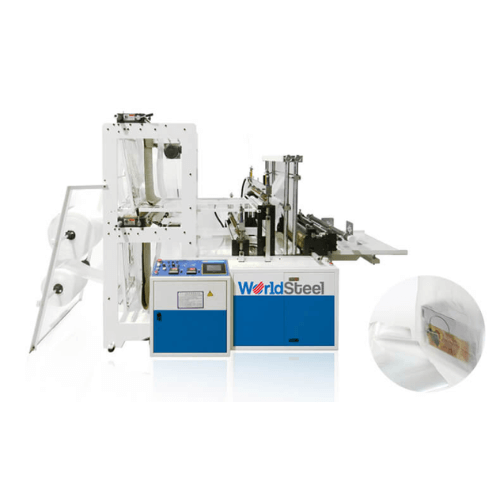

High Speed Automatic Bottom Sealing Bag Making Machine

Categories : Plastic Bag Making Machines

HIGH SPEED AUTOMATIC BOTTOM SEALING BAG MAKING MACHINE

S-16

Categories : Injection Molds

PVC Fiber Braided / Reinforce / Garden Hoses Extsuion Line

Categories : Extrusion Lines For Pipes and Profiles

Whole plant equipment includes extruder of inner pipe,cooling water tank,plastic wheel haul-off machine,wrapping yarn machine,oven,extruder of outer pipe,cooling water tank,blet type haul-off wheel,rooling machine,which are available for industry,agriculture and others.

2-Layer Mold Vacuum Compression Molding Machine

Categories : Compression Molding Machines

High steel 4-column style mechanism with high precision of parallelism. Adjustable daylight accommodates different height of molds. Diversified stripping device suitable for various type of molds opening.

Vertical Type Continuous Dryer

Categories : Dryers and Dehumidifiers For Plastic Materials

High efficiency dryer continues feeding wet materials and continues discharging materials improving traditional dryer to dry wet materials by lot saving your time and cost.

Plastic Machine Control System

Categories : Control Equipment

In the field of injection molding machine in China, the sales volume of...

MICRO MOLDING

Categories : Injection Molds

Micro molding is a very specialized art form, which is a kind of tooling design , manufactures small and precision plastic components with polymer-based functional devices, by increasingly demanded in the fields of life science, electronics, medical, photonics, automotive, and aerospace. The tiny-scale molding form of injection molding that entails building a cavity to match the shape of the part you want to make, sort of like the plastic molding that makes Lego bricks. THERE ARE THREE DIFFERENT THINGS TO KEEP IN MIND WITH MICRO MOLDING : Micro means the size of the part. It is the most common definition when dealing with micro molding. Micro features relates to tiny parts on a larger part. As a whole, the part can be big, but its components can be smaller, or micro features. Micro tolerance is how the parts are measured and how close to the needed measurement the part has to be to be considered a good or usable part. When a part is molded, it has to measure within the needed measurement (the tolerance), which could be as small as a thousandth of an inch. Small parts that are simple to make have tolerances that are not as tight and would be considered regular molding. SOME ADVANTAGES OF DESIGN GUIDE IN YOMURA AS : Dimension Aspect ratios around 6:1 (material dependent) Wall thickness : 0.3 mm ( 0.012”) min. for plastic Hole dimension : 0.2mm ( 0.008”) – 0.5mm ( 0.02”) min. Pitch of hole : 0.3 mm ( 0.012”) – 0.50 mm ( 0.02”) min. Tolerance (min) : 0.01 mm ( 0.0004”) – 0.02 mm ( 0.0008”).

All Electric Automation Composites Forming Machine

Categories : Compression Molding Machines

Designed with independent ceramic heating system for quick materials preheating. Equipped with heating and cooling system to meet the different forming process, the key to make TPC products with high surface requirement.