Euroflex-The Flagship Press

Categories : Flexographic Printing Machines

The state of the art gearless flexo press and is one of the best valued gearless press on the market. As the flagship press is equipped with the highest automation, precision, stability, and cleaning technologies available. The press technologies along with its structural design allow for maximum press speed, working on the widest range of substrates. If you are looking for maximum efficiency and minimum human intervention, this is the press for you to customize. KYMC

Automatic Bag Packing Machine

FEATURES : 1. The outer structure of machine is shielded with SUS304 stainless steel which is easy to clean and maintain. The machine can be equipped with volumetric dispenser for solid, grain and liquid products. Solid/Grain ( CWM automatic computer weighing and filling machine). Liquid ( PF liquid, paste charging machine). Maximum loading per bag is 2000 gram. 2. Machine incorporates with bag feeding, filling, sealing1, sealing2 and discharging, all function works automatically. 3. Coding machine is optional. APPLICATIONS : Powder, Liquid, Grain, Sauce, Viscosity, Candy, Rice, Sugar, Salt, Bean, Coffee, Fertilizer, Frozen food, Seasoning, Meatball, Curry paste, Ketchup, Jelly, Shampoo, Detergent, Conserves, and other mixing products of liquid & solid. * Air compressor is not included.

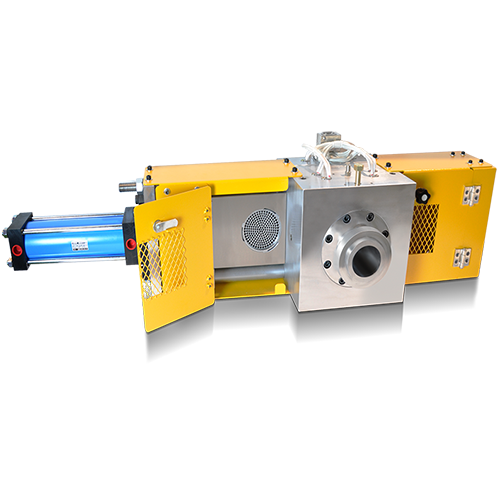

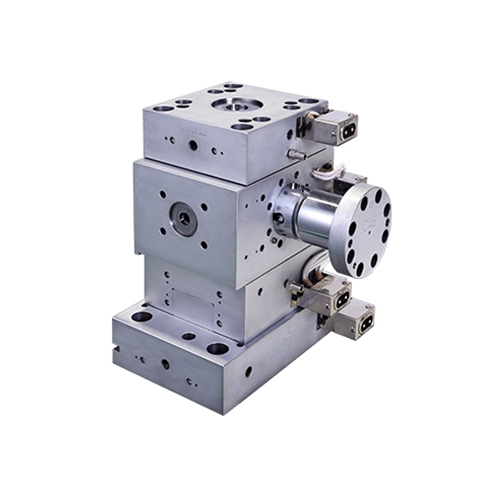

Screen Changer

Categories : Screen Changers / Filters

HYDRAULIC SLIDE PLATE Hydraulic system, easy for operation. Optional guard cover to provide highest safety operation. Materials : most polymer. Application : for extrusion products such as sheet and films. Hydraulic system, easy for operation. NON-STOP SLIDE PLATE Streamline and smooth channel for easy clean and little polymer stagnation. Interruption free and few bubbles caused by filter replacement. Hydraulic system with nitrogen accumulator for easy and fast operation. Fast slide plate movement for non-stop production. Materials : most polymer. Application : for extrusion products such as opitical, sheet and films. DUAL SLIDE PLATE Continuous production process. Interruption free filter replacement. Hydraulic system is driven by solenoid valve for easy operation. Optional guard cover to provide highest safety operation. Materials : most polymer. Application : suitable for sheet products. DUAL PISTON Continuous production process, air does not enter the production process. Interruption free by filter replacement. Hydraulic system is driven by solenoid valve for easy operation. Optional auto-venting system. Can be equipped with a fully automatic exhaust. Optional guard cover to provide highest safety operation. Materials : most polymer. Application : suitable for optical, sheet, film and other products. LARGE FILTRATION Continuous production process. Special venting design that no air enter the process during screen changing. Hydraulic system is driven by solenoid valve for easy operation. Optional auto-venting system.Can be equipped with a fully automatic exhaust. Can be equipped with a fully automatic exhaust. The filter area is about 2~5 times larger than the Dual Piston. Optional guard cover to provide highest safety operation. Materials : most polymer. Application : suitable for granulation, sheet, film and other products. BACK-FLUSH Interruption free filter replacement. Low pressure difference for stable and continuous production during filter replacement. Maintain 75% filtering area during filter replacement and backwash. Safety cover design improves operator safety. Automatic backwash and exhaust function for cutting filter replacement loss, operating requirements and scrap reduction. High wear-resistance, high pressure resistance, high-precision filter design provides effective filtering area and filter quality. Materials : most polymer. Application : suitable for recycle, granulation, packing tape and film. MANUAL WITH LEVER GEAR Easy operation with lever gear. Energy saving without driven system. Easy to clean when changing materials or colors frequently. Machine shutdown before filter replacement. Machine shutdown before filter replacement. Application : usually applied on sheet line, blow line and lab machine. SELF-CLEANING FILTER Interruption free filter replacement. Large filtering area, applicable with a larger mesh count. Manual back wash. Energy saving without driven system. Materials : most polymer. Application : usually applied on sheet , lamination and film line. CANDLE TYPE Compact mechanical design for higher mesh count to extend filter time. Manual network change, no hydraulic system. Adjustable pressure control during production to increase the effect of mixing in the screw. Application : applied on Lamination and film line.

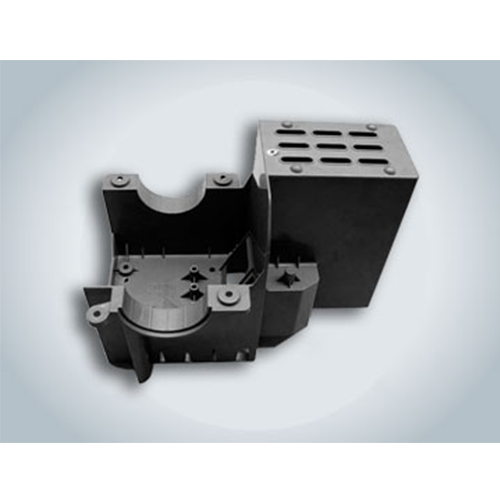

Fix / Variable / Rapid Geometry Feedblock

Categories : Extrusion Dies / Dies Heads

FIX GEOMETRY Simple manifold structure, few retention points Customized manifold design, 2 or 4 inlets, for different Extrusion Die inlet as required by the customer Precision internal manifold design along with special surface treatment Corrosion, heat and wear resistant design Manifold design varies with rheology property of polymer material to adapt to features and strength of rheology of melted polymers Applicable with multi-layer composite production requirements of different materials SUITABLE AVAILABLE FOR HEAT SENSITIVE POLYMERS INCLUDING ABS, PA, PC VARIABLE GEOMETRY Direct changing thickness of individual layers during production Easy operation, production costs reduction. Multi-layer space design according to product requirements. Interchangeable selector as required by customer to adapt to different products and changing layers required by the customer. Precision internal manifold design along with special surface treatment. Corrosion, heat, and wear resistant design. Adaptive to features and strength of rheology of melted polymers. Applicable with multi-layer composite production requirements of different materials. SUITABLE APPLICABLE WITH GENERAL POLYMERS SUCH AS PP/PE/PS RAPID VARIABLE GEOMETRY Direct changing thickness of individual layers during production Easy operation, production costs reduction. Multi-layer space design according to product requirements. Interchangeable selector as required by customer to adapt to different products and changing layers required by the customer. Precision internal manifold design along with special surface treatment. Corrosion, heat, and wear resistant design. Adaptive to features and strength of rheology of melted polymers. Applicable with multi-layer composite production requirements of different materials. SUITABLE APPLICABLE WITH GENERAL POLYMERS SUCH AS PP/PE/PS

GENERAL TYPE BLOWN FILM MACHINE

Categories : Blown Film Extruders

Applicable raw materials: HDPE, LDPE, LLDPE, EVA High-efficiency machine with high capacity but low energy consumption High-class gear box with enforced lubrication system and oil cooler Well-designed screw and barrel provide good mixing quality Nip rolls of adjustable height

HEAVY-DUTY BLOWN FILM MACHINE WITH OSCILLATING HAUL-OFF UNIT

Categories : Blown Film Extruders

Film width available from 2000 ~ 4000mm, excellent for heavy-duty bags. Unique die head and air ring design to achieve stable bubble and better even thickness film and bag. Gear box uses high torque and enforced lubrication system. Automatic surface winder with uploading device. Oscillating haul-off. Blown film machine with oscillating haul-off system, built under the supervision of professional European engineers. AC inverter motor is designed for high production, quality and reliability to produce tubular film. High torque gear box with enforced lubrication system to minimize machine shutdown time. Good mixing performance of screw and barrel results in homogeneity and high output. Oscillating haul-off unit allows minimum web tension that eliminates wrinkle or bulge problem. High volume air ring is designed for ideal cooling efficiency.

P-18

Categories : Injection Molds