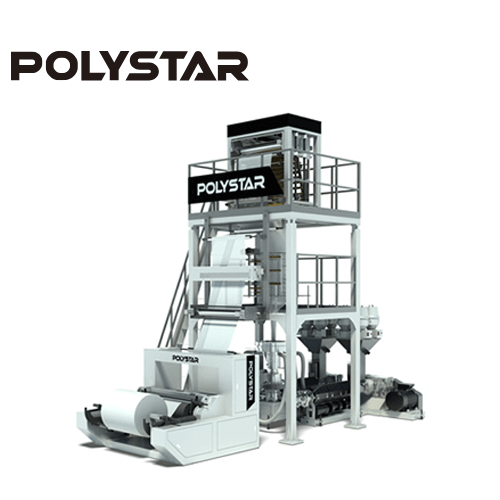

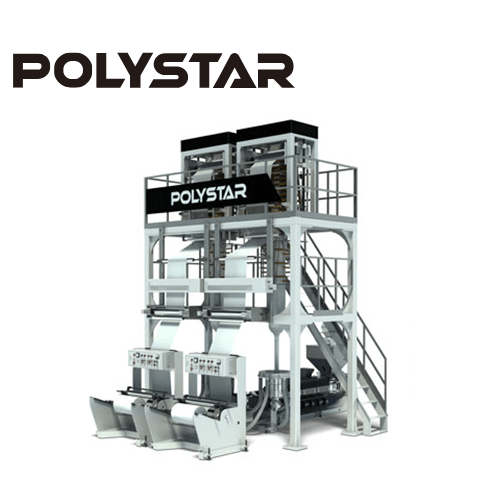

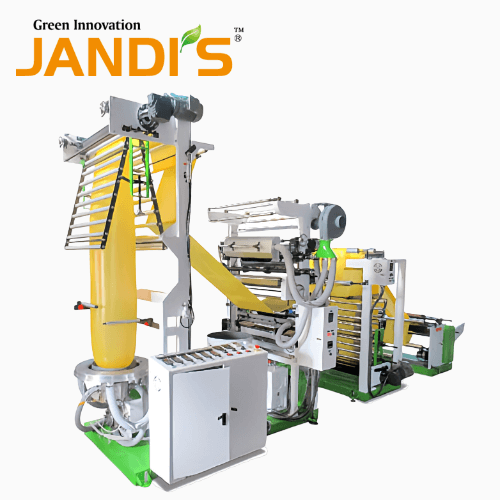

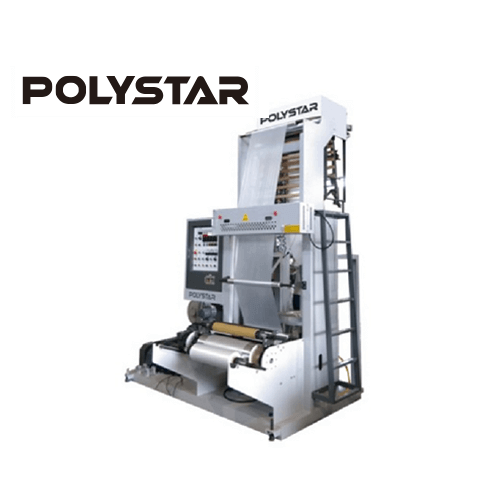

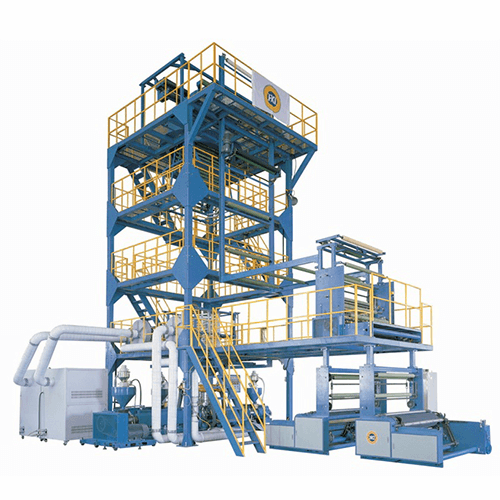

King-Plus LES series is designed to produce LDPE plastic film, while HES series for HDPE plastic film. These machines could give you advantages with high-quality, extraordinary mixing performance and high output capacity. With precise machinery design, they could work in efficiency state to realize the achievement of saving energy.

HDPE & LDPE film is commonly used to shopping bag, garbage bag, surface protection film, industrial packaging and agricultural film etc.. There are some auxiliary options as like rotary die seat, oscillating haul-off device, auto loader, gusset device, embossing device and auto roll change device and so on, to build a especially-suitable blown film machine for you.

● Case in LDPE machine.

Single layer LDPE 65mm extrusion

- Width 1500 mm x thickness 0.056 mm = 200 kg/hr

- Width 1000 mm x thickness 0.04 mm = 130 kg/hr

| Model | LES-45 | LES-55 | LES-65 | LES-85 | LES-100 |

| Film width | 600~1000 mm | 1000~1600 mm | 1400~2200 mm | 1800~2500 mm | 2200~3500 mm |

| Film Thk. | 0.02~0.2 mm | ||||

| Max extrusion output | 110 kg/hr | 160 kg/hr | 230 kg/hr | 320 kg/hr | 420 kg/hr |

| Max formal output | 90 kg/hr | 140 kg/hr | 200 kg/hr | 300 kg/hr | 400 kg/hr |

| Average power consume | 25 kw | 40 kw | 58 kw | 85 kw | 120 kw |

| Cooling water consume | 6 L/min | 8 L/min | 10 L/min | 14 L/min | 16 L/min |

- Laundry bag

- Shopping bags

- Agricultural film

- Packing film