Classification : PP/HDPE Woven Bag Making Equipment

Country: Taiwan

Phone: 886-5-2215139 /886-5-2215149

Fax: 886-5-2219259

Contact Person: Ms. Lee

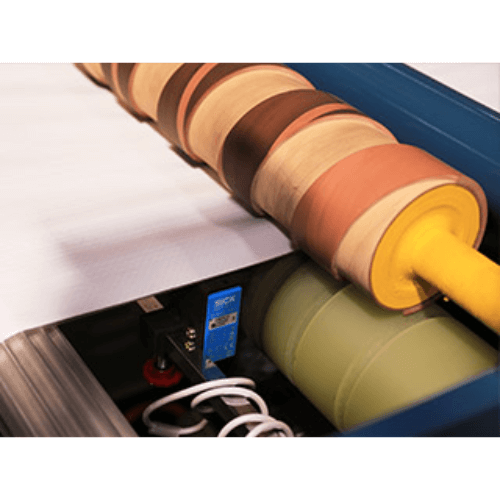

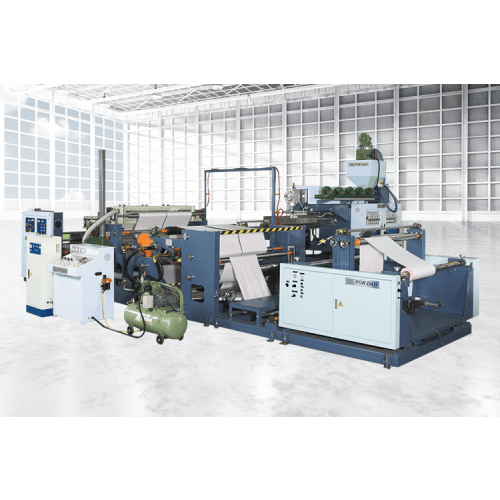

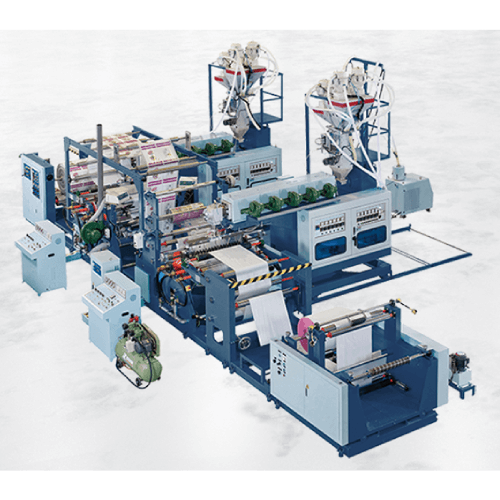

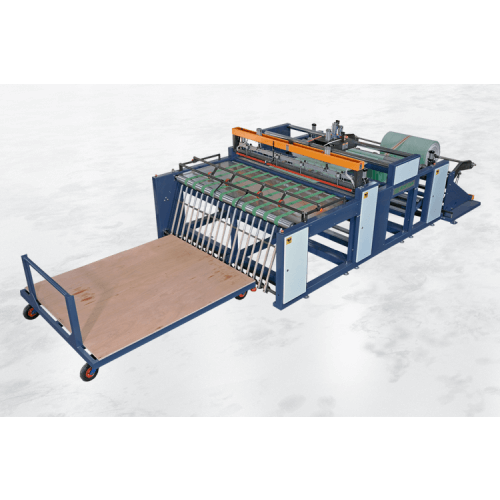

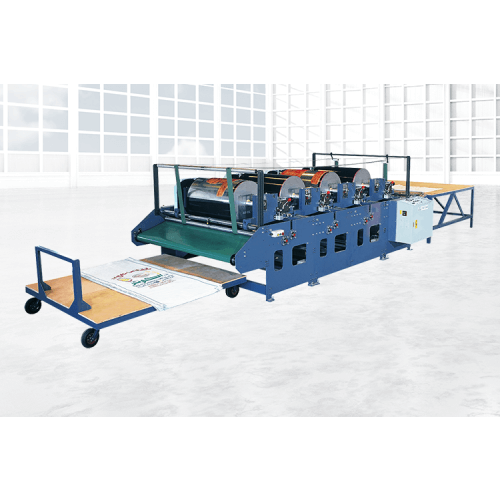

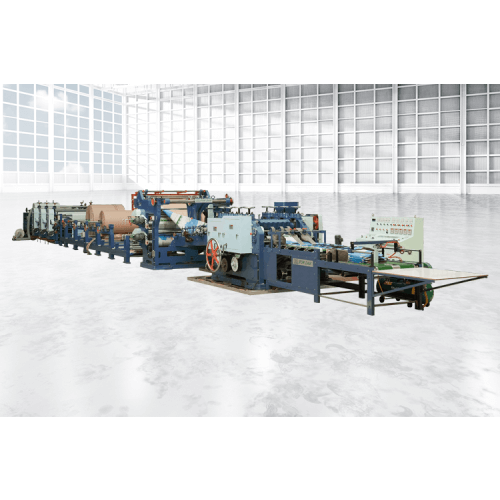

The single side flexographic 4~6 color roll to roll printing machine is applied for solvent-based ink and direct printing method without changing plate cylinder for printing PP woven bag with/without lamination. The printing quality is more beautiful with simple CMYK color combination than piece to piece printing.

- No need to change plate cylinder if the bag length is different.

- Available to print double side by two times with printing tracking system to match the position.

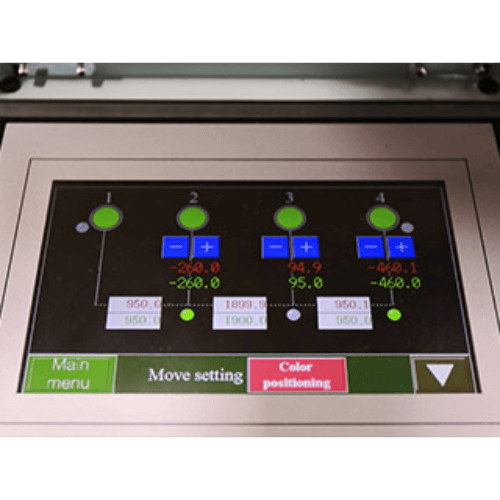

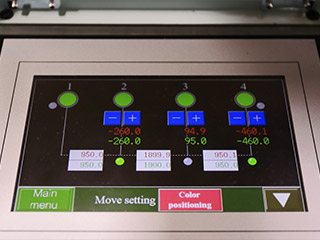

- Fully digitalized control setting on operator-friendly human machine interface (HMI).

- Independent hot air oven to dry the front side and back side of woven cloth at one time.

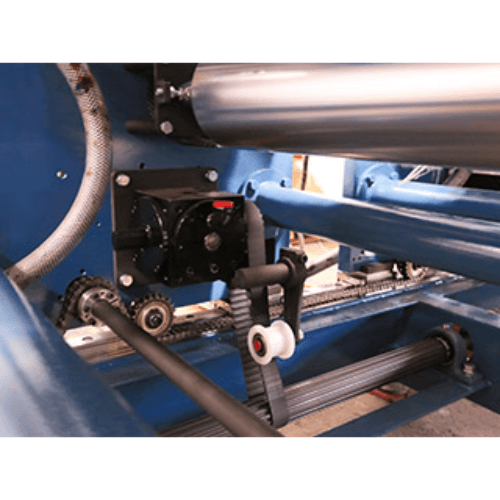

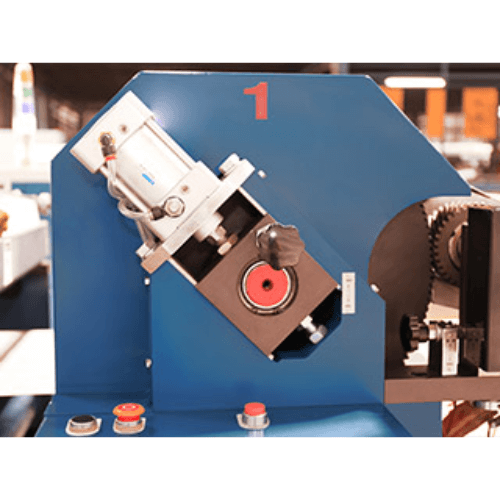

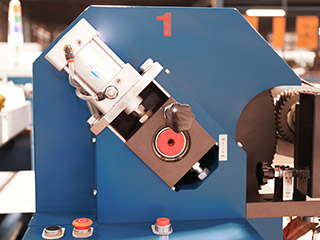

Cubic Differential Transmission

Printing Mark Sensor

Manual Printing Registration System without Stopping M/C

Auto. Ink Pump Circulation

| Model | |

|---|---|

| No. of Color | 4+0 |

| Max. Web Width | 970 mm |

| Max. Printing Width | 950 mm |

| Printing Repeat | 300~1400 mm |

| Max. Printing Speed | 50 pcs/min |

| Max. Roll Diameter | ∮1300 mm |

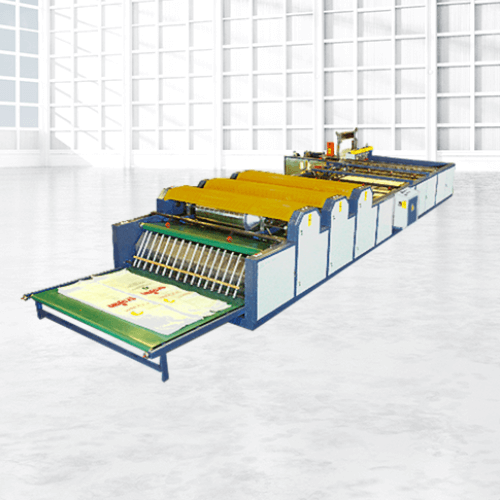

Included Device

- Colored Touch Screen Type Industrial Computer Operation System (HMI) x 1 set

- Electronic Control System

- Pneumatic Control System

- Auto. Ink Pump Circulation: (Quantity depends on printing color)

- Auto. Web Guiding System Before Printing x 1 set

- Auto. Hydraulic System for Separating Ink Roller and Anilox Roller x 1 set

- Manual Printing Registration System without Stopping Machine

- Plate Cylinder: (Quantity depends on printing color)

- Viscosity Test Cup (Manual) x 1 pc

Optional Device