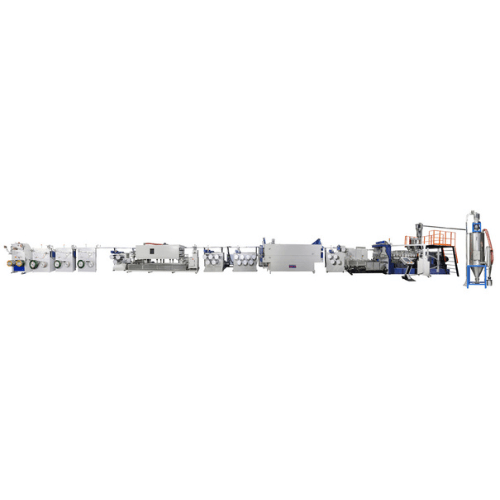

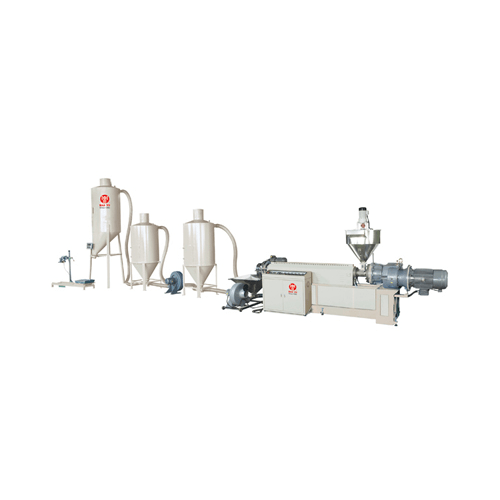

Classification : Wood Plastic Composite Profile Extrusion Line

Country: Taiwan

Phone: 886-4-2630-3998

Fax: 886-4-2630-1410

Contact Person: Mr. Franky Chi

The wood plastic composite products and manufactured through extrusion process, which is ideal for bulk production. Besides, product diversity cab be obtained effortlessly-simply mounting different mold heads. We provide molds for different WPC profiles which are used as flooring, wall panel, skirting board, strips, bars and so on. The WPC profile extruder machine can choose the molds and replace by easy operation, efficient and effective WPC production is just at your fingertip.

-

Main Extruder

Main Extruder -

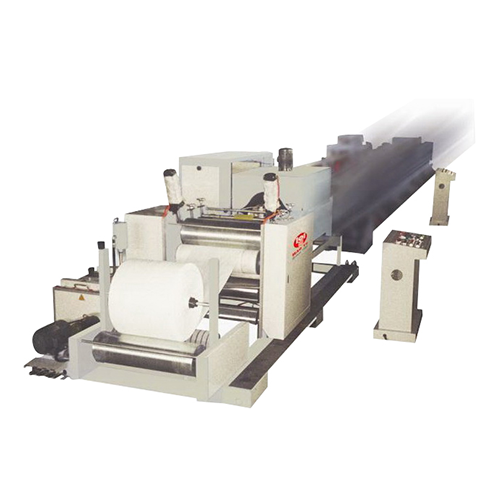

Cooling Station

Cooling Station -

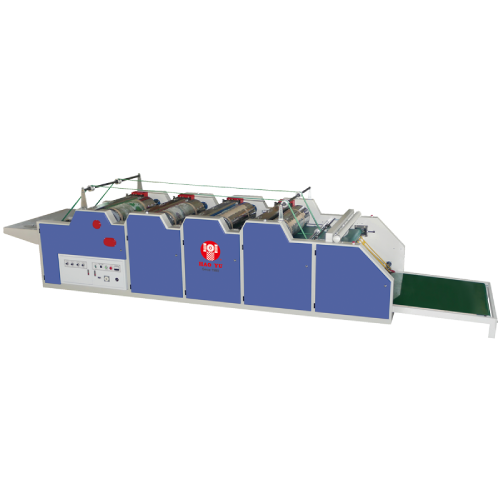

Take-off Unit

Take-off Unit -

Cutting Device

Cutting Device -

Stacker

Stacker

- The new plastic-wood composite is similar to wood in look, feeling and smell, but with better performance than wood.

- Resistant to water, insects, corrosion and mildew.

- Ideal for applications in high moisture environments.

- Lightweight and durable.

- Superior dimensional stability.

- Recyclable to meet environmental protection requirements.

- No surface finishing is required.

- Functions same as natural wood, but with more advantages.

| Model | HY7-WP70 | HY7-WP100 | HY7-WP120 | HY7-WP150 |

|---|---|---|---|---|

| Extruding Capacity(kgs/hr) | 30~65 | 70~100 | 90~140 | 130~200 |

| Screw Diameter(mm) | ø70 mm | ø100 mm | ø120 mm | ø150 mm |

| Screw L / D Ratio | 25:1 | 25:1 | 25:1 | 25:1 |

| Barrel Vacuum System | Equipped | Equipped | Equipped | Equipped |

| Driving Motor | 20 HPwith inverter | 50 HPwith inverter | 60 HPwith inverter | 75 HPwith inverter |

| Temperature Control(points) | 6 | 7 | 9 | 10 |

| Take-Off Unit | Caterpillar | Caterpillar | Caterpillar | Caterpillar |

| Driving Motor | 3 HP with inverter | 5 HP with inverter | 5 HP with inverter | 5 HP with inverter |

| Cutting Device | Pneumatic control | Pneumatic control | Pneumatic control | Pneumatic control |

| Driving Motor | 2 HP | 2 HP | 3 HP | 3 HP |

Design and specifications are subject to change without prior notice.