-

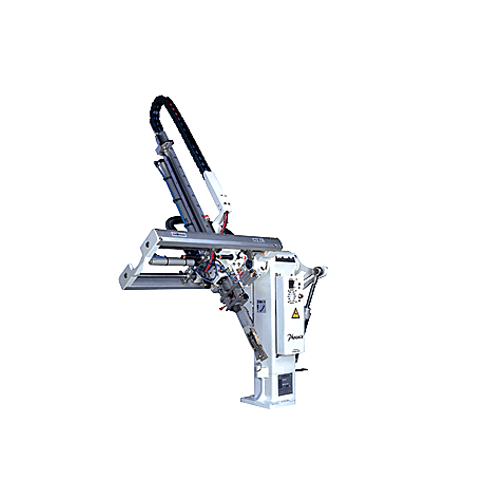

Optimally engineered structural design allows effortless adjustment of gripping orientation.

-

An easy and quick tip for changing the orientations: using a 17mm wrench to remove and install fixing nuts by turning them 50-90 degrees once, after the gripper is moved to a desired position.

-

The gripper rotates 50-90 degrees.

-

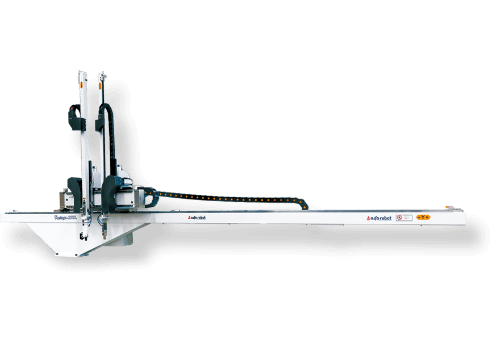

A paired controller (CD-EMI) offers easy operation.

-

An easy job as well, changing programmed robot motions can be completed only with 3-5 keys on the on-screen keyboard.

-

With 15 timing modules, accurate and precise motion planning is made possible.

- Control parameters can be tuned during the programmed motion and without the need for shutting down the robot

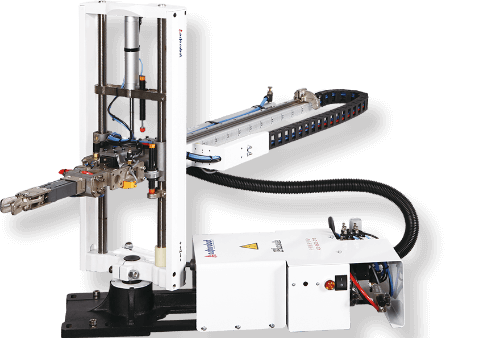

|

MODEL |

UX-30 |

UX-60 |

UX-150 |

|

ITEM |

UX-30/UXF-30 |

UX-60/UXF-60 |

U-150/UXF-150/UXF-150G |

|

Molding Machine Size (ton) |

10-30 |

50-90 |

80-150 |

|

A. Full Length |

480 |

||

|

B. Full Width |

540 |

620 |

740 |

|

C. Height of Main Arm |

1150 |

1250 |

1350 |

|

D. Height of Sub Arm |

X |

X/1350 |

|

|

E. Max. Radius of Products Handled |

292/357 |

292/357 |

342/407/407(342) |

|

F. Min. Distance b/w the Arms |

X |

X/60 |

|

|

G. Standby Position of Main Arm |

0-235/0-170 |

0-235/0-170 |

0-185/0-120/0-120 |

|

H. Standby Position of Sub Arm |

X |

0-185 |

|

|

I. Distance b/w Main arm and Base |

X |

||

|

J. Distance b/w Sub Arm and Base |

X |

||

|

K. Vertical Stroke of Main Arm |

350 |

450 |

550 |

|

L. Vertical Stroke of Sub Arm |

X |

X/X/550 |

|

|

M. Min. Distance from Sub Arm to Base |

X |

X/X/60 |

|

|

N. Min. Distance from Main Arm to Base |

62 |

60/60/150 |

|

|

P. Max. Demolding Stroke |

190 |

270 |

390 |

|

Q. Controller Width |

250 |

||

|

R. Controller Height |

935 |

||

|

S. X Axis Width |

232 |

||

|

T. Y Axis Width |

900 |

||

|

U. Z Axis Height |

500 |

||

|

V. Base Width |

125 |

||