output productivity. Minor parts change and simple adjustment is necessary for different products to be convenience to machine application.

In Mold Label (IML Label)

Categories : IML

In-Mold label (IML) is widely used in food container because the ink is between two layers of film and normally produce in dust-free fab or air conditioning clean room to minimize the human touch. Using IML can do the injection and labeling the product at the time. So it is suitable for mass production and standardization.

Bottle Filling Machine

Categories : Labeling Machines

FEATURES : 1. Made of SUS#304 corrosion resistant stainless steel and aluminum alloy 2. Filling volume and speed can be adjusted easily PLC control system with HMI touch panel for easy management 3. Memory storage of 15 to 20 sets for future usage 4. Ball-valve shut-off nozzle prevents liquid from dripping down 5. Dipping nozzles can prevent spillage and diminish bubbles 6. Capacity depends on filling nozzles, product and volume. 7. Machine is customized 4 - 12 filling nozzles. 8. It can be optional combined with the capping machine, labeling machine, shrink machine… 9. Piston pump filler is standard equipment, servo filler is optional. APPLICATIONS : Shampoo, Engine oil, Motor oil, Hair condition, Lubricant, Water, Sauce and other liquid or paste products …..etc..

LVDT displacement sensor

Categories : Indicators and Sensors

Differential transformer displacement sensor (LVDT) can be widely applied in aerospace, machinery, construction, textile, railway, coal, metallurgy, plastics, chemical engineering and scientific research institutions and other national economic fields to measure linear displacement, elongation, vibration, object thickness, expansion and on the like. The product has the characteristics of no-slip contact, long service life, safe and reliable, etc.LVDT has excellent performance and adopts convenient single power source 9-28 V DC for power supply. With its electronic circuit sealed in stainless steel metal tubes, LVDT can work in the wet and dust and other extreme ambient. The output can be set into standard 0-5V voltage signal, 4-20mA current signal, or RS485 digital signal output and so on.LVDT displacement sensor has three basic types: split type, spring-back type and pneumatic type, and can be customized according to customer's requirements. The measuring range of LVDT split type is 0-500mm. It has the characteristics of water-proof, dust-proof and good dynamic performance. The measuring stroke range of LVDT spring-back type is 0-100mm. The contact probe adopts wear-resistant chromium plating hard tool steel. The measuring stroke range of pneumatic type LVDT is 0-15mm, and the working pressure is 0.15-0.7MPa.