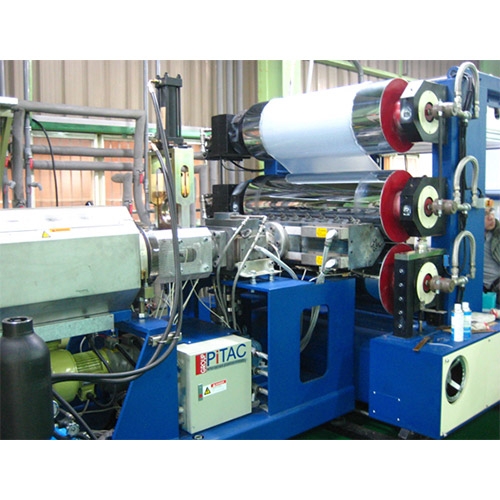

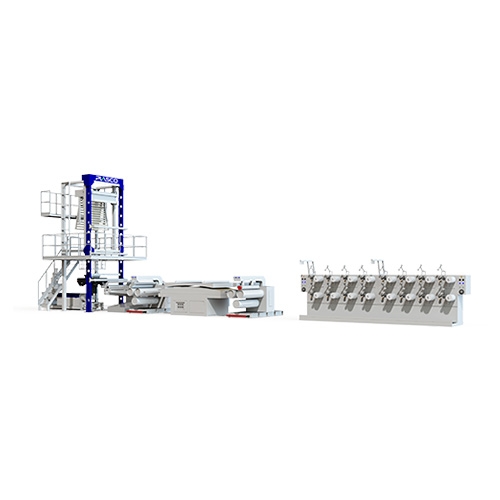

Rigid Sheet Extrusion Line

Categories : Film and Sheet Extrusion Lines

1. Extruder is driven by AC Inverter duty motor, with excellent efficiency and lowest power consumption. 2. Extruder hopper with low-level sensor work with auto-feeder will keep material in stable supply. 3. Hydraulic driven screen changer avoid any particle goes to melting pump & flat-die. 4. Melting pump with accurate rotation control, keeps the material flow stable. 5. Extruder & melting pump speed is working on pressure synchronized controlling system.

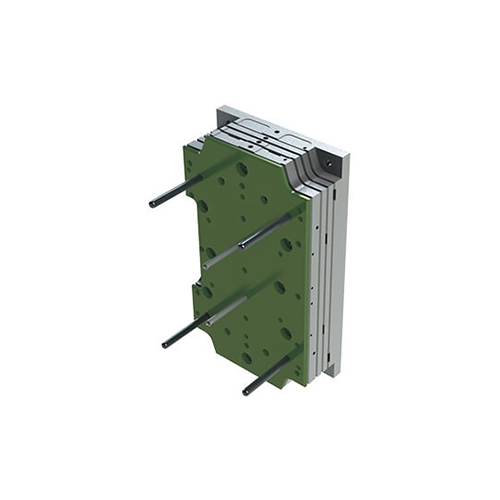

COLD DECK WITH 2 VALVE GATES

Shut-off nozzle design:Don't need to cut scrap. System temperature analysis:High efficiency heat isolation and cooling, uniform heating system. Module design of Cold Deck:Quick installation and easy to maintain.

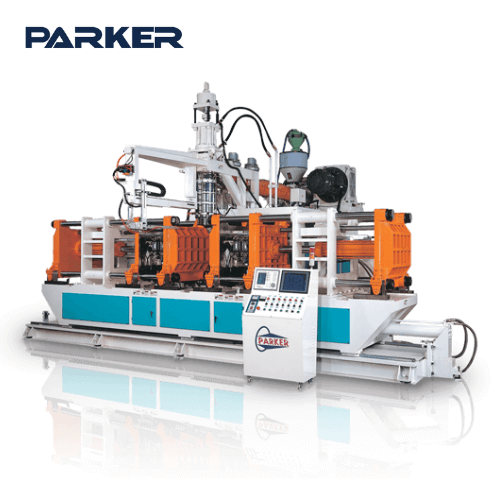

Tying Tape & Twine Extrusion Line (JC-BFY Series)

Categories : Blown Film Extruders

The JC-BFY series tying tape extrusion line by blown film extrusion process is speically designed to produce tying tape, polytwine, twisted twine for light packaging applcation, as well other general packaging and industrial application.

WT - 480, 600, 720

Categories : Cooling Equipment / Industrial Chillers

Temp. Range: 5~40°C Humidity Range: 40~80% Cooling Capacity: 112~209 KW

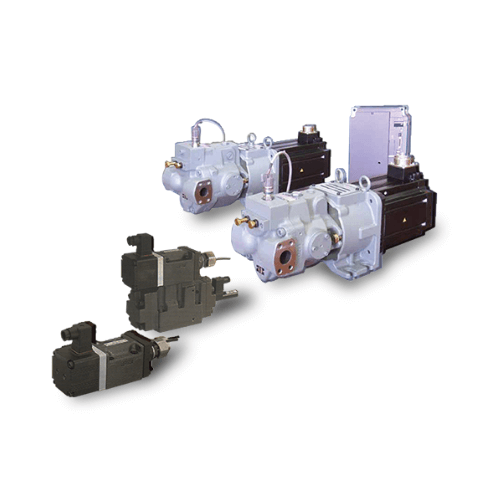

Hydraulic Servo Energy Saving System

Categories : Pumps

Pioneer products that lead the plastics machinery industry to energy-saving, green-environmental protection.

AT - 24, 36

Categories : Cooling Equipment / Industrial Chillers

Temp. Range: 5~40°C(Indoor ) Humidity Range: 40~80% Cooling Capacity: 5.6~10.5 KW

PET Preform Neck Crystallization Machine - CR Series

Categories : Crystallizing Machines

● Economic and energy saving, compare with other crystallized machine help save energy. ● Through star wheel, stable and smooth to transport system.

PA6/66 (Ultra Impact Modified Grade)

Categories : PA(Polyamide) /Nylon

Increase the toughness of nylon at low temperatures.

Primary Packaging–General - Filling/Closing - CJ-250

Categories : Capping Machines

The liquid packaging equipment compliances with cGMP liquid production guidelines and the common application is for above 60mL low viscosity products.